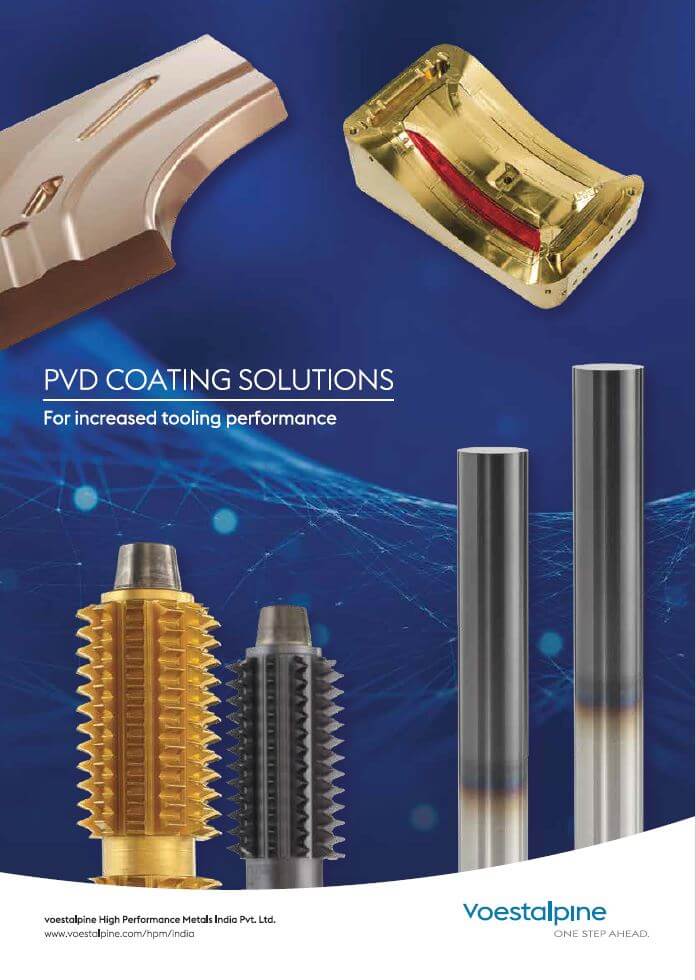

PVD Coating

voestalpine eifeler Coating

With the acquisition of eifeler by the voestalpine AG, we are one of the leading suppliers of PVD coatings. Since 1983, we have not only been engaged in coating of surfaces, but also continuously set new standards in research and development. It’s therefore no surprise, that today eifeler technology is synonymous with high-tech and premium products.

Why PVD Coating?

PVD coatings (Physical Vapor Deposition) have been established for years in almost all markets and industries to improve the durability and performance of tools and components of all kinds.

PVD coating is a vacuum coating technique, in which a film is created to maintain a harder surface on the target material. This film extends the life of the tool, lowers tool maintenance and improves overall part quality. The environment that may otherwise be able to perform in.

An irreplaceable quality of PVD coatings is that it uses lower temperatures for the application process avoiding the disadvantages of procedures such as CVD coating, in which the tool has to go through the process of becoming soft post-coating, and then re-hardened again – putting it at risk of becoming distorted.

Our Capability:

Our PVD Coating Center specializes in creating custom coatings for the automotive, firearm, die casting and plastic injection tooling industries. We are equipped to accommodate a wide variety of customer needs. The coating center operates alongside the company’s steel divisions. Offering an unparalleled level of service compared to any special steel company worldwide.

Our coating center is equipped with:

- Alpha 900 (Ø 750×880)

- Alpha 400 (Ø 450×485)

We are specialized in ultrafine coating and have 7 stage cleaning line

Your Benefits

- Combination with friction-reducing layers possible

- Variable layer structure (nanostructures, multilayer, monolayer)

- Chemical and mechanical decoating possible

- Very good adhesion to the substrate

- Very good impression of textured and polished surfaces

- Very good dimensional accuracy and contour accuracy

- No hardness drop

- No influence on the microstructure with suitable material selection

Get in touch with us now to find the right solution for you.

OUR PVD COATING PORTFOLIO

| Coating | Material | Micro-hardness HV0.05 | Coeff. of friction vs. steel | Coating thickness [µm] | max. Operating temperature | Color | General characteristics | Recommended application |

|---|---|---|---|---|---|---|---|---|

| TiN | TiN | 2300±200 | 0.6 | 2 – 4 | 500°C | gold | Allrounder, biocompatible | ● Forming of steel parts |

| TiCN | TiCN (multilayer) | 3500±500 | 0.2 | 2 – 4 | 400°C | blue-grey | High hardness, excellent wear resistance, improved load-bear capacity | ● Forming of abrasive materials and stainless steel ● Lubricated milling of steel |

| CrN / CrCN | Cr(C)N (multilayer) | 2000±200 (2300±200) | 0.2 – 0.3 | 2 – 6 | 600°C | silver-grey | Low residual stress, high adhesion, extremely high resistance against corrosion | ● Especially for non ferrous- materials |

| EXXTRAL® | AlTiCrN (layered) | 3200±300 | 0.4 | 2 – 5 | 800°C | anthrazite | High hardness, high oxidation resistance, low coeff. of friction | ● Forming of abrasive materials and materials with high sticking affinity ● Dry milling of steel |

| SISTRAL® | AlTiN (nano-structured | 3400±500 | 0.7 | 2 – 4 | 900°C | anthrazite | High oxidation resistance, high warm hardness, high wear resistance | ● High performance coating for machining of steel and Ti ● Very well suited for punching and fine blanking of steel |

| ZrN / ZrCN | Zr(C)N (multilayer) | 2800±200 (3100±300) | 0.5 | 2 – 4 | 600°C | light-yellow/brown-silver | Reduced affinity of cold welding, high resistance against corrosion | ● Mg die casting ● Machining of Al |

| CROSAL® -plus | AlCrN(basiert) | 3200±300 | 0.45 | 2 -5 | 1100°C | Slate-grey | Extremly high resistance against oxidation, high warm hardnes, high wear resistance | ● Processing of steel parts at high temperatures ● Dry cutting of steel; hobbing |

| SUBLIME® | AlCrN(basiert) | 3200±200 | 0.7 – 0.8 | 2 -5 | 1100°C | Grey | Extremly high resistance against oxidation, high temperature wear resistance | ● Processing of steel parts at high temperatures ● Dry cutting of steel; hobbing |

| TIGRAL | AlCrTiN(nanolayer) | 3300±300 | 0.6 | 3 -5 | 900°C | grey | High resistance against oxidation, high warm hardnes, high wear resistance | ● Processing of steel parts at high temp. ● Al die casting |

| TOPMATIC | TiAlN | 2800±200 | 0.4 | 5 – 9 | 800°C | aubergine | Excellent toughness, good resistance against oxidation, high wear resistance | ● Massive forming of steel ● Higher coating thickness |

| VARIANTIC® | TiAlCN (multilayer) | 3500±500 | 0.2 | 2 – 4 | 800°C | old-rose | High oxidation resistance, low coeff. of friction | ● High performance coating for deep drawing and forming of high and low alloyed steel grades |

| VARIANTIC® 1000 | TiAlCN (multilayer) | 40000±500 | 0.05 – 0.15 | 8 – 10 | 800°C | old-rose | low coeff. of friction, excellent abrasive and adhesive wear resistance | ● High performance coating for deep drawing and forming of high and low alloyed steel grades |

| DUMATIC | TiN/TiC (multilayer) | 3700±200 | 0.3 | 3 – 5 | 400°C | silver-grey | High hardness, excellent adhesion to the substrate, low coefficient of friction | ● Forming of high-alloyed CrNi-steels ● Punching of thick sheet metals and massive forming of steel |