Duplex Treatment

Plasma nitriding + PVD coating

The combination of a thermochemical plasma nitriding process with the following deposition of a voestalpine eifeler PVD coating in a non-interrupted vacuum system process we call duplex treatment.

The surface hardness of the tool material is definitively increased, which contributes considerably to the increase in performance of the Duplex PVD coating.

Therefore, we developed a nitriding process, suitable for this procedure and applied it on our alpha 400 and alpha 900 coating systems, where it is performed before the coating process. Basically, all coating- and nitriding-capable steel materials are suited for this process.

Tools are an application emphasis for which this procedure currently is selected regularly and successfully for the forming of high-strength sheet materials. VARIANTIC® or TiCN is often utilized in this manner.

Combinations with other coatings are also possible. For consultation in concrete applications, our executive consultants are available to you at all times.

The following advantages result for you:

- Ideal structure of a hardness gradient from the tough-hard tool core, through a higher supporting hardness in the interface, extending to the extremely hard and wear resistant tool surface.

- A considerably increased support effect therefore results for the extremely hard and brittle ceramic wear protection layer.

- The absorbing ability for pressure loads increases significantly!

Some Applications of Duplex Treatment

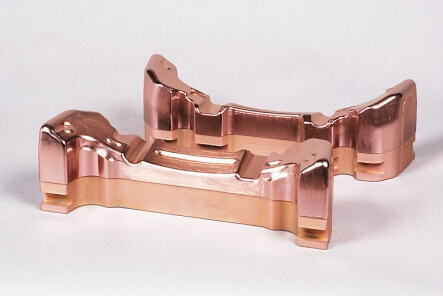

Blankholder: Segmented tool

Drawing tool: Segmented tool

Treatment DUPLEX-VARIANTIC: Mirror finish in assembled status, 1. 2379, Base hardness 58-60 HRc

Workpiece material: CPW 800; 1.7 mm

Lubrication: minimum coil greasing (2 g / m2)

Status quantity: > 120,000 parts

Result: The optimized and hard-coated surfaces do not indicate any visible wear traces.

In comparison without coating: A repolishing of the functional surfaces is required every 5000 parts.

Drawing tool: Segmented version

Treatment DUPLEX-VARIANTIC: Mirror finish in assembled status, 1. 3343, Base hardness 63-64 HRc

Workpiece material: CPW 800; 1.8 mm

Lubrication: Coil greasing, slight oiling

Status quantity: > 300,000 parts

Result: The optimized and hard-coated surfaces do not indicate any visible wear traces. Segmented version.

Substrate: D2 (1.2379), 58-60 HRc

Part: wishbone part, car, CPW 800, 4 mm

Tool: mirror polish by voestalpine eifeler

Coating: Duplex-VARIANTIC

Result: > 1 Mio. parts

Total dimensions: 2500 mm x 1100 mm x 630 mm

Drawing rings: Ø 90 – 100 mm x 70 – 80 mm

Treatment DUPLEX-VARIANTIC: Mirror finish Vanadis 6 / Vanadis 10, Base hardness 62+ 2 HRc, Workpiece material: 1. 4301-DDQ-2 blank Ø 144 mm x 2.6 mm

Lubrication: Esso – drawing oil 60

Status quantity: > 100,000 parts

Result: No visible wear on the coated active segments