Surface Treatment

HEAT TREATMENT – Imparting soul to steel

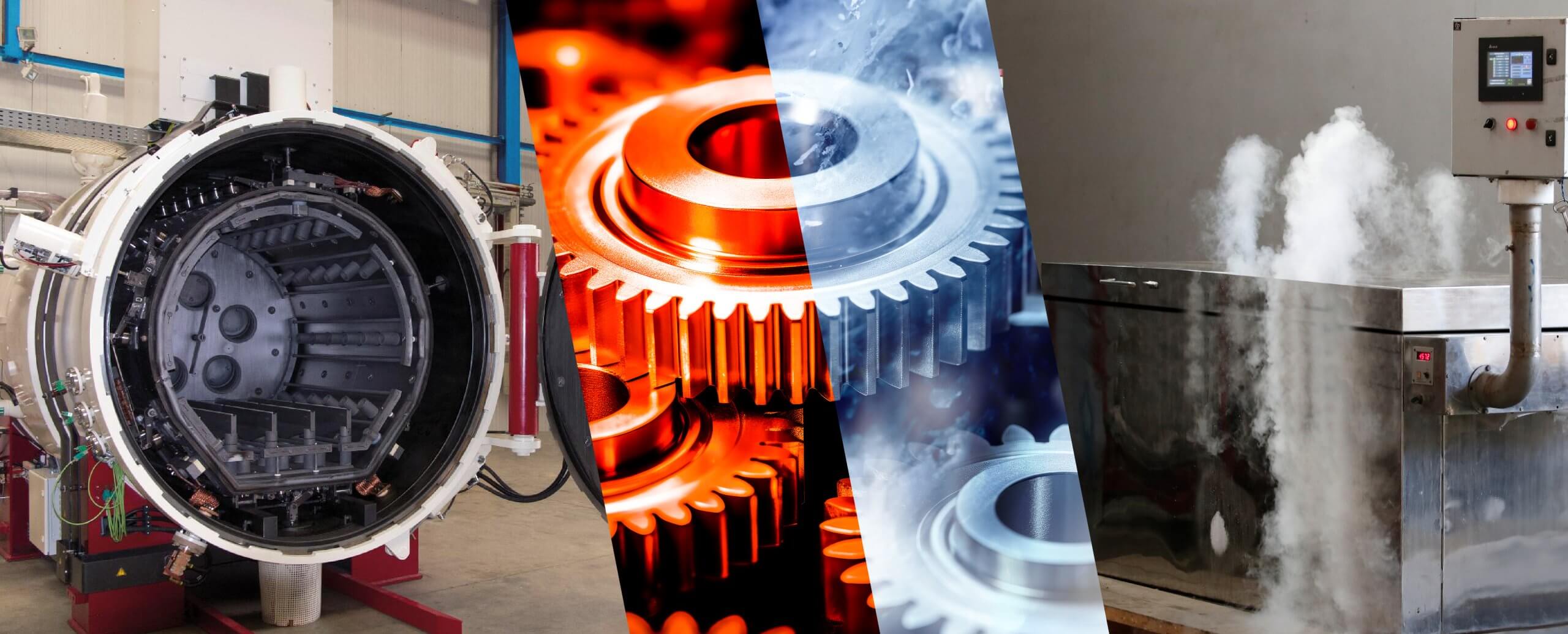

Heat Treatment process is in which metallic/steel parts are exposed completely or partially to time temperature sequences in order to change the mechanical and/or corrosion properties resulting in higher strength of the material, better wear resistance and improves the corrosion behaviour of the component.

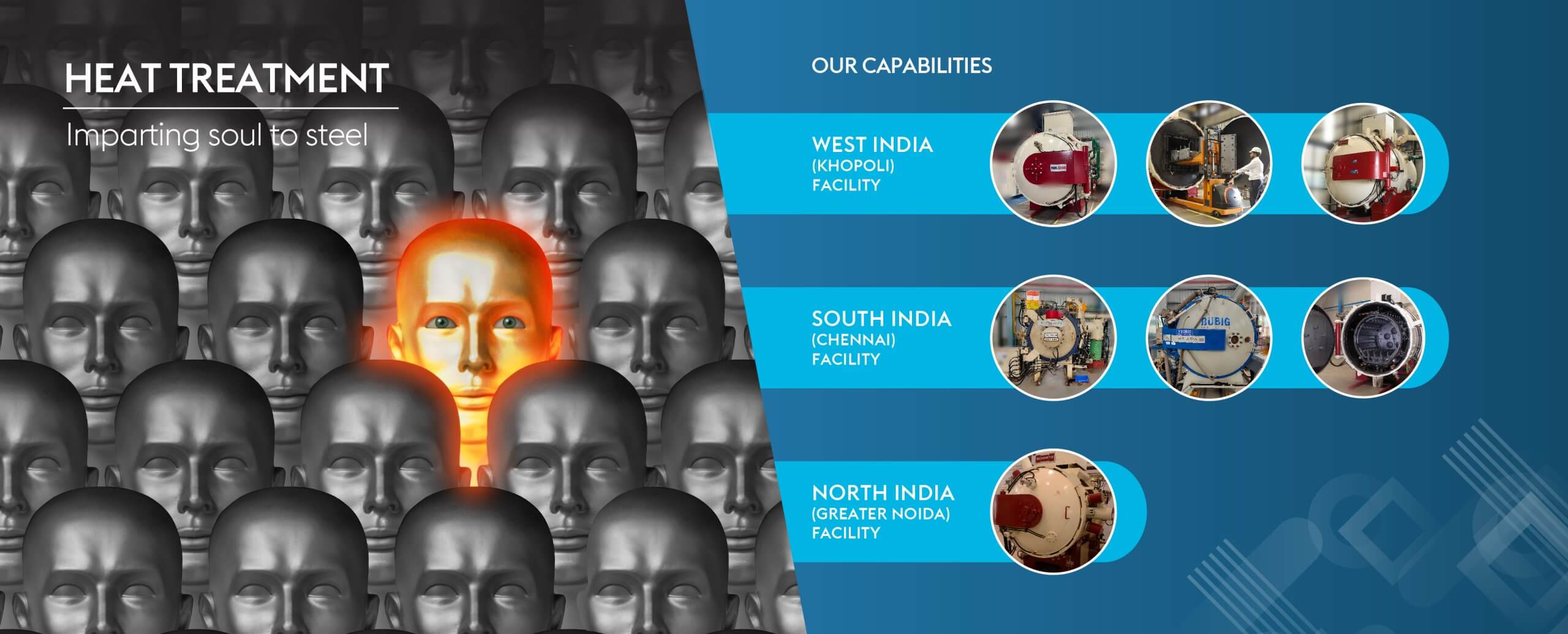

We provide solutions like

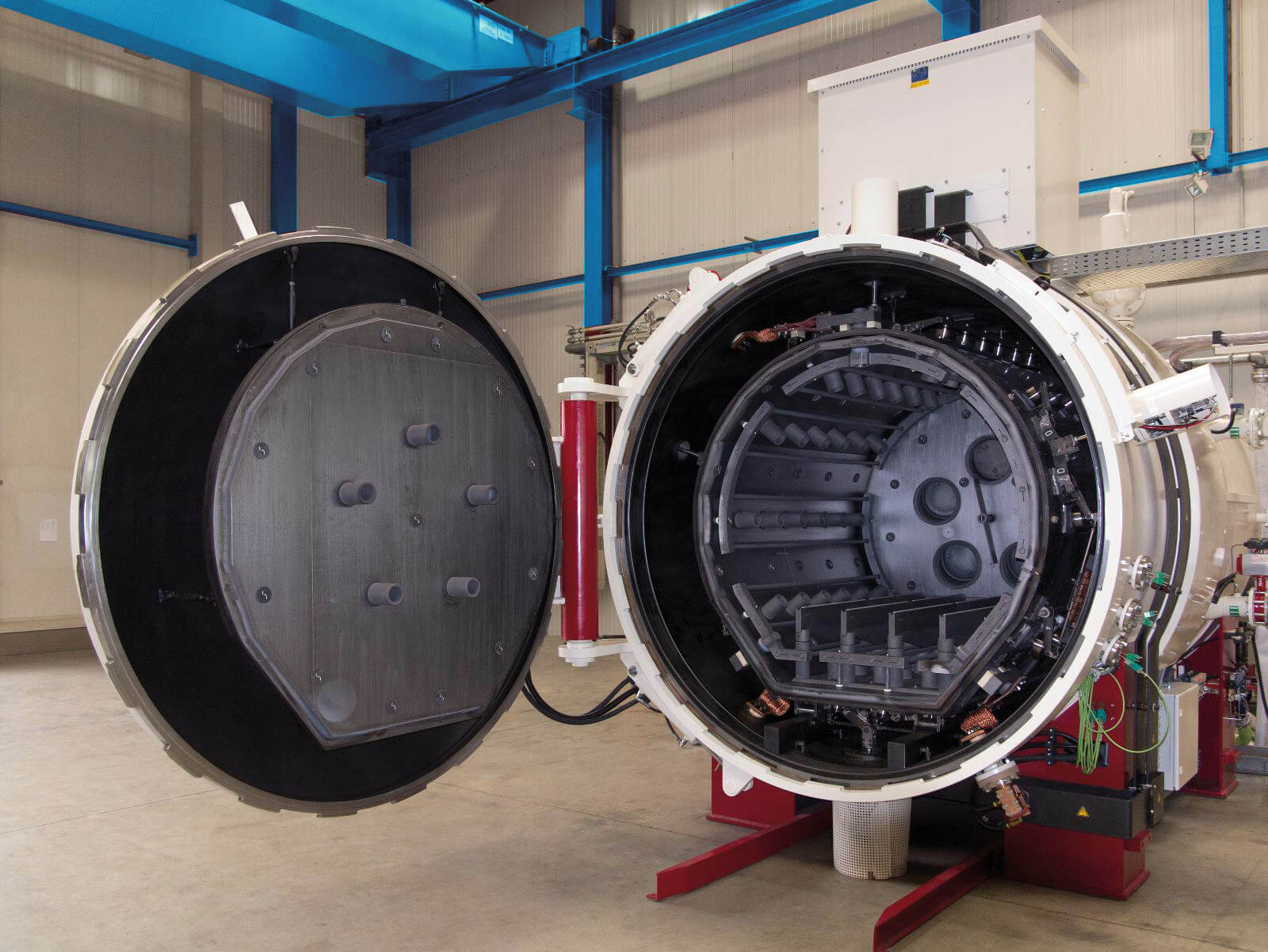

- High pressure vacuum hardening – Our VHT process helps you achieve higher strength of material, better wear resistance and improved corrosive behavior of the components.

- Cryogenic treatment – The process is not just a surface treatment but it affects the entire mass of the tool or component being treated, making it stronger throughout.

- Stress relieving – Stress Relieving is the process which is carried out to remove the mechanically induced stress. It should be performed twice to get maximum benefit, once after rough machining and then again before semi-finish machining.

It’s very important to have the right heat treatment done based on application, for achieving optimum tool life from good tool steel. We follow global standards for our heat treatment process; Our engineers are well trained in India and abroad. We heat treat Tool steels and Special steels for variety application.

All our equipment and process are periodically validated and calibrated. We deliver as package of steel tool and heat treatment with the right tooling solution. We render good technical and logistics support to customers for tool life improvement.