LASERtex

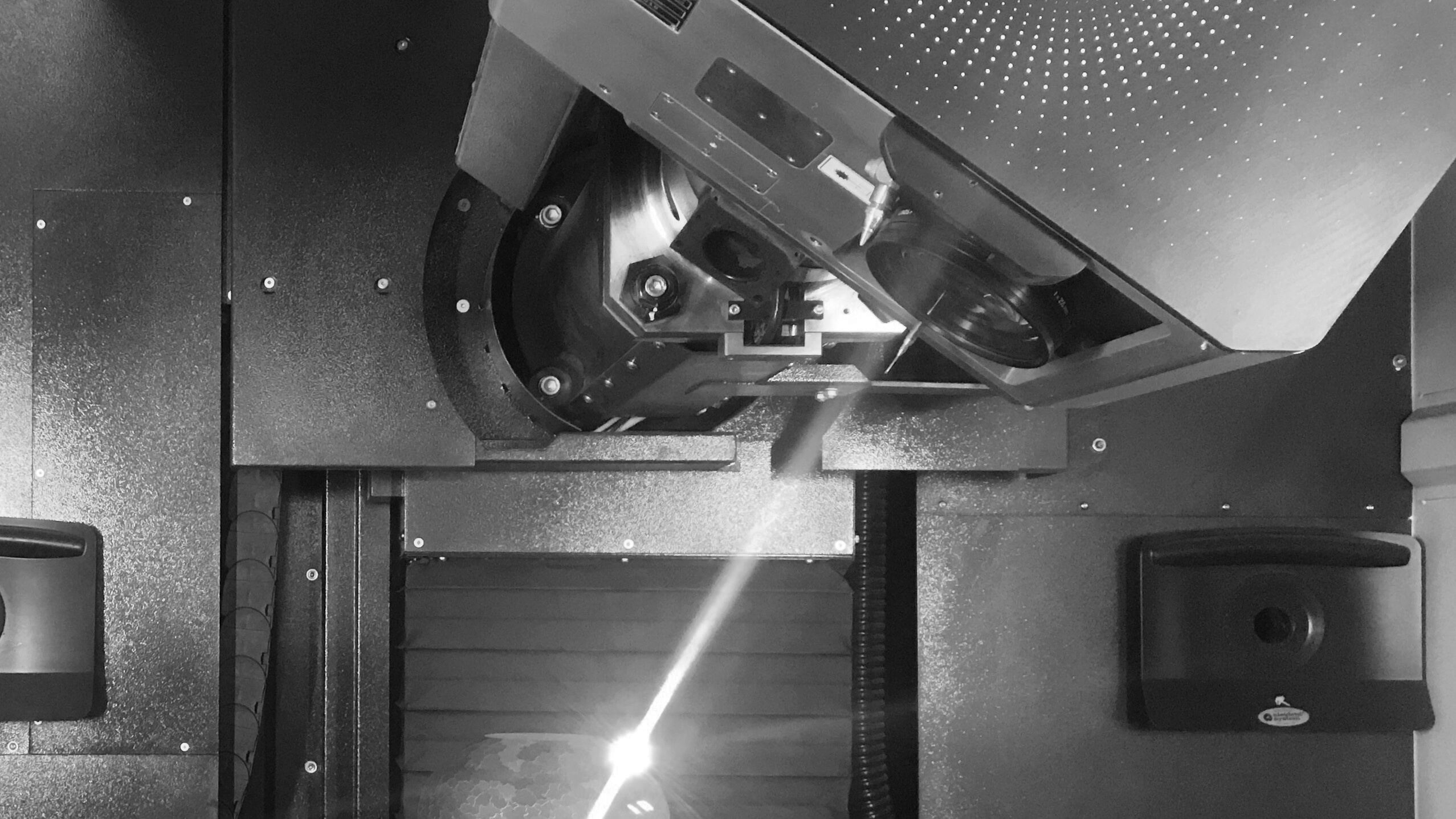

Worldwide biggest 5-axis FEMTO laser machine

NEW HORIZONS FOR TEXTURE APPLICATIONS

Our modern LASERtex studios in Germany, France, Portugal Marinha and UK, offer state of the art laser texture, from ultrafine to prominent geometric patterns. It can also process tools with weights of up to 20 tonnes. We also offer 5-axis LASERtex services worldwide with carefully selected partners.

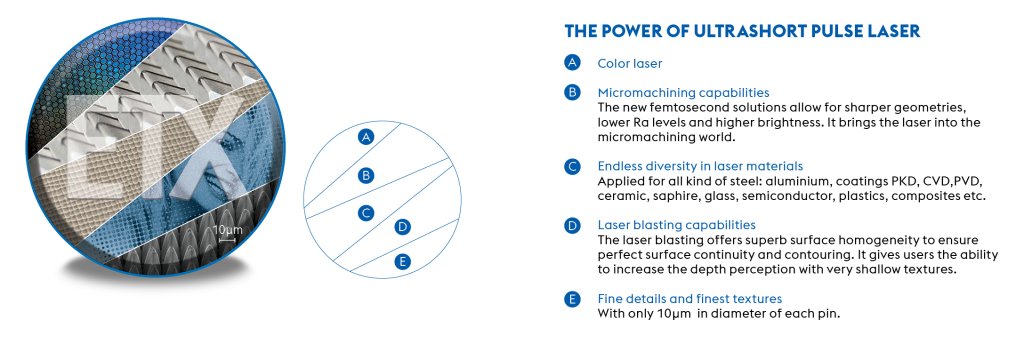

The innovative 5-axis LASERtex uses laser ablation where a laser beam removes layer by layer from the tool surface of a plastic injection die. This produces multi-layered surface laser texture, ranging from complex architectural or geometric patterns to textile, natural patterns and fine textures. This method is also suitable for manufacturing functional surfaces such as for light reflection, friction, aerodynamics, etc.

Features of LASERtex – a laser texture technoloy

- Fully digital process chain with high repeatability

- Unlimited freedom of design

- Direct lasering of 3D textures

- Suitable for steel, aluminium and with some restrictions – for electrode materials (copper, graphite, tungsten)

- Capability for ultrafine (<1µm) hybrid morphing textures with very fine details and enables precise surface lasering

- High Precision Quality Check by GOM/Zeiss Scanning System with the possibility of Reverse Engineering