CERAtex

Ceramic systems

SURFACE ENHANCING TECHNOLOGY

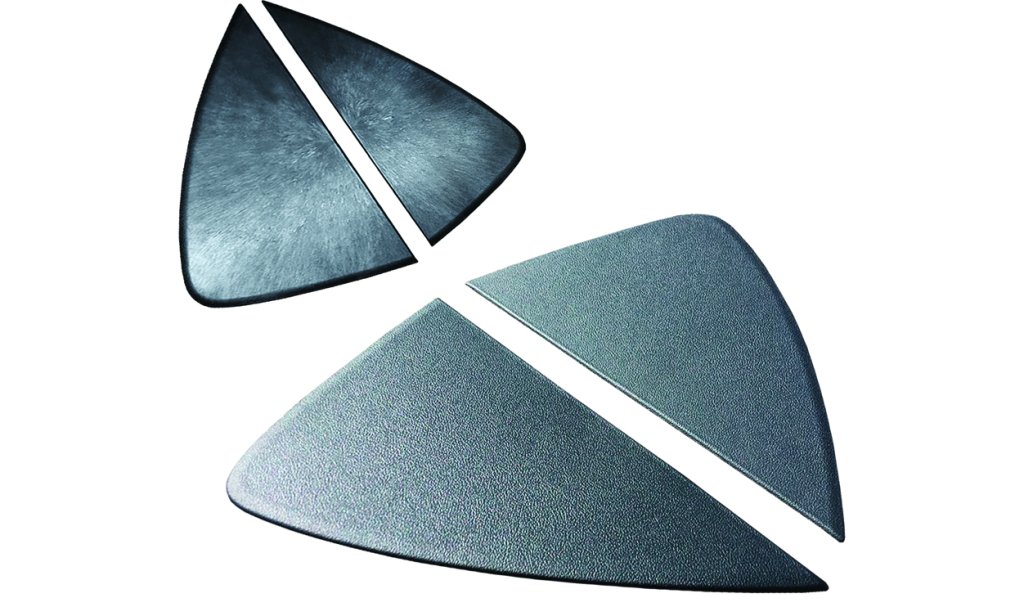

Greater design flexibility for plastic injection moulding: Eschmann Textures has an innovative 3D printing technology for pre-visualization CERAtex which enables different designs to be produced from the same tool.

In conventional production methods the tool determines how the structure looks. Things are different with this process: By applying a heat-resistant, almost wear-free ceramic coating to the tool surface, plastic components can be produced in a very wide range of different looks.

This provides you with a completely new level of flexibility that gives you an extra dimension of design creativity. CERAtex adds a ceramic coating to create the surface texture.

This 3D printing technology for pre-visualization enables users to enhance an almost infinite range of products by adding customized surface textures. This ceramic process facilitates true-to-original design reproduction at unbeatably short reproduction lead times. CERAtex can be removed at any time from the tool without leaving residues and be re-applied without the need for additional polishing, modified wall thicknesses or similar.

Features

- Ranges from one-off custom designs to small batches

- Physical foaming (MuCell)

- In-mould graining (IMG)

- Blow moulding

- Silicone moulding tools

- Pu foaming tools

- Plastic injection moulding (including polypropylene, Polyurethane etc.

“Innovative lightweight construction “meets design”

CERAfoam

CERAshibo

BREAKTROUGH FOR THERMOPLASTIC FOAM INJECTION

MOULDING, LIGHTWEIGHT & UNIQUE GRAIN DESIGN

The combination of ceramic coated surfaces and unique Femto laser texturing offers high end design for foamed parts – free of foam streaks and with high freedom in part construction.

BENEFITS FROM

• Lightweight

• Reduce energy/CO2

• Unique grain

• Sustainability

CERAMIC TOOL COATINGS

- All surfaces can be moulded 1:1 and transferred into the smallest detail to the tool geometry

- Can be removed from the tool and re-applied with a new texture.

- Heat and wear-resistant, it processed at temperature ranges of up to 200°C

- Ideal for all standard plastic mould steels and aluminium as well as for physical foaming (MuCell)