Overcoming Challenges: Maximizing Tool Steel Performance in Glass Fibre Injection Moulding 🔧

By Mr. Gaurav Sharma – Uddeholm Outside Sales Officer – West Region

Glass fibre injection moulding offers incredible opportunities for manufacturing robust and lightweight components. However, it also presents unique challenges when it comes to selecting and utilizing the right tool steel. Today, let’s delve into some common challenges and explore effective solutions to ensure optimal tool steel performance in glass fibre injection moulding applications.

🚩 Challenge 1: Abrasive Wear

Glass fibres are notorious for their abrasive nature, causing accelerated wear on tool steel surfaces. This leads to reduced tool life and compromised part quality.

💡 Solution: Select High-Wear Resistance Tool Steel

Opt for tool steels specifically engineered to withstand abrasive wear, such as D2 or M2. These steels possess exceptional hardness and toughness, ensuring prolonged tool life and maintaining part integrity.

🚩 Challenge 2: Part Sticking

Molten glass fibre composites tend to adhere to tool surfaces during the moulding process, leading to part sticking issues. This can hinder production efficiency and increase downtime for cleaning and maintenance.

💡 Solution: Implement High-Temperature Release Coatings

Apply high-temperature release coatings to the tool steel surfaces to prevent part sticking. These coatings create a protective barrier between the composite material and the tool surface, allowing for easy release of the finished parts.

By identifying these common challenges and implementing appropriate solutions, manufacturers can enhance tool steel performance in glass fibre injection moulding, leading to improved productivity, extended tool life, and superior part quality.

Uddeholm

Uddeholm

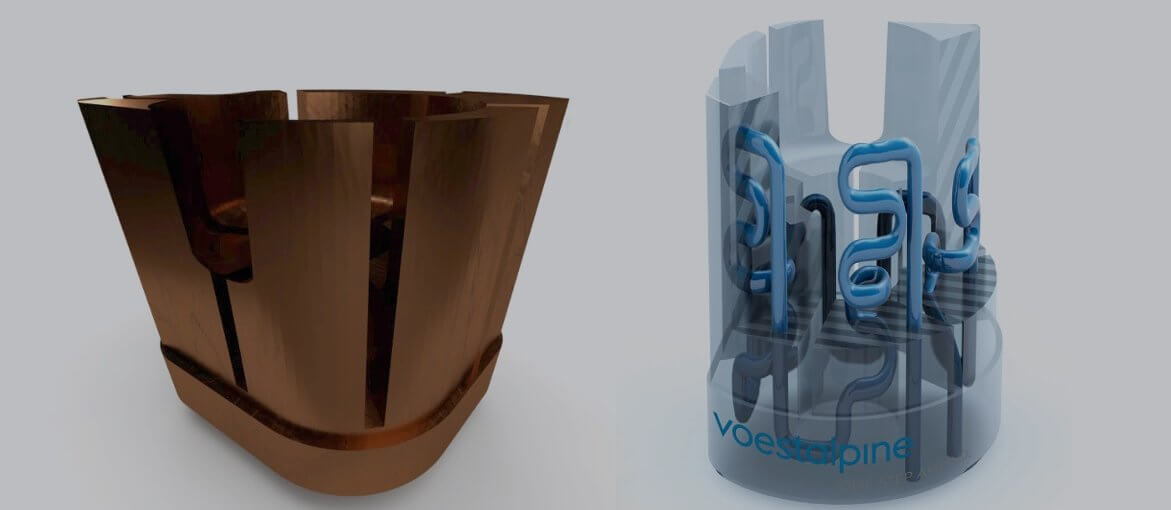

Uddeholm Plastic Mould Steel

Plastic compounds are frequently reinforced with glass fibres and mixed with halogen-free flame retardants. In addition, environmentally friendly materials like wood-plastic composites are replacing traditional plastics. These new materials are very aggresive on the tool steel, which in turn can lead to defects in the manufactured plastic parts. To avoid this, you need tool steel that is resistant to corrosion and abrasive wear.

Uddeholm Plastic Mould Application