Beryllium copper vs AM Conformal Cooling

IN THE SEARCH FOR ALTERNATIVE MATERIALS TO REPLACE HIGH THERMAL CONDUCTIVITY ALLOYS SUCH AS BERYLLIUM COPPER ALLOYS, TOOL DESIGNERS ARE TURNING TO ADDITIVE MANUFACTURING TO DELIVER THE MOULDING SOLUTIONS OF THE FUTURE.

PROBLEM

Tool designers put a great deal of effort into improving thermal management of the mould to reduce the cycle time. One popular way to achieve this is to use mould materials with high thermal conductivity. Materials such as aluminium and beryllium copper are a common replacements for traditional tool steels due to their increased thermal conductivity. Despite these materials proving to be an effective way to improve mould cycle times, they are not without their disadvantages. The durability of aluminium mould tools is significantly lower than their tool steel counterparts and as a result they are prone to premature wear and in many cases cracking due to their reduced hardness and strength. While beryllium copper can prove more effective than aluminium due to its improved mechanical properties, there are some disadvantages, that can lead to more complex and costly mould manufacturing and maintenance processes over the life of the tool, which need to be considered during the mould making.

IN SHORT

The adoption of additive manufacturing and the implementation of conformal cooling gives the tool designer greater control over the thermal characteristics of the insert. When implemented correctly AM can significantly improve tool productivity in a number of areas by reducing cycle time, by reducing the number of part defects per batch, and (if a high performance tool steel is used) extending tool life.

SOLUTION

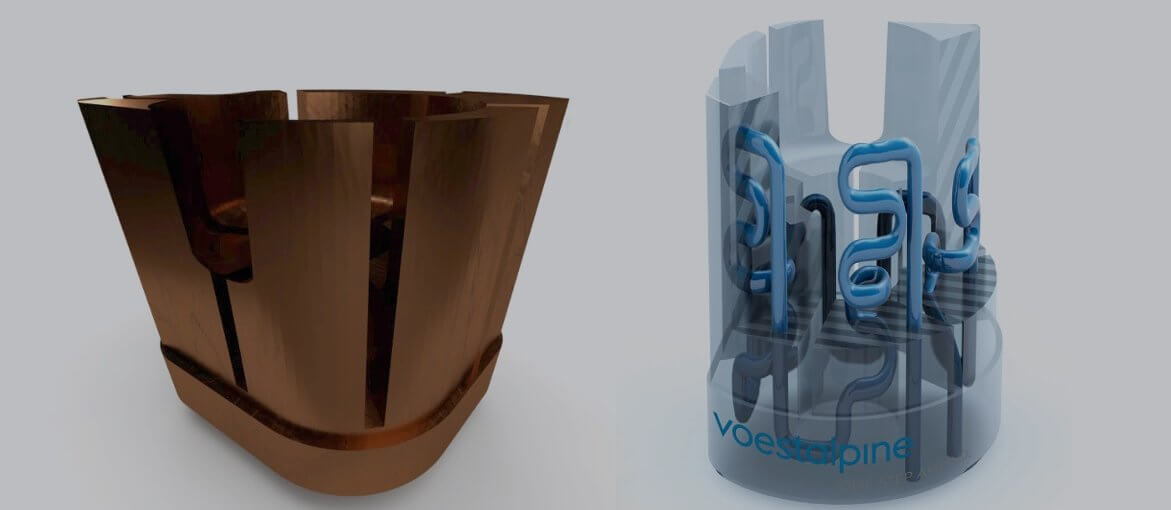

Replacing conventional beryllium copper inserts with 3D printed versions has proven an effective way to improve mould productivity. These inserts are produced by Selective Laser Melting and contain conformal cooling circuits designed specifically for each customers moulding process. Our inserts are printed using our own high performance tool steels (Uddeholm Corrax® for AM & BÖHLER M789 AMPO) to ensure the highest possible tool life. The ability to incorporate the conformal cooling system without changing the design of the insert, means the printed parts can enter production with minimum disruption to the end user

MATERIAL OF CHOICE

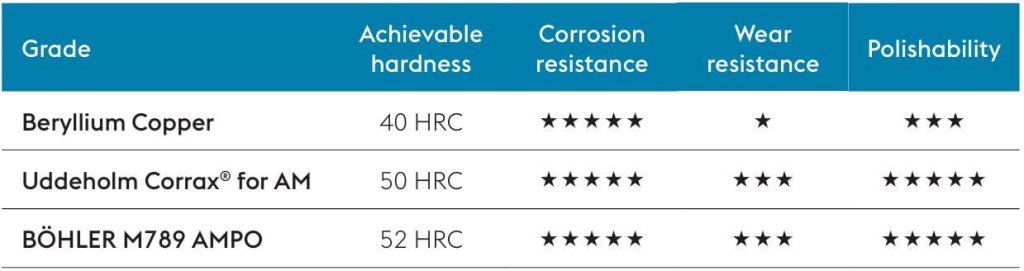

Uddeholm Corrax® for AM and BÖHLER M789 AMPO

- Designed for tooling applications, where corrosion resistance is needed

- Recommended hardness 45 to 52 HRC

- Good wear resistance

- Very good polishability

Blog Courtesy: voestalpine Additive Manufacturing