Heat Treatment

HOW TO INCREASE THE SERVICE LIFE OF YOUR TOOLS AND PRODUCTS?

In order to achieve higher material strength, better wear resistance and improved corrosion behavior of a tool or component, the heat treatment process is essential. It is our goal to provide you with a one-stop solution, from the initial stages of material selection to the final steps of post-treatment recommendations.

We offer a wide range of heat treatments through our worldwide distribution network. This allows us to optimize our products for your individual requirements.

Our offer for your specific applications

We currently offer heat treatment for tool steels such as, high alloy cold work steels, hot work steels, plastic mold steels, high speed steels, PM steels and special materials in 58 locations around the globe.

Our main services are:

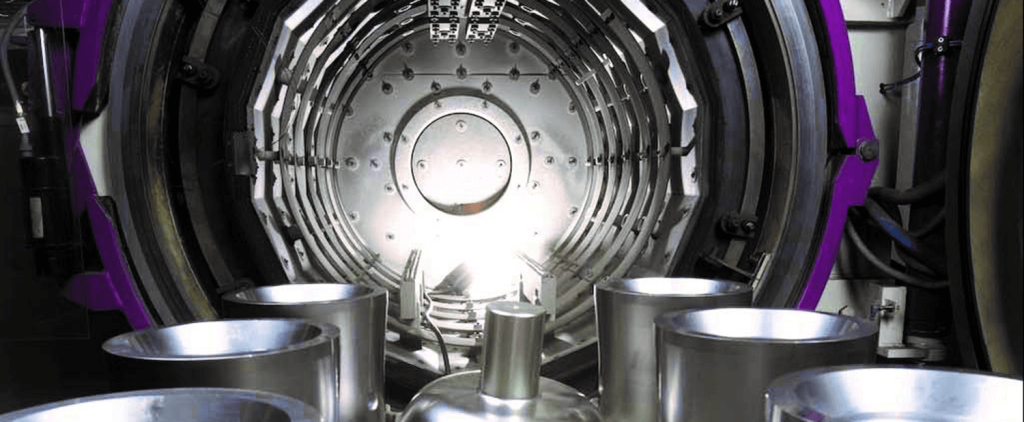

- Vacuum hardening

Our vacuum heat treatment process helps you achieve higher strength of material, better wear resistance and improved corrosive behavior of the components. - Gas Nitriding

In the gas nitriding process, nitrogen diffuses into the component surface and builds up the so-called connection layer on it. - Plasma Nitriding

This process enables partial nitriding to be carried out in the same way as in the gas nitriding process. Furthermore, in addition to the covering by means of paste, this process offers the possibility of mechanical covering. - Induction hardening (A, CZ, SK)

The induction hardening process is suitable for steels with a carbon content of at least 0.3%. Here the component surface is brought to hardening temperature by means of an inductor.

Further services we offer

- Oxidizing

- Oil Hardening

- Case Hardening

- Laser hardening and Laser Cladding (D + CN)

- Annealing, shot peening and sub-zero treatment of steels

Our engineers and metallurgists are constantly available to ensure that the heat treatment process is ideal for your company’s products.

Contact us for further information!

Please fill out this contact form for further information

Fields marked with * are mandatory.