Additive Manufacturing Solutions for Oil and Gas

We have successfully collaborated with Technology and Manufacturing divisions in the Oil and Gas industry in both development and delivery of high quality Additively Manufactured components. These components are part of a Rotary Steering System for directional drilling tools.

Other applications include: measuring while drilling (MWD), logging while drilling (LWD), completion tools, as well as wellhead and rig applications.

Benefits of AM Solutions for Oil and Gas:

- Shorter development lead time for prototyping

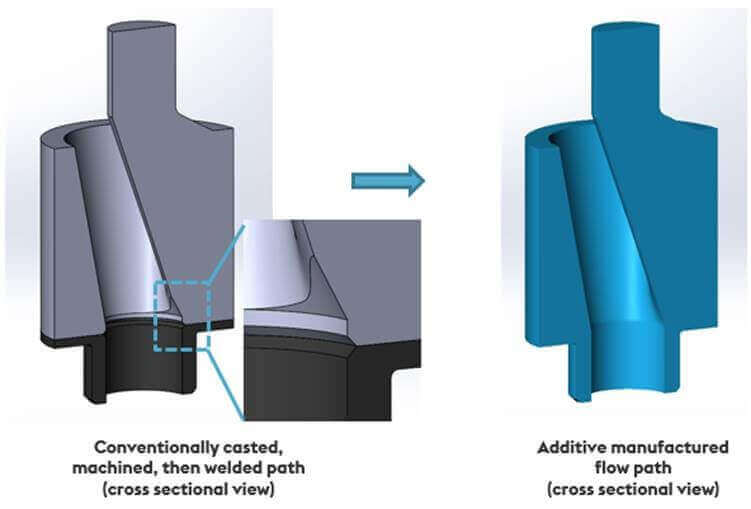

- Simplified manufacturing steps

- Stream-lined BOM & inventory

Complete Solution – From Powder to Finished Component

Qualified Materials for Oil and Gas:

- Stainless Steel: 316L, 17-4PH

- Nickel-Based Alloys: Inconel 625, 718 AMS & API

- 718 bending, fatigue properties meet API 150ksi standards

- Cobalt-Based Alloy: CoCr MP1 (Stellite 21)

Manufacturing Capabilities

- Printing: Powder Bed Fusion AM

- Thermal Processing: Heat Treatment, Hot Isostatic Pressing

- Machining: 5-Axis turn mill

- Coating: PVD

- Inspection: CMM and laser 3D scanner

Follow voestalpine Additive Manufacturing on LinkedIn