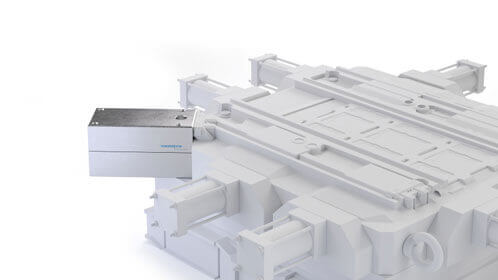

Produktkategorie: Engineered Products

voestalpine Chill Blocks

designed for pure performance

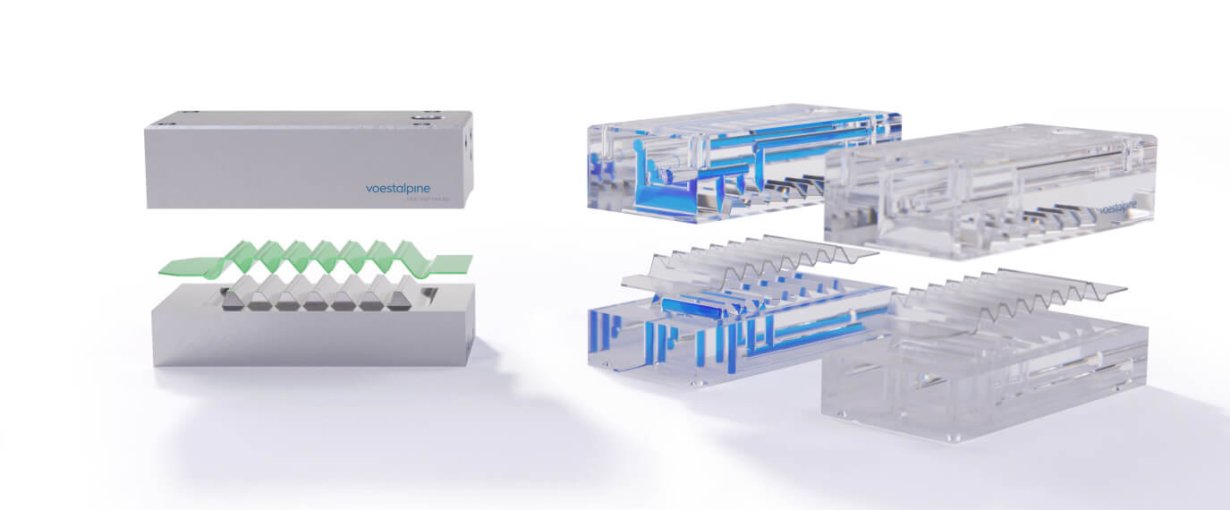

voestalpine Chill Blocks are made from premium materials by BÖHLER/Uddeholm and developed to combine the highest venting performance with maximum process reliability.

The patented wave design enables a gap size of up to 1.3 mm and therefore a significantly larger cross section for die evacuation compared to standard systems. As a result, venting-related defects such as gas porosity or short shots can be more reliably prevented. Furthermore, ejection forces are strongly reduced. This leads to an easy peel off and less bonding in the venting area.

Through these design and performance advantages, a more reliable filling process, less fluctuation in casting quality and less maintenance effort can be achieved.

Applications

Manufacturing Process

Conventional

Technical Data

Downloads

Please fill out this contact form for further information:

Fields marked with * are mandatory.