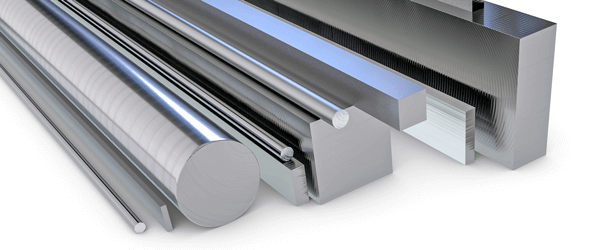

High Performance Materials

PERFORMANCE BEYOND EXPECTATION

voestalpine High Performance Metals focuses on technologically highly specialized product segments and is the global market leader in production and distribution of tool steel and other special steels.

We are fully integrated from production to sales and control the full supply chain. We are globally one of the the leading producers of: tool steel, high-speed steel, valve steel, engineering steel, powder metallurgy-produced steels, special steels and nickel-based alloys.

We also manufacture die-forged parts out of titanium alloys, nickel-based alloys and high, medium and low alloy steels.

TOOL STEEL

Tooling is one of the most challenging steel application. We are the world leader in this area. Among other things, our high quality tool steel is used for the production of high volume and high quality parts in various industries. Depending on the application, high tensile strength, toughness, working hardness, wear resistance and corrosion resistance are required.

A distinction is made between cold work, hot work and plastic mold steel. Cold work steel is required for the production of stamping, embossing and cutting tools. Hot work steel is used in tools for forging, die casting and extrusion. Molds and matrixes required for the production of plastic products are produced out of plastic mold steel.

Especially with our powder metallurgical and electro slag remelted steels we are pushing the boundaries with regards to the tool life and performance! Each of our market leading brands has a strong value proposition for our customers.

HIGH-SPEED STEEL

Used to produce highly demanding broaches, gear-cutting tools, industrial drills and milling cutters. Wear resistance, hot hardness and toughness that prevent the cutting edges from breaking loose are important properties of these types of steel.

With our wide portfolio of powder metallurgical produced high speed steels we can reach the most challenging requirements is particularly with regards to wear-resistance and corrosion-resistance. High-Speed Steel is also used for special solutions for the Automotive and Consumer Goods industry.

COPPER ALLOYS

Copper Alloys play an important role to improve the productivity especially for plastic injection molding and blow molding. They are also important for industries like Oil & Gas, Food Processing or the Aerospace Industry. With special alloying concepts a unique combination of thermal conductivity, toughness and hardness can be reached! Thereby hot spots can be eliminated in plastic injection molds.

ALUMINIUM ALLOYS

Aluminium Alloys play an important role in blow-forming, tools for small series and prototyping. Additionally, Deville offers Aluminum alloys for the aerospace and machine building industry.

NICKEL-BASED ALLOYS

voestalpine High Performance Metals Division’s produces and distributes Ni-base alloys like Alloy718, Alloy625, Alloy 925, Alloy90, Alloy X, etc. With our fully integrated supply chain we full fill the stringent specifications of our customers in the Automotive, Oil & Gas and Aerospace industry.

VALVE STEEL

Used in internal combustion engines. Valve steels are able to withstand higher temperatures, with good resistance to corrosive attacks of engine exhaust gases and also to thermal and mechanical shocks.

ENGINEERING STEEL

We offer a wide portfolio of engineering steels, which are used in various industrial applications like Automotive, Oil & Gas and Power Generation (for example in gearboxes for wind turbines and generator shafts).

SPECIAL STEELS

For components that must be particularly heat-resistant, tough and corrosion-resistant, which are primarily used in the aircraft industry, in automotive, engineering and energy technology (Oil & Gas industry), and also in medical technology.

TITANIUM PRODUCTS

We produce and distribute alloyed Titanium products like Grade 5 (Ti 64), Grade 23 (Ti 64 ELI), Ti 6242, etc. as well as CP Titanium (Grade 1-4) in the form of closed die forgings, sheets and plates or bars. We have long established partnerships to purchase the pre-material. With our processes we fulfill the most demanding specifications of our customers in the Aerospace, Chemical and Medical industry.