Products & Services Oil & Gas

Materials

- voestalpine BÖHLER Edelstahl (Bars, Billets, Wire, Open Die Forgings)

- voestalpine BÖHLER Bleche (Sheets & Plates)

- Villares Metals (Bars, Billets, Wire, Open Die Forgings)

- voestalpine Specialty Metals Europe (Central European distributor with value added services)

- voestalpine Specialty Metals (Oil & Gas distribution and value added services centers)

voestalpine BÖHLER Edelstahl

Long Products (bars, billets, wire, open die forgings)

Dimensions

| Cross sections of round billets – Surface ground to remove defects | |

|---|---|

or bright ground | 100 – 1200 mm (3.94 – 47.24″) |

with peeled surface | 100 – 425 mm (3.94 – 16.73″) |

with turned surface | 425 – 900 mm (16.73 – 35.43″) |

| Cross sections of square billets | |

|---|---|

Surface bright ground | 100 – 600mm (3.94 – 23.62″) |

| BAR rolled | ||

|---|---|---|

round | 12.5 – 150 mm (0.49 – 5.91″) | |

square | 15 – 130 mm (0.59 – 5.12″) | |

flat | width, mm (inch) | thickness, mm (inch) |

15 – 60 (0.59 – 2.36) | 5 – 41 (0.20 – 1.61) | |

60 – 200 (2.36 – 7.87) | 5 – 86 (0.20 – 3.39) | |

100 – 300 (3.94 – 11.81) | 15 – 80 (0.59 – 3.15) |

| ROLLED WIRE | |

|---|---|

rolled | dia. 5.0 – 13.5 mm (0.20 – 0.53″) |

drawn | dia. 1.0 – 12.0 mm (0.04 – 0.47″) |

| BAR forged | |

|---|---|

round | 110 – 1200mm (4.33 – 47.24″) |

square | 90 – 1200mm (3.54 – 47.24″) |

flat | width, mm (inch) | thickness, mm (inch) |

Ratio width / thickness maximum 10:1 |

| BAR pre-machined | |

|---|---|

IBO ECOMAX | 12.5 – 425 mm (0.49 – 16.73″) |

BRIGHT STEEL | |

ECOBLANK | peeled and polished |

ECOFINISH | band ground |

BRIGHT BAR | ground and polished |

| Open die forgings |

|---|

premachined or ready machined according to customer requirements, up to 45 tons. |

Duplex and super-duplex grades

| Brand | UNS | ASTM | Melting route | Others | Industry Specifications | Products and Size Range |

|---|---|---|---|---|---|---|

BÖHLER A903 | 1.4462 | F51 | Airmelted | X2CrNiMoN 22-5-3 | Norsok-M-650 | Round bar: 12.5 – 304.8 mm (0.5 – 12″) |

BÖHLER A911SA | 1.4501 | F55 | Airmelted | X2CrNiMoCuWN 25-7-4 | Norsok-M-650 | Round bar: 12.5 – 304.8 mm (0.5 – 12″) |

BÖHLER A913 | 1.4410 | F53 | Airmelted | X2CrNiMoN 25-7-4 | Norsok-M-650 | Round bar: 12.5 – 304.8 mm (0.5 – 12″) |

BÖHLER A930 | 1.4507 | F61 | Airmelted | X2CrNiMoCuN 25-6-3 | DIN EN 10088-3 | Round bar: 12.5 – 304.8 mm (0.5 – 12″) |

Austentics

| Brand | Market Grade | UNS | ASTM | Melting Route | Others | Industry Specifications | Products and Size Range |

|---|---|---|---|---|---|---|---|

BÖHLER A220 | 1.4435 | 316LUG | Airmelted + ESR | X2CrNiMo 18-14-3 | STAC 18005 | Round bar: 12.5 – 600 mm | |

BÖHLER A405 | 1.4466 | 310MoLN | Airmelted + ESR | X2CrNiMoN 25-22-2 | STAC 18005 | Round bar: 12.5 – 600 mm | |

BÖHLER A959 | Alloy 28 | 1.4463 | Airmelted | DIN EN 10088-3 | Round bar: 12.5 – 203.2 mm | ||

BÖHLER A965SA | 1.4547 | F44 | Airmelted | X2CrNiMoCuN | Norsok-M-650 (MDS R17, size mill request necessary) | Round bar: 12.5 – 228.6 mm | |

BÖHLER A970 | 1.4529 | Airmelted | X2CrNiMoCuN | DIN EN 10088-3 | Round bar: 12.5 – 228.6 mm | ||

BÖHLER P511 | XM-19 | S20910 | Airmelted | X2CrNiMoCuNbN 21-13-3 | ASTM A276, A479, A182 | Round bar: 12.5 – 304.8 mm | |

BÖHLER P513 | S21800 | S21800 | Airmelted | ASTM A276, A479, A193, A194, | Round bar: 12.5 – 304.8 mm | ||

BÖHLER T200 | 660A286 | 1.4980 | Airmelted + ESR | X5NiCrTi 26-15 | VdTÜV 435 | Round bar: 12.5 – 254 mm (0.5 – 10″) |

Nickel Base Alloys

| Brand | Market Grade | UNS | ASTM | Melting route | Others | Industry Specifications | Products and Size Range |

|---|---|---|---|---|---|---|---|

BÖHLER L625 | Alloy 625 | 2.4856 | VIM + ESR | NiCr22Mo9Nb | AMS 5666 | Round bar: 12.5 – 254 mm (0.5 – 10″) | |

BÖHLER L725 | Alloy 725 | N07725 | VIM + VAR | API 6A CRA | Round bar: 12.5 – 203.2 mm (0.5 – 8″) | ||

BÖHLER L825 | Alloy 825 | N08825 | Airmelted | ASTM B425 | Round bar: 12.5 – 304.8 mm (0.5 – 12″) | ||

BÖHLER L750 | Alloy X750 | N07750 | VIM + VAR | ASTM B637 | Wire: 5 – 15 mm (0.2 – 0.6“) | ||

BÖHLER L925 | Alloy 925 | N09925 | VIM + VAR | NiCr21TiCuMo | API 6A CRA | Round bar: 12.5 – 355.6 mm (0.5 – 14″) | |

BÖHLER L718API | Alloy 718API | N07718 | VIM + VAR | NiCR19NbMo | API 6A CRA | Round bar: 12.5 – 355.6 mm (0.5 – 14″) | |

BÖHLER L718AMS | Alloy 718AMS | 2.4668 | VIM + VAR | NiCR19NbMo | AMS 5662 | Round bar: 12.5 – 203.2 mm (0.5 – 8″) | |

BÖHLER L059 | Alloy 59 | 2.4605 | VIM + ESR | NiCR23Mo16AI | ASTM B574 | Round bar: 12.5 – 203.2 mm (0.5 – 8″) | |

BÖHLER L276 | Alloy 276 | 2.4819 | VIM + ESR | NiCR21Mo14W | VdTÜV 400 (max. 360 mm/~14″) | Round bar: 12.5 – 355.6 mm (0.5 – 14“) | |

BÖHLER L004 | Alloy 004 | 2.4610 | VIM + ESR | NiMo16Cr15W | VdTÜV 424 (max. 360 mm/~14″) | Round bar: 12.5 – 355.6 mm (0.5 – 14“) | |

BÖHLER L022 | Alloy 022 | 2.4602 | VIM + ESR | NiMo16Cr16Ti | VdTÜV 479 (max. 360 mm/~14″) | Round bar: 12.5 – 355.6 mm (0.5 – 14“) | |

BÖHLER L035 | R30035 | R30035 | VIM + VAR | AMS 5844 | Wire: 5 – 15 mm (0.2 – 0.6“) |

Heat Treatable Steels

| Brand | Market Grade | UNS | ASTM | Melting route | Others | Industry Specifications | Products and Size Range |

|---|---|---|---|---|---|---|---|

BÖHLER N400 | F6NM | 1.4313 | F6NM | Airmelted | X4CrNi 13 4 | DIN EN 10088-3 | Round bar: 12.5 – 1,040 mm (0.5 – 40.94″) |

BÖHLER N404 | 1.4418 | Airmelted | X4CrNiMo 16 5 | DIN EN 10088-3 | Round bar: 12.5 – 500 mm (0.5 – 19.68″) |

PH Grades

| Brand | Market Grade | UNS | ASTM | Melting Route | Others | Industry Specifications | Products and Size Range |

|---|---|---|---|---|---|---|---|

BÖHLER N700SA | 17-4 PH | 1.4542 | 630 | Airmelted | X5CrNiCuNb 17 4 | DIN EN 1008-3 | Round bar: 12.5 – 203.2 mm (0.5 – 8″) |

BÖHLER N701 | 15-5 PH | 1.4545 | XM 12 | Airmelted +VAR | X5CrNiCuNb 15 5 | ASTM A564 | Round bar: 12.5 – 203.2 mm (0.5 – 8″) |

voestalpine BÖHLER Bleche

Flat products (sheets & plates):

Dimensions

| Dimensions hot rolled | Surface finish |

|---|---|

Width max. 2,000 mm | As rolled |

Length max. 7,000 mm | Shot blasted |

Thickness 2.0 mm up to 90.0 mm | Pickled |

Weight max 2,000 kg | Ground |

Milled |

| Dimensions cold rolled | Minimum order quantities |

|---|---|

Width max. 1,250 mm | Standard alloys (output of one slab)

|

Length max. 5,000 mm | Steel 800 – 3,000 kg |

Thickness 1,0 mm up to 6.0 mm | Ni-base-alloys 800 – 2,200 kg |

Titanium 600 – 1,100 kg | |

Edge Finish | |

Shear cut | Special alloys (output of one melt) |

Laser cut | VID 6-8

|

Cold sawn | EAF-VOD 25 – 35 to |

Plasma cut | VIM 4 alt. 10 to (Ni-base-alloys) |

Water jet cut |

Corrosion Resistant Alloys

| Type of Alloy | Brand | PREN | Common name | DIN / EN | UNS | Standards | Main Applications |

|---|---|---|---|---|---|---|---|

Superduplex | BÖHLER A9111SA

| 41 | 1.4501 | S32760 |

|

| |

Super Austenite | BÖHLER A610 | 1.4361 | S30600 |

| Nitric Acid Production, Storage | ||

Super Austenite | BÖHLER A611 | S30601 |

| Sulfuric Acid Production, Storage | |||

Super Austenite | BÖHLER A614 | ~1.4469 | S32615 |

| Sulfuric Acid Production, Storage | ||

Super Austenite | BÖHLER A657 | 1.4335 |

|

| Nitric Acid Production, Storage | ||

Super Austenite | BÖHLER A965A | 43 | 6-Mo | 1.4547 | S31254 |

|

|

Super Austenite | BÖHLER A952 | Alloy 31 | 1.4562 | N08031 |

| Chemical and Petrochemical Industry | |

Super Austenite | BÖHLER A970 | 42 | 1.4529 |

| ASTM B625 | Offshore Industry | |

Nickel-Base | BÖHLER L022 | Alloy C22 | 2.4602 | N06022 |

| Chemical Industry, Pharmacy | |

Nickel-Base | BÖHLER L276 | Alloy C276 | 2.4819 | N10276 |

| Chemical Industry, Pharmacy | |

Nickel-Base | BÖHLER L625 | Alloy 625 | 2.4856 | N06625 |

| Offshore Industry | |

Nickel-Base | BÖHLER L004 | Alloy C4 | 2.4610 | N06455 |

| Chemical Industry | |

Nickel-Base | BÖHLER L825 | Alloy 825 | 2.4858 | N08825 |

| Chemical Industry | |

Nickel-Base | BÖHLER L059 | Alloy 59 | 2.4605 | N06059 |

| Chemical Industry, Pharmacy | |

Nickel-Copper | BÖHLER L400 | Alloy 400 | 2.4360 | N04400 |

| Chemical Industry |

Heat Resistant Alloys

| Type of Alloy | Brand | Common name | DIN / EN | UNS | Standards | Main Application |

|---|---|---|---|---|---|---|

Austenite | BÖHLER H500 | Alloy 800/800H/800HT | 1.4876 |

|

| Industrial Furnaces |

Austenite | BÖHLER T200 | Alloy 286 |

| S66286 | EN 10302 | Turbines |

Nickel-Base | BÖHLER L617 | Alloy 617 | 2.4663 | N06617 |

|

|

Special Alloys and Titanium

| Properties | Type of Alloy | Brand | PREN | Common name | DIN / EN | UNS | Standards | Main Applications |

|---|---|---|---|---|---|---|---|---|

Machinability | Austenite | BÖHLER A506 | AISI 303 | 1.4305 | S30300 |

|

| |

Nonmagnetic | Austenite | BÖHLER P512 | 43 | 1.4565 | S34565 |

|

|

| Type of Alloy | Brand | Common name | UNS | Material Number | Standards | Main Applications |

|---|---|---|---|---|---|---|

Commercially Pure Titanium | BÖHLER L511 | Grade 1 | R50250 | 3.7025 |

| Industry |

Commercially Pure Titanium | BÖHLER L511 | Grade 2 | R50400 | 3.7035 |

| Industry |

Commercially Pure Titanium | BÖHLER L513 | Grade 2 | R50550 | 3.7055 | ASTM B625 | Industry |

Commercially Pure Titanium | BÖHLER L514 | Grade 4 | R50700 | 3.7065 |

|

|

Alloyed Titanium | BÖHLER L531EB | Grade 5 | R56400 | 3.7165 | ASTM B625 | Industry |

Alloyed Titanium | BÖHLER L519 | Grade 9 | R56620 | 3.7194 | ASTM B625 | Industry |

Villares Metals

Forged Parts Restraints

| Product | Dimensions and Weight | (Rough Machined) | Limitations |

|---|---|---|---|

Round Bars | D = 127 to 1.420 mm | D <= 240 => +2/-0 D>= 240 => +3/-0 L => +10/-0 | Bars with diameters larger than 650 mm |

Square Bars | T = 130 to 1.250 mm | T => +3/-0 L => +10/-0 | Bars with thickness larger than 650 mm and |

Flat Bars | T = 130 to 1.250 mm | T => +3/-0 W => +3/-0 L => +10/-0 | Bars with thickness or width larger than 650 |

Hollow Bars | D = 203 to 1.300 mm | D <= 240 => +2/-0 D>= 240 => +3/-0 Di => +/-1,5 L => +10/-0 | The dimension of holes depends on the |

Disks (H<D) | D = 450 to 2.340 mm | D => +3/-0 H => +10/-0 | Parts with diameter from 900 to 2,340mm |

Rings (H<D) | D = 450 to 3.000 mm | D => +3/-0 Di => +0/-3 H => +10/-0 | Sum of inner diamter and thickness must be |

Sleeves (L>D) | D = 500 to 2.600 mm | D => +3/-0 Di => +0/-3 L => +10/-0 | Sum of inner diameter plus thickness must |

Solid Blanks | D = 127 to 1.600 mm | D => +3/-0 L => +10/-0 | Parts with diameter larger than 650mm and |

Flanged Shafts | D = 400 to 1.600 mm | D => +3/-0 L => +10/-0 | Parts with diameter larger than 650mm and |

Hollow Blanks | D = 127 to 1.600 mm | D => +3/-0 Di => +/-1,5 H => +10/-0 | Sum of inner diameter and thickness must |

Engineering Steel

| Product | ASTM | UNSA | INSI | Others |

|---|---|---|---|---|

VM40 | ASMT A332 (4340) | G43400 | 4340 | SAE 4340/ AMS 6414 |

F11 | ASTM A182 GRADE F11 (MOD.) | K11597 K11572 | ASME SA387 Gr. 11 | |

F22 | ASTM A182 GRADE F22 (MOD.) |

K21590 | ASME SA387 Gr. 22 | |

VB30 | ASTM A322 (8630) ASTM A29 (8630) | G86300 | 8630 | SAE 8630 |

VL30 | ASTM A322 (4130) | G41300 | 4130 | SAE 4130 |

VL40

| ASTM A322 (4140) ASTM A646 (4140) |

G41400 |

4140 |

AMS 6349 |

VM30 | ASTM A322 (4330) ASTM A29 | K23080 | 4330 | EN 30B / AMS 6411 |

Specialty Alloys

| Product | ASTM | UNSD | IN / Wnr. |

|---|---|---|---|

VRC625 | ASTM B446 | UNS N06625 | DIN 17744 Wnr. 2.4856 |

VATX750 | ASTM B637 | N07750 | Wnr. 2.4669 |

VATX286A | ASTM A660 | Wnr. 1.4980 | |

VAT718A | ASTM B637 | N07718 | Wnr. 2.4668 |

VAT800HT | ASTM B408 | N08811 | Wnr. 1.4876 1.4959 |

VRC400 | ASTM B164 B564 | N04400W | Wnr. 2.4360 |

Precipitation Hardening Steels

| Product | ASTM | DIN / Wnr. | Others |

|---|---|---|---|

V630 | ASTM A564 (630) 17-4 PH |

1.4542 | AMS 5643 AMS 5622 |

N4534 | ASTM A564 (XM-13) PH 13-8 Mo |

1.4534 |

AMS 5629 |

Duplex and Super Duplex Stainless Steels

| Product | ASTM | UNS | DIN / Wnr. |

|---|---|---|---|

N4460 | ASTM A182 GR F50 / ASTM A276 |

UNS S32900 | DIN X3CrNiMoNbN Wnr. 1.4460 |

N4462 | ASTM A 182 Gr. F51 / ASTM A276 |

UNS S31803 | DIN 2CrNiMoN Wnr. 1.4462 |

VF53 | ASTM A182 Gr F53 / ASTM A276 |

UNS S32750 | DIN X2CrNiMoN 25-7-4 Wnr. 1.4410 |

N4501 | ASTM A182 Gr F55 / ASTM A276 |

UNS S32760 | DIN 2CrNiMoCuWN25-7-4 Wnr. 1.4501 |

N4507 | ASTM A182 Gr F61 / ASTM A276 |

UNS S32550 | DIN X2CrNiMoCuN25-6-3 Wnr. 1.4507 |

Martensic Stainless Steels

| Product | ASTM | NS | AISI | DIN / Wnr. | Others |

|---|---|---|---|---|---|

N4313 | ASMT A182 Gr F6NM | S41500 | DIN X3CrNiMo13-4 Wnr. 1.4313 | ||

VC140 | ASTM A276 (410) ASTM A182 / Gr F6a | S41o00 | 410 | DIN X12Cr13 Wnr. 1.4006 | NBR 5601 SAE 51410 |

VC150 | ASMT A276 (420) | S42000 | 420 | DIN X20Cr13 Wnr. 1.4021 | NBR 5601 Type 420 |

V416 | ASMT A582 (416) | S41600 | 416 | DIN X12CrS13 Wnr. 1.4005 | NBR 5601 AMS 5610L Type II |

Maraging Steels

| Product | ASTMU | NS | AMSM | IL |

|---|---|---|---|---|

VART250 (MARAGING 250) | ASTM A579 GR 72 | UNS K92890 | AMS 6512 | MIL-S-46850D |

VART300 (MARAGING 300) | ASTM A579 GR 73 | UNS K93120 | AMS 6514 | MIL-S-46850D |

VXM19 | ASTM A276/ ASTM A479 GR XM19 | S20910 | AMS 6514 | MIL-S-46850D |

Austentic Stainless Steels

| Product | ASTM | UNS | AISI | DIN / Wnr. |

|---|---|---|---|---|

V304UF | ASMT A182 / Gr F304 ASTM A276 | S304003 | 04 | DIN X5CrNi18-10 Wnr. 1.4302 |

V304XLUF | ASMT A182 / Gr F304L ASTM A276 | S30403 | 304L | DIN X2CrNi18-9 Wnr. 1.4307 |

V316UF | ASMT A182 / Gr F316 ASTM A276 | S316003 | 16 | DIN X5CrNiMo17-12-2 Wnr. 1.4401 |

V316XLUF | ASMT A182 / Gr F316L ASTM A276 | S31600 | 316L | DIN X2CrNiMo17-12-2 Wnr. 1.4404 |

V317L | ASMT A182 / Gr F317L ASTM A276 | S31703 | 317L | DIN X3CrNiMo18-12-3 Wnr. 1.4449 |

V321 | ASMT A182 / Gr F321 ASTM A276 | S321003 | 21 | DIN X5CrNiTi18-10 Wnr. 1.4541 |

V347SI | ASTM A182 / Gr F347 ASTM A276 | S347003 | 47 | DIN X5CrNiTi18-10 Wnr. 1.4543 |

voestalpine Specialty Metals Europe

Products

- Forged Parts

- Seemless rolled rings

- Stepped Shafts

- Parts according to drawing

- Bars

- Sheets, Plates, Strips and Waterjet cut parts

- Tubes

- Special products

Services

- Heat Treatment

- Hot work hardening

- Surface Treatment

- Sawing

- Waterjet Cutting

- Cold Drawing

- Material Testing

Nickel Alloys

| Material Number | Alloy | UNS |

|---|---|---|

2.4068 | Nickel 201 | N02201 |

2.4360 | Alloy 400 | N04400 |

2.4375 | Alloy K500 | N05500 |

2.4602 | Alloy C22 | N06022 |

2.4605 | Alloy 59 | N06059 |

2.4610 | Alloy C-4 | N06455 |

2.4633 | Alloy 602 CA | N06025 |

2.4634 | Alloy 105 | N132021 |

2.4650 | Alloy C-263 | N07263 |

2.4660 | Alloy 20 | N08020 |

2.4663 | Alloy 617 | N06617 |

2.4665 | Alloy X | N06002 |

2.4668 | Alloy 718 | N07718 |

2.4669 | Alloy X-750 | N07750 |

2.4816 | Alloy 600 | N06600 |

2.4819 | Alloy C-276 | N10276 |

2.4851 | Alloy 601 | N06601 |

2.4856 | Alloy 625 | N06625 |

2.4858 | Alloy 825 | N08825 |

2.4878 | Alloy 101 | |

2.4951 / 2.4630 | Alloy 75 | N06075 |

2.4952 / 2.4631 | Alloy 80A | N07080 |

2.4964 | Alloy L-605 | R30605 |

2.4969 / 2.4632 | Alloy 90 | N07090 |

2.4973 | Alloy R-41 | N07041 |

2.4975 / 2.4662 | Alloy 901 | N09901 |

Alloy 725 | N07225 | |

2.4852 | Alloy 925 | N09925 |

Titanium and Titanium Alloys

| Material Number | Alloy | UNS |

|---|---|---|

3.7025 / 3.7024 | Ti Grade 1 | R50250 |

3.7025 / 3.7024 | Ti Grade 2 | R50400 |

3.7055 | Ti Grade 3 | R50550 |

3.7065 / 3.7064 | Ti Grade 4 | R50700 |

3.7105 | Ti Grade 12 | R53400 |

3.7145 / 3.7144 | Ti-6-2-4-2 | R54620 |

3.7165 / 3.7164 | Ti Grade 5 | R56400 |

3.7175 / 3.7174 | Ti-6-6-2 | R56620 |

3.7185 / 3.7184 | Ti-4-4-2 | |

3.7195 / 3.7194 | Ti Grade 9 | R56320 |

3.7235 | Ti Grade 7 | R52400 |

Special Steel

| Material Number | Alloy | UNS |

|---|---|---|

1.3912 | Alloy 36 | K93600 |

1.3917 | Alloy 42 | K94100 |

1.3964 | Alloys 50 | S20910 |

1.3974 | ||

1.3981 | Alloy K | K94610 |

1.4313 | F6NM | S41500 |

1.4429 ESU | 316LN ESR | S31653 |

1.4529 | Alloy 926 | N08904 |

1.4534 | PH 13-8Mo | S17400 |

1.4539 | Alloy 904L | N08904 |

1.4542 / 1.4548 | 17-4 PH | S17400 |

1.4545 | 15-5 PH | S15500 |

1.4550 / 1.4546 | Alloy 347 | S34700 |

1.4562 | Alloy 31 | N08031 |

1.4568 | 17-7 PH | S17700 |

1.4876 | Alloy 800 | N08810 |

1.4939 | Jethete | S64152 |

1.4958 | Alloy 800H | N08810 |

1.4959 | Alloy 800HT | N08811 |

1.4980 / 1.4944 | A286 | S66286 |

1.4986 | ||

1.6358 / 1.6354 | Maraging 300 | K93120 |

Other

| Material Number | Alloy | UNS |

|---|---|---|

Zr 702 | R60702 | |

Zr 705 | R60705 | |

Molybdenum | ||

Tantulum | ||

Tungsten |

voestalpine Specialty Metals

Services

- Stocking

- Deep hole boring / drilling

- Cutting

- Finish machining

- Heat Treatment

- Threading

- Mechanical testing / NDT

- Forged components

- Milling & turning

- Additive Manufacturing

- Repair and hard facing

Nickel Alloys

| Product | Market Grade | UNS | Bar | Billet | Wire | Sheet | Plate | Forgings | AM Powder |

|---|---|---|---|---|---|---|---|---|---|

L359 | Alloy 59 | N06059 | x | ||||||

Monel 400 | Alloy 400 | N04400 | x | ||||||

Monel K500 | Alloy K500 | N05500 | x | ||||||

L331/L625 | Alloy 625 | N06625 | x | x | x | x | x | x | x |

L718 | Alloy 718 AMS | N07718 | x | x | x | x | x | x | x |

L718API | Alloy 718 API | N07718 | x | x | x | x | x | x | |

L725 | Alloy 725 | N07725 | x | x | x | x | |||

L314 | Alloy 825 | N08825 | x | x | x | x | x | x | |

L090 | Alloy 90 | N07090 | x | x | x | ||||

L901 | Alloy 901 | N09901 | x | x | x | x | |||

L925 | Alloy 925 | N09925 | x | x | x | x | |||

L022 | Alloy C22 | N06022 | x | x | x | ||||

L276 | Alloy C276 | N10276 | x | x | x | ||||

L004 | Alloy C4 | N06455 | x | x | x | ||||

L003 | Alloy G3 | N06985 | x | ||||||

L750 | Alloy X750 | N07750 | x | ||||||

L303 | Waspaloy | N07001 | x | x | x |

Ferritic, Martensitic & PH Steels

| Product | Market Grade | UNS | Bar | Billet | Wire | Sheet | Plate | Forgings | AM Powder |

|---|---|---|---|---|---|---|---|---|---|

N400 | F6NM | S41500 | x | x | x | x | |||

N404 | DIN 1.4418 | SS2387 | x | ||||||

N700 | 17-4 PH | S17400 | x | x | x | x | |||

N701 | 15-5 PH | S15500 | x | x | x | ||||

13CR (420M) | S42000 | x | |||||||

Super 13CR | S41427 | x |

Duplex & Super Duplex Steels

| Product | Market Grade | UNS | Bar | Billet | Wire | Sheet | Plate | Forgings | AM Powder |

|---|---|---|---|---|---|---|---|---|---|

A903 | F51 Duplex | S31803 | x | x | x | x | x | x | |

A913 | F53 Duplex | S32750 | x | x | x | ||||

A911SA | F55 Duplex | S32760 | x | x | x | x | x | x |

Austenitic Steels

| Product | Market Grade | UNS | Bar | Billet | Wire | Sheet | Plate | Forgings | AM Powder |

|---|---|---|---|---|---|---|---|---|---|

A200 | 316/316 L | S31600/S31603 | x | ||||||

A965SA | F44 6Mo

| S31254 | x | x | x | x | |||

T200 | A286 | S66286 | x | x | x | ||||

P511 | Nitronic 50 | S20910 | x | x | x | ||||

P513 | Nitronic 60 | S21800 | x | x | x |

Engineering Steels

| Product | Market Grade | UNS | Bar | Billet | Wire | Sheet | Plate | Forgings | AM Powder |

|---|---|---|---|---|---|---|---|---|---|

F22 | K21590 | x | x | x | |||||

4130 | G41300 | x | x | x | |||||

4140 | G41300 | x | x | x | |||||

4145 | G41300 | x | x | x | |||||

4330V Mod. | K23080 | x | x | x | |||||

8630 Mod. | G86300 | x | x | x | |||||

9CR/1MO | K90941 | x | x | x | |||||

L314 | 4330V Mod. | K23080 | x | x | x | ||||

L090 | Alloy 90 | N07090 | x | x | x | ||||

L925 | Alloy 925 | N09925 | x | x | x | x | |||

L022 | Alloy C22 | N06022 | x | x | x | ||||

L276 | Alloy C276 | N10276 | x | x | x | ||||

L004 | Alloy C4 | N06455 | x | x | x | ||||

L003 | Alloy G3 | N06985 | x |

Shapes

We offer our materials in a wide range of shapes in various dimensions.

Services

We have our own sales and service network at around 140 locations in all industrialized regions of the world. The importance of this aspect is also demonstrated by the fact that about 40% of all division employees work in sales and service.

Additive Manufacturing

Additive manufacturing (AM), also known as “3D printing,” enables production with shorter lead times, at lower weight, and for shapes that were not previously feasible.

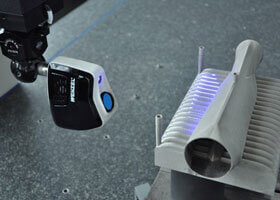

PVD & CVD Coating

With the acquisition of Eifeler, we are one of the leading suppliers of PVD (and CVD) coatings. Discover our wide range of coating systems here.

Heat treatment

We offer a wide range of Heat Treatments through our worldwide distribution network. This allows us to optimize our products for your specific applications.

Machining & Cutting Services

We aim to provide the best possible availability and short delivery times. This is achieved through machining services offered through our worldwide distribution network.

Warehousing

With our range of warehousing technology solutions, we meet the highest customer requirements, cover the entire value chain and guarantee the best quality standards.