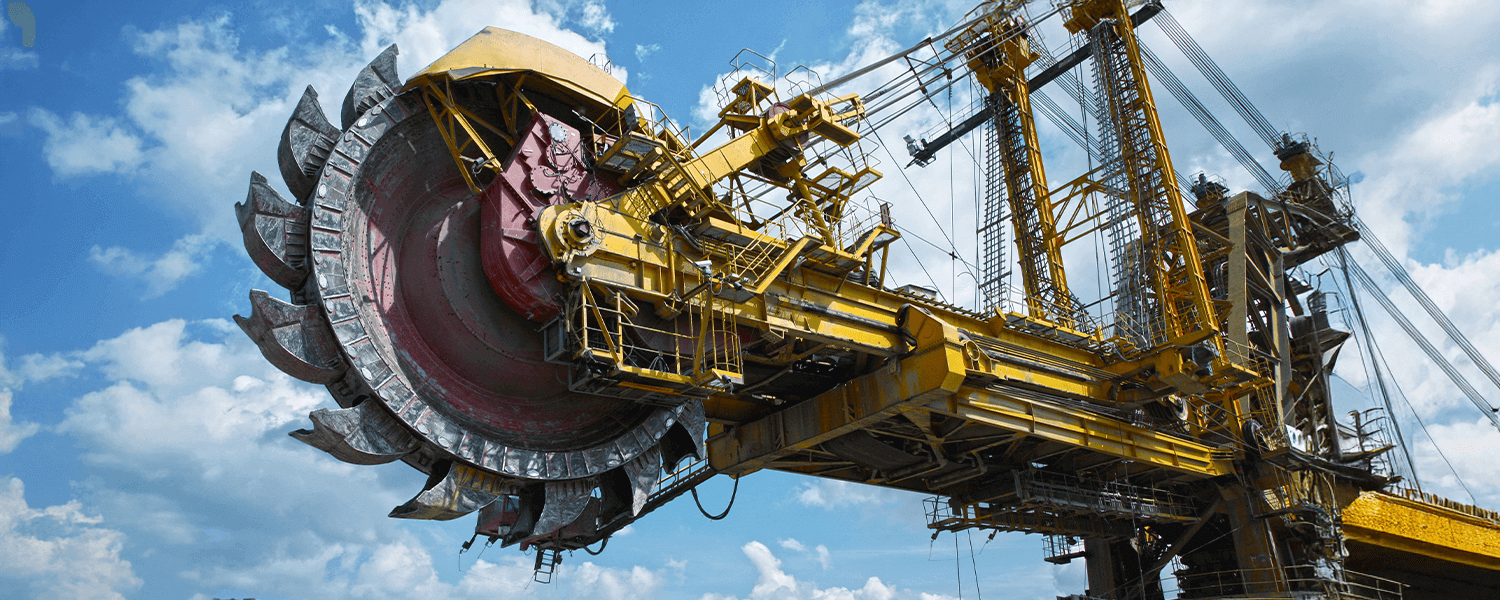

Mining

Increase Asset Performance with voestalpine Tool Steels

The mining industry is one of the most demanding industry sectors when is comes to component wear and abrasion damage. Traditionally, many of the parts produced for this sector rely on standard high tensile steel grades, but what if there was another way?

The adoption of voestalpine high performance tool steels in the mining sector has been proven to be successful across a wide range of applications from drill clamps to slurry pump valves. The resulting performance increase – in many cases increasing the service life of a component by a factor of 10 – over traditional high tensile or quench and tempered grades, means tool steels can prove to be an extremely cost effective solution in many applications.

Premium tool steels have many of the characteristics found desirable in the mining sector, these include:

- Wear Resistance

- Toughness

- Ductility

- Chipping Resistance

- High Hardness

Designed to Perform

Hardness, wear resistance, toughness, compressive strength and fatigue strength are typically achieved by alloying Carbon and Chromium, Tungsten, Molybdenum, Vanadium and Manganese. Hardness values of 50 to >64 HRC are achieved by hardening and tempering the tool steel using the recommended heat treatment process.

voestalpine High Performance Metals offer a extensive selection of tools steels from our BÖHLER and UDDEHOLM brands. With over 250 different grades available to choose from – each offering unique chemical compositions and material properties – we have material grades designed to perform in the most demanding environments.

Wear Resistant Grades

The excellent combination of toughness and wear resistance offered by tool steels makes them an ideal replacement for traditional quench and tempered materials in a range of applications where abrasion is a major issue. The table below shows a selection of the wear resistant grades available.

| Product | Specification |

|---|---|

BÖHLER K110 | 1.2379, AISI D2 |

BÖHLER K340 | Patent |

BÖHLER K700 | 1.3401 |

Uddeholm Calmax | 1.2358 |

Uddeholm Sleipner | Patent |

Uddeholm Vanadis 8 SuperClean | Patent |

Example applications:

- Drill clamps

- Spreaders

- Slurry pump valves

- Wear plates

- Gears & Shafts

High Toughness Grades

The excellent combination of high hardness and toughness offered by tool steels makes them an ideal replacement for the traditional high tensile steel grades commonly used in the mining industry. The table below shows a selection of the high toughness grades available.

| Product | Specification |

|---|---|

BÖHLER K245 | 1.2101 |

BÖHLER K600 | 1.2767 |

BÖHLER M238 | 1.2738 |

BÖHLER W302 | 1.2344, AISI H13 |

BÖHLER W360 | Patent |

BÖHLER W403 | 1.2367 |

Uddeholm Orvar Supreme | 1.2344, AISI H13 |

Example applications:

- Breakout clamps

- Retaining bolts

- Drifter pistons

- Winch jaws

- Hydraulic torque & impact tooling

Product Portfolio

The tool steel grades highlighted here are only a small selection of the high performance grades offered by BÖHLER and UDDEHOLM. If you have a specific component or application where you feel a tool steel grade could improve performance, and need advice on material selection, please feel free contact our Mining experts in Australia for a discussion:

Or contact us for a general inquiry on Mining:

Please fill out this contact form for further information:

Fields marked with * are mandatory.