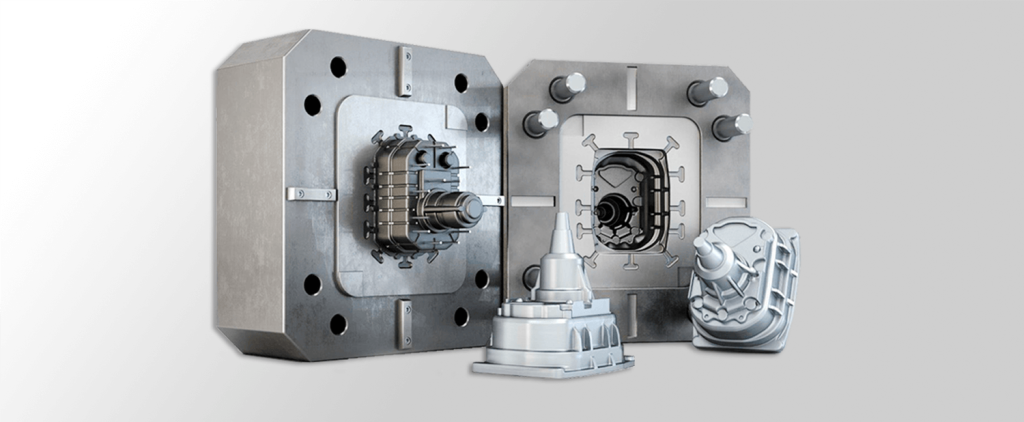

High Pressure Die Casting (HPDC)

High pressure die casting provides an economical way to manufacture large quantities of complex, highly resistant parts in aluminum, magnesium, zinc and copper alloys.

Our goal is to reduce the total cost of ownership (TCO) per produced part for our customers! This can be achieved by improving the OEE of the die casting machines or by reducing the scrap rate via innovative tooling solutions, to name some examples.

By using innovative solutions (e.g. Engineered Products with conformal cooling produced via Additive Manufacturing) our customers have reduced the cycle time by more than 30% – even for highly complex parts. Additionally, we support our customers in finding the right combination of tooling materials and required services for their specific parts, to significantly increase their production runs and produce higher quality parts.

PRODUCTS & SERVICES FOR HIGH PRESSURE DIE CASTING

Engineered Products

Materials

Services

Request more details!

Please fill out this contact form for further information:

Fields marked with * are mandatory.