End-to-End Value Chains in Plastic Mold Making

From Steel Powder to Finished Mold Insert

Leveraging our comprehensive technological expertise—from design and engineering to the selection of optimal materials and heat treatment, through to additive manufacturing and downstream processes such as texturing and coating—we have a deep understanding of the complex interactions within injection molds. Collaborating closely with our customers, we develop customized solutions that are perfectly tailored to their unique requirements.

Design and Engineering

Additive manufacturing offers maximum design freedom in conformal cooling layouts of tool inserts, sensor integration and weight reduction. With the engineering know-how of the voestalpine Additive Manufacturing Center, we can significantly shorten the innovation cycles for your applications and products.

Additive Manufacturing

Thanks to the combination of powder and processing parameters developed by us, our components achieve a density of up to 99.997%. With our corrosion- and wear-resistant premium powder materials by BÖHLER/Uddeholm, we provide the ideal solution to enhance tool life, reduce cycle times, and maximize production efficiency for your applications.

Machining and Polishing

Through optimized processing parameters and precise downstream heat treatment, our additively manufactured tool inserts deliver mechanical properties and polishability comparable to those of conventionally produced parts. The absence of pores ensures a flawless, high-gloss polish (voestalpine eifeler Coating), making these inserts suitable for all molding applications.

Laser Texturing

Eschmann Textures offers a comprehensive range of surface texturing technologies to create customized, visually and haptically appealing surfaces according to the customer’s individual requirements. The use of ultra-short pulse lasers (femto lasers) enables a perfect interplay of design and function.

Coating

The coatings from voestalpine eifeler Coating enable precise adjustment of the surface properties and thus targeted optimization of injection molding tools. The individually tailored product solution for each customer application reduces wear and thus significantly extends the tool life.

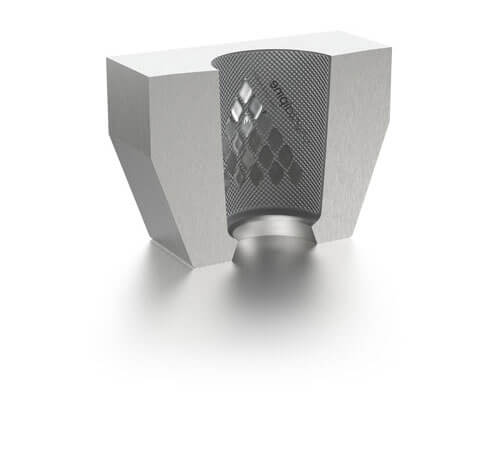

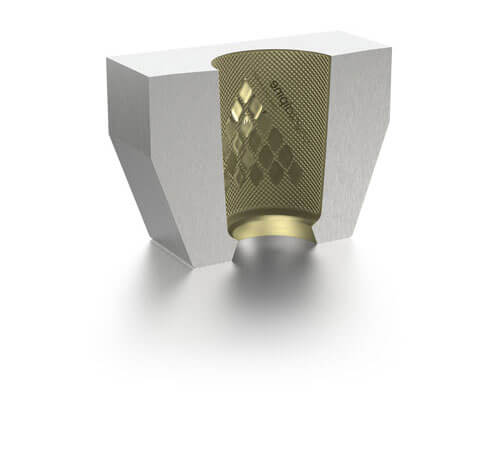

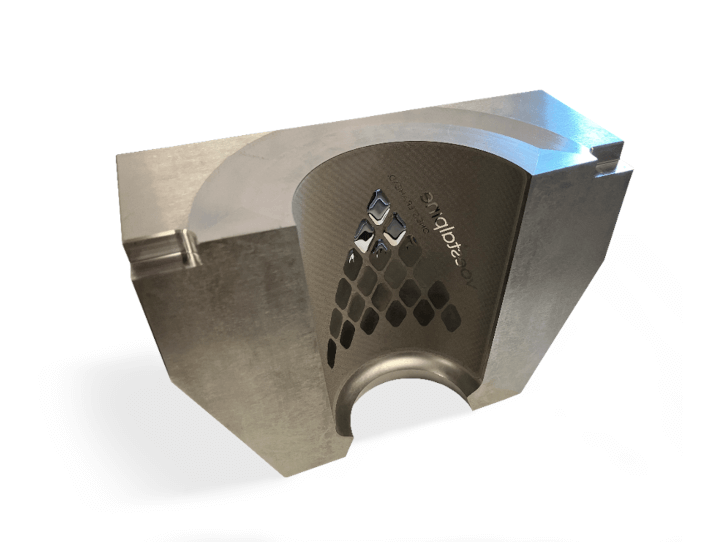

voestalpine COFFEE CUP Slider Jaws

All steps of the voestalpine end-to-end value chain can be seen in the slider jaw:

»High hardness and corrosion resistant AM powders – Additively manufactured using premium powder materials by BÖHLER/Uddeholm with hardness levels reaching up to 58 HRC.

» Enabling close tolerances in varying wall thicknesses – A design featuring parallel cooling channels ensures precise temperature control, enabling consistent part filling, even with varying wall thicknesses, during the injection molding process.

»High gloss finish on upper diamonds – Optimized additive manufacturing parameters produce pore-free tool inserts, enabling high-polish finishes that match bar material quality.

»Ultra-matt surfaces on lower diamonds – Minimizing light reflection of the plastic part with special textures.

»Soft touch feel on textured background surface – A unique texture, combined with advanced conformal cooling, delivers a soft-feel surface on rigid plastic parts.

»Wear resistance for fine textures – An enhanced coating process protects fine mold surface textures, preserving detail without compromising the microstructure.