voestalpine Solutions for Plastic Injection Molding

Technology Combinations for Innovative Product Design and Economic Production

Innovative product design and cost-efficient production demand a seamless combination of materials expertise and cutting-edge technology across the entire value chain. Achieving this requires close collaboration between all stakeholders in both the development and manufacturing stages. As a global leader in mold steel and value-added services supporting mold makers and injection molders, voestalpine High Performance Metals (HPM) division represents this collaborative approach.

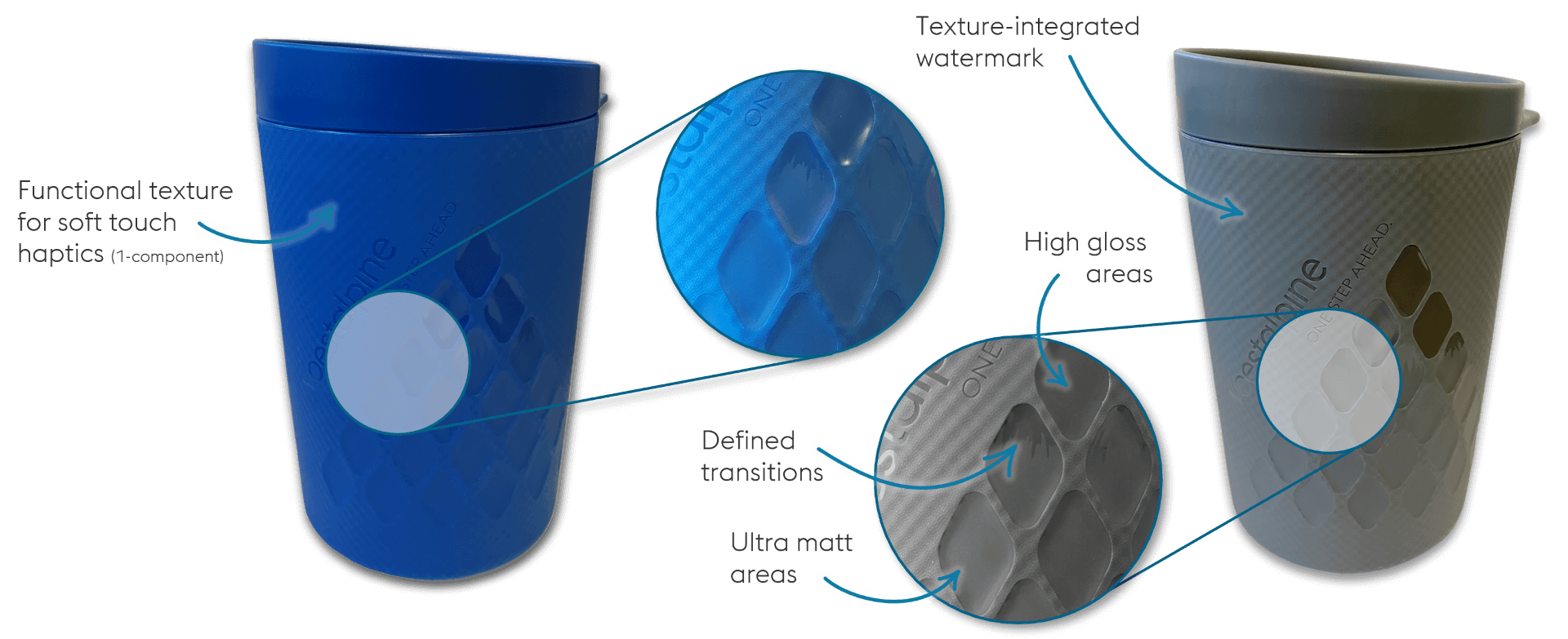

With this project, voestalpine HPM demonstrates what is possible when innovation, collaboration, and technology come together to push the boundaries of mold and part design. The presented voestalpine cup and lid, featuring integrated functional structures and textures, was created through a holistic partnership spanning product design, tool development, and the injection molding process. By incorporating conformal cooling and optimized additive manufacturing powder materials early in the mold design and optimizing cooling medium distribution and sensor integration, we were able to significantly reduce cycle times while enhancing part quality and maintaining tight tolerances.

The improved cooling performance not only allows for precise control of wall temperature in key areas but also enables superior molding of microstructures without compromising the dimensional stability of the plastic part. A tailored coating process further enhances the durability of these microstructures, providing wear resistance without diminishing their functionality.

This project is a testament to what is possible when state-of-the-art technology meets close cooperation, pushing the boundaries of mold and part design.

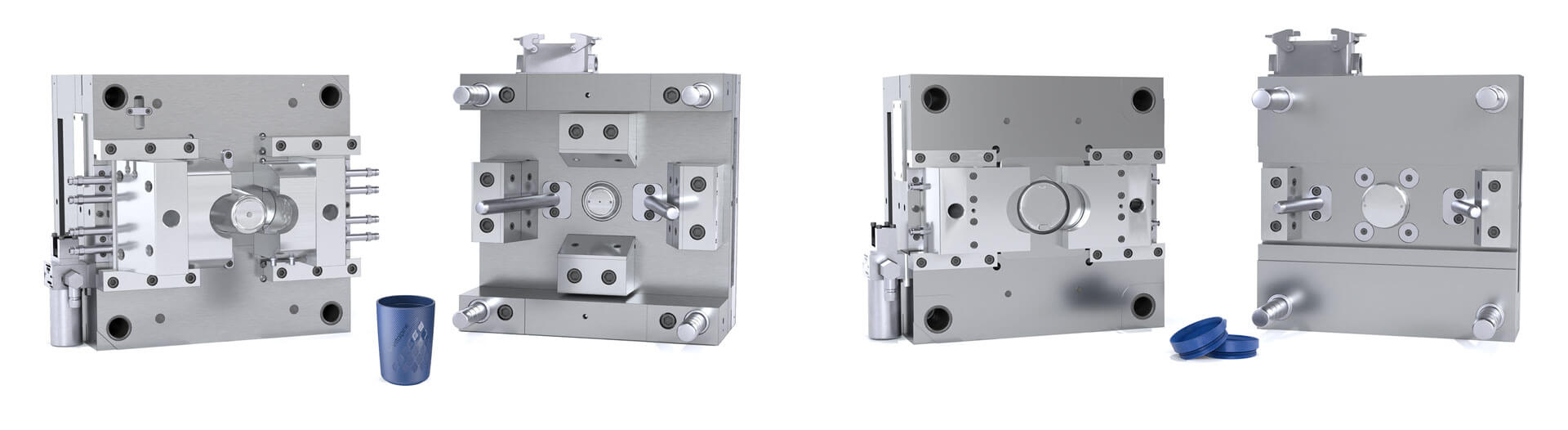

voestalpine COFFEE CUP and LID as a Technology Carrier

The coffee cup and lid molds demonstrate several advanced manufacturing technologies and their combination, thereby highlighting the integration of sustainability, efficiency, and tool-life:

»Improved Efficiency – Conformal cooling reduces cycle times and lowers the scrap rate by homogeneous temperature distribution.

»Optimized Production – Additive manufacturing reduces the mold manufacturing chain and minimizes machining volume.

»Extended Tool Life – Use of wear-resistant materials and PVD coatings to protect microstructures, leading to longer-lasting tools.

»Unrestricted Recyclability – Achieved hard and soft surface properties in a one-component injection molded part through a functional texture.

»Invisible Watermarks – Integrated into the surface for easy and clean separation during recycling processes.

Above: The voestalpine Coffee Cup with its various features enabled by the unique technology combination of voestalpine HPM