What’s all the buzz about voestalpine Engineered Products for die casting?

With voestalpine Engineered Products for die casting designed to improve productivity, we thought we’d share with you how we help our customers achieve this and how your business can also benefit.

When it comes to optimizing productivity, there are no greater masters than our friends the honey bees. Here are a few incredible facts for you about these industrious insects:

- A single beehive may contain up to 60,000 honey bees and can produce up to 25kg of honey annually.

- Honey bees are crucial pollinators to support plant diversity—visiting over 2 million flowers to produce a single kilogram of honey.

- Honey lasts virtually forever. Archeologists have discovered pots of honey well over 3000 years old and still well preserved!

What can we learn from honey bees when it comes to optimizing die casting operations? We can start by considering these questions:

- Can a die casting operation be as efficient as a beehive?

- Can casting tools be as perfect and long-lasting as honey?

- Can the entire value chain be equally sustainable?

If we could ask a queen bee, she would surely tell us that these are the very questions that need to be addressed to optimize productivity. So, how can voestalpine HPM help you come closer to achieving this?

ENGINEERED PRODUCTS FOR DIE CASTING

As a global market leader in the production and distribution of tool steel and other special steels, we use our deep understanding of materials and processing technology to produce technologically advanced Engineered Products to meet industry demands. We understand the challenges facing foundries and the importance of increasing productivity. That is why our Engineered Products are designed to enable

- Reduced scrap rate

- Improved OEE

- Optimized cycle times

- Reduced maintenance effort

- Reduced downtime

- Extended die lifetime

- Increased energy efficiency (and reduced CO2 footprint)

With our range of Engineered Products continually growing, they address the technical demands related to optimizing die casting processes. These include

- Die temperature management

- The use of new aluminum alloys

- New design requirements of the casted parts

- Complexity and size of the parts produced (thickness, etc.)

- Larger critical mold dimension (heat treatment, etc.)

- New technologies in casting, cooling, and spraying

- Surface requirements of parts produced (as casted)

You can read more about this process optimization through our recent article “The three pillars of service excellence in high pressure die casting”

OUR RANGE OF ENGINEEERED PRODUCTS FOR DIE CASTING

Our Engineered Products are produced by conventional and additive manufacturing (AM) using premium hot work steel or powder from BÖHLER/Uddeholm. Working closely with our customers to address industry demand, we continue to increase our range of these ready to use products. You can find out more about our current range here:

CORE PINS

Core pins are frequently used to cast intricate designs. Due to the extremely high thermal loads in combination with extremely hot-temperature wear on these exchangeable parts, they are one of the most critical components in HPDC and LPDC tools. With constantly rising Al-part complexity, more and more core pins are required in DC molds. Our voestalpine Core Pins are the solution to these industrial challenges. Click here to find out more.

DISTRIBUTORS & DISTRIBUTOR RINGS -CONVENTIONAL

Our ready-to-use Distributors/Rings are mainly used in two-plate die casting molds. This solution offers high-temperature wear resistance, excellent ductility (cross crack resistance), and outstanding temper back resistance. Longer lifetime, reduced downtime and maintenance effort increase the OEE for our customers, which directly results in higher productivity. Click here to find out more.

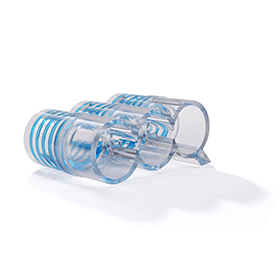

SPRUES -AM

We provide the HPDC industry with ready-to-use AM Sprues, which are mainly used in 3-plate die casting molds. Made from our premium BÖHLER/Uddeholm powders according to our customers’ needs, these AM parts contain our unique conformal-cooling design, providing significant improvement of cycle time, lifetime, and maintenance effort. Click here to find out more.

SPRUES -CONVENTIONAL

The ready-to-use sprues are used in 2 & 3-plate die casting molds. This solution offers high-temperature wear resistance, excellent ductility (cross crack resistance) and good temper back resistance. Increased and stable lifetime, reduced downtime and maintenance effort, increase the OEE for our customer, which directly results in higher productivity. Click here to find out more.

SUB INSERTS

Sub inserts are frequently used to cast intricate designs and in critical areas of wear. Due to the extremely high thermal loads in combination with extremely hot temperature wear on these exchangeable parts, they are one of the most critical components in HPDC and LPDC tools. With constantly rising Al-part complexity, more and more sub inserts are required in DC molds. Our voestalpine Sub Inserts are the solution to these industrial challenges. Click here to find out more.

WATER JACKETS -AM

Water Jackets are exchangeable tool inserts used for the casting of aluminum engine blocks. This important component is very thin and tends to have variations in thickness of its curved walls from top to bottom. Due to this design characteristic, a premium solution is required. We offer this with a combination of outstanding materials and state-of-the art processes, including heat treatment and PVD coating. Click here to find out more.

WATER JACKETS -CONVENTIONAL

Our water jackets are exchangeable tool inserts used for the casting of aluminum engine blocks. This important component, with typically very thin and variable thickness walls, must withstand extremely high thermal loads in the HPDC process. Due to this, a premium solution is required. Our ready-to-use water jackets offer high temperature wear resistance, excellent ductility, good temper back resistance and soldering reduction (PVD coating). Increased stable lifetime, less down-time and reduced maintenance efforts improve our customers’ OEE which directly results in increased productivity. Click here to find out more.

CHILL BLOCKS

voestalpine wave design allows a large gap size (up to 1.3mm), which enables a consistently high venting performance. During the opening process, the special wave geometry leads to a self-deformation in the forced venting area, thereby lowering the removal forces and providing high process reliability.

Thanks to its robust steel design, this innovative solution is ideally suited for harsh foundry condition. Furthermore, low downtimes and less maintenance effort increases the OEE for our customers, which leads directly to improved productivity. Click here to find out more.

HOW DO VOESTALPINE ENGINEERED PRODUCTS INCREASE PRODUCTIVITY IN DIE CASTING?

MATERIALS AND PROCESSING TECHNOLOGY

voestalpine Engineered Products combine materials and processing technology with a global sales and service portfolio to enable our customers to increase productivity in their die casting operations.

Along with conventional manufacturing with premium tool steels, our technologies include

• Additive Manufacturing

• Coating

• Heat Treatment

• Machining & Cutting

• ABP Surface Treatment

• Texturing

We also offer a world-class global warehousing solution, allowing our customers to benefit from the shortest possible delivery times.

By using voestalpine Engineered Products in their die casting operations, our customers can achieve a level of production efficiency that would make even honey bees buzz. And the casting tools produced may have an extended lifetime no less impressive than that of golden honey.

WE TAKE THE TIME TO UNDERSTAND YOUR PRODUCTION NEEDS

voestalpine HPM is committed to fostering long-term partnerships with our customers. We understand the importance of taking the time to step back and appreciate the full picture when it comes to our customers’ production needs. When you partner with us, our experts make it their business to understand your main production issues.

Like those industrious honey bees, we understand that good communication is essential for increasing production efficiency and reducing costs. You can read more about how we develop long-term partnerships with our customers in our recent article “How to reduce costs in high pressure die casting”

A GLOBAL NETWORK OF INDUSTRY EXPERTS READY TO HELP YOU

With a global sales and service network of 140 locations on all continents, we serve our customers wherever they are and in virtually every major industry. We also invest in our people, ensuring that their industry expertise and experience in production and value-added services can best help our customers.

When it comes to high pressure die casting, we have experts in every region ready to work with you. You can find out more about them in our recent article “Why the top foundries forge long-term partnerships to secure their success”

SUSTAINABLE PERFORMANCE

As a global company, we see it as our duty to seize opportunities to make our business and those of our customers as climate friendly as possible. Our range of Engineered Products have been designed with this in mind. Together with our customers, we aim for solutions as sustainable as those perfected by the honey bees. You can find out more about how we make performance more sustainable by reading our inSPire sustainability framework here.

READY TO MAKE YOUR DIE CASTING PRODUCTION REALLY BUZZ?

You might agree that our mutual friends the honey bees are the masters at optimizing productivity, and that it makes good sense to adapt nature’s strategies to do the same. If you’re ready to make your die casting operation really buzz, why not contact our experts today?