voestalpine HPM provides the cutting edge in food safety

In this article, we explore how voestalpine High Performance Metals (HPM) is helping food producers increase their food safety standards through the use of our Engineered Products for Food Processing. As a brief background, we discuss the growing awareness and critical concerns about harmful chemicals that can enter our food supply through food processing methods, such as meat grinding. We also show how our products address these concerns.

We begin by highlighting how leading European organizations and authorities publish papers and guidelines that address these food industry concerns:

EDQM: European Directorate for the Quality of Medicines and HealthCare

The European Directorate for the Quality of Medicines & HealthCare (EDQM) is a directorate of the Council of Europe. It protects public health by developing international quality standards for medicines and health products. They collaborate with member states, experts, and stakeholders to ensure the availability and safety of these products. Among their various products and services, they regularly publish industry papers, including

- Metals and Alloys Used in Food Contact Materials and Articles: A technical guide for manufacturers and regulators

The technical guide details the chemical elements in metallic food contact materials, including impurities, and sets specific release limits (SRLs) where needed. It also provides updated instructions for release testing, covering sampling, measuring test specimens, and calculating results. The technical guide can be found on the EDQM website here.

EHEDG: European Hygienic Engineering and Design Group

The European Hygienic Engineering and Design Group (EHEDG) is one of the leading authorities on food safety and quality, engaging with over 50 countries worldwide. Along with providing hygienic design and engineering expertise, they are a valuable resource for industry guidelines and papers, such as

- Position Paper on the Potential Ban of PFAS on Food Contact Surfaces in Food Manufacturing/Processing Equipment

The paper calls for a balanced, risk-based approach to address PFAS environmental risks, supporting restrictions on highly dangerous PFAS while differentiating between industrial applications and consumer goods. The position paper can be found on the EHEDG website here.

What are the risks associated with Per- and polyfluoroalkyl substances (PFAS) ?

Per- and polyfluoroalkyl substances (PFAS) have come under increasing scrutiny by global environmental and health organizations. Due to their resistance to heat, water, and oil, PFAS are often used in components for food and plant equipment. However, PFAS pose significant environmental threats and potential health risks due to their durable nature, leading to their accumulation in soil, water, and living organisms. The industry trend is to use suitable alternatives where available. For example, the use of non-stick coatings for applications such as cutting knives is being phased out.

Both the EDQM and EHEDG documents discussed above reflect an industry trend towards increasing food safety and quality to protect consumers from the potentially harmful effects of residual food contact materials (FCM).

What does this mean for food producers?

Increased food safety regulations directly impact food producers. Not only must they adhere to industry guidelines in compliance with regional or country-specific laws, but with growing consumer awareness about the health risks associated with food contact residues, food retailers are demanding higher food safety standards and are often prepared to pay more for the best food-hygiene results.

How can voestalpine HPM help food producers?

As the global market leader in tool steel and one of the leading suppliers of high-performance materials, voestalpine HPM produces technologically advanced products for most major industries, including the food industry.

State-of-the art food production starts with the highest quality materials

Our state-of-the-art production processes, such as protective gas electroslag remelting and powder metallurgy, enable us to meet the highest quality standards for the food industry. We test our materials specifically for the food industry, working closely with our customers to meet their demanding application needs. Our special steels for the food industry are safe for food contact materials due to their high cleanliness and corrosion resistance, ensuring they do not affect the taste of any food they come into contact with.

High demands require the highest testing standards

Industrial food processing places the highest demands on the tools and materials used. Along with high hardness and wear resistance, absolute food safety in relation to food contact materials is required. To achieve the highest standards, we use state-of-the-art laboratories at our production sites to certify our products in accordance with international standards and customer specifications. For food industry testing, we collaborate with accredited external laboratories. Guidelines such as “Metals and Alloys Used in Food Contact Materials and Articles” state the acceptable limits for metal migration and outline the testing parameters. AGES and Normpack have tested our steels and certified them in accordance with Council of Europe guidelines.

Our portfolio of high-performance materials for every food processing application

Whatever your application, we have the right material. Available in various product shapes, our portfolio includes:

- Tool Steel & High-Speed Steel: Ideal for hand knives, molds, and other tooling-type applications. We offer both corrosion-resistant and non-corrosion-resistant grades, that are certified.

- Knife Steels: Suitable for a variety of cutting and other heavy-wear engineering applications.

- Special Engineering Steels: Available in corrosion-resistant or non-corrosion-resistant grades for use where wear resistance, high hardness, and/or high-temperature performance are required.

- Powder for Additive Manufacturing: Supreme-quality powder in stainless steel and tool steel grades for use in 3D printing processes.

- Engineered Products: Tailor-made and ready-to-use parts for a range of industries, including food processing.

voestalpine Engineered Products for Food Processing are absolute game changers!

Our range of Engineered Products for Food Processing are absolute game changers. They optimize productivity, reduce total cost of ownership, enhance sustainable production processes, and elevate food safety standards, including food hygiene.

In this article we focus on voestalpine Meat Grinding Technology, but you can find out about our other Engineered Products for Food Processing on our overview page here. You can also find out more by visiting the products pages:

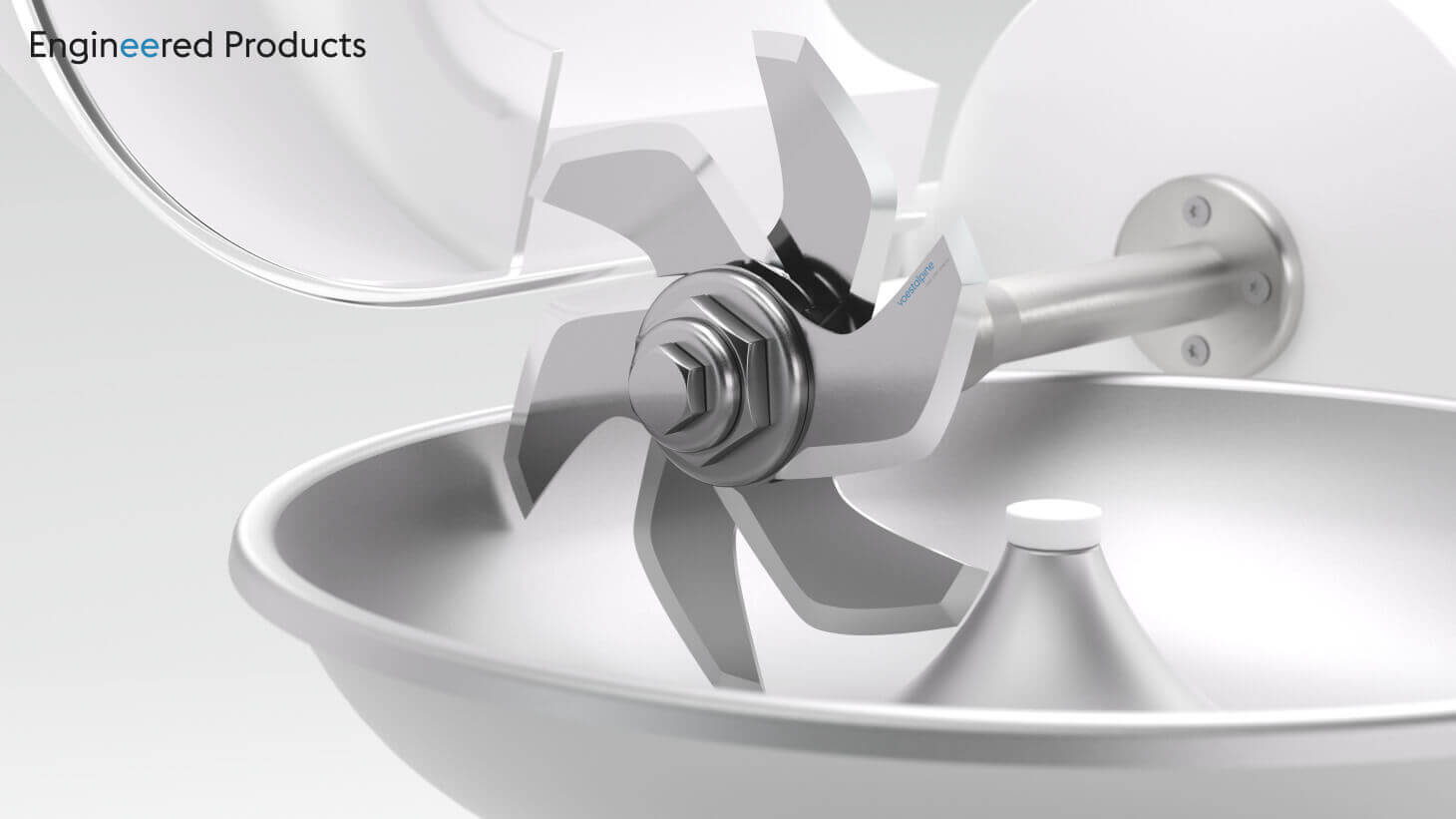

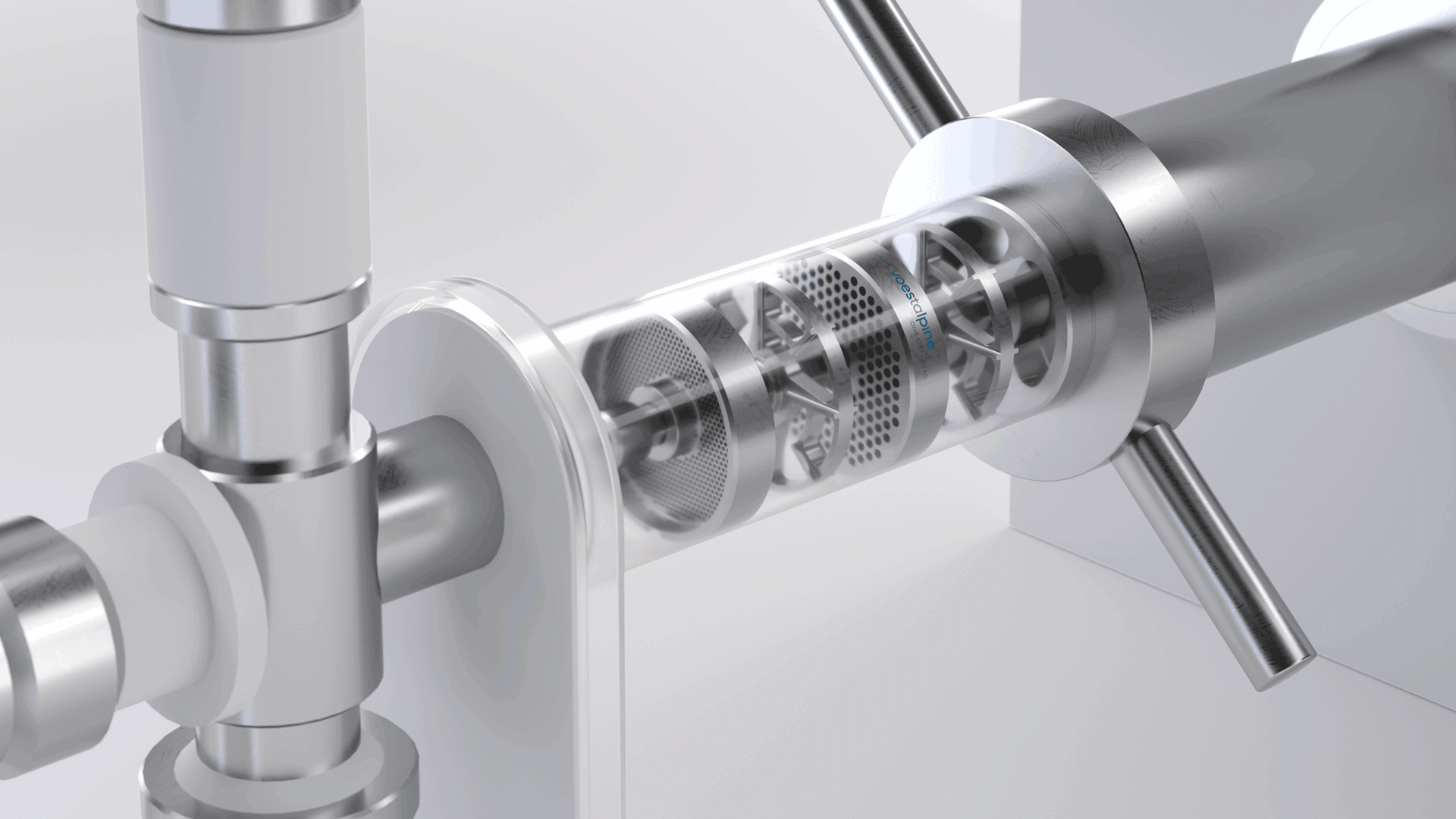

voestalpine Meat Grinding Technology

The voestalpine Meat Grinding Technology is rapidly becoming the leading choice for food producers who aim to optimize their operations and increase their food safety standards. This Engineered Product is designed for diverse applications, including ground beef, salami stuffing, and burger patty production. It is compatible with many common machine types and brands. The knives and hole plates are made from high performance materials specifically selected and heat treated to work together optimally to ensure the best cutting and grinding result. In addition, some of our parts incorporate a PVD coating which further optimizes the mechanics of the system.

Why PVD Coating is the superior solution for meat grinding

Unlike traditional coatings such as Teflon, which adds to the metal surface (and is subject to spalling or peeling—severely impacting food hygiene), PVD coating offers a far superior solution: PVD coatings are created in a high vacuum by converting metal into a vaporous state and simultaneously adding a reaction gas. They are extremely hard and very well bonded to the surface (No problems with spalling here!) There are many benefits of PVD coating, with different coatings giving e.g. advantages in wear resistance or friction reduction. You can find out more about PVD coating here.

The advantages of voestalpine Meat Grinding Technology

This ready-to-use solution enhances food hygiene by offering improved processing properties, reducing product contamination, and extending shelf life. Additionally, it significantly lowers the total cost of ownership due to much longer regrinding intervals and reduced downtime. As a customized product, it can be used in both grinding and stuffing machines.

Customer benefits

- Significantly reduced total costs of ownership

- Higher machine availability and efficiency

- Extended part life

- Prolonged regrinding cycles

- Improved cuttings results

- Less product contamination / increased food hygiene

- Reduced energy consumption

Discover how one of our award-winning customers used voestalpine Meat Grinding Technology in their burger patty production to significantly increase food safety and reduce running costs by an impressive 45%! You can read the full article here.

Ready to find out more?

As we have discussed, voestalpine HPM’s dedication to enhancing food safety through innovative materials and technologies is transforming the food processing industry. Our comprehensive range of high-performance products, including the voestalpine Meat Grinding Technology, is designed to meet the highest standards of quality and hygiene, ensuring optimal productivity and reduced operational costs for food producers worldwide.

Contact our experts to find out more about how voestalpine HPM can help you achieve the highest food safety standards in your production processes. You can contact them using the button below:

Read other articles about how voestalpine HPM is helping our customers in the food industry

Ready to learn more about how voestalpine HPM is helping our customers in the food industry? Check out our recent blog articles below.