voestalpine HPM at Fakuma 2024

One of the big highlights this year for voestalpine High Performance Metals was the enthusiastic visitor response to our exhibition stand at Fakuma 2024, the international trade fair for plastics processing. As part of the group of representatives at the stand, the team behind Engineered Products for the Processing of Plastics is pleased to share the news here.

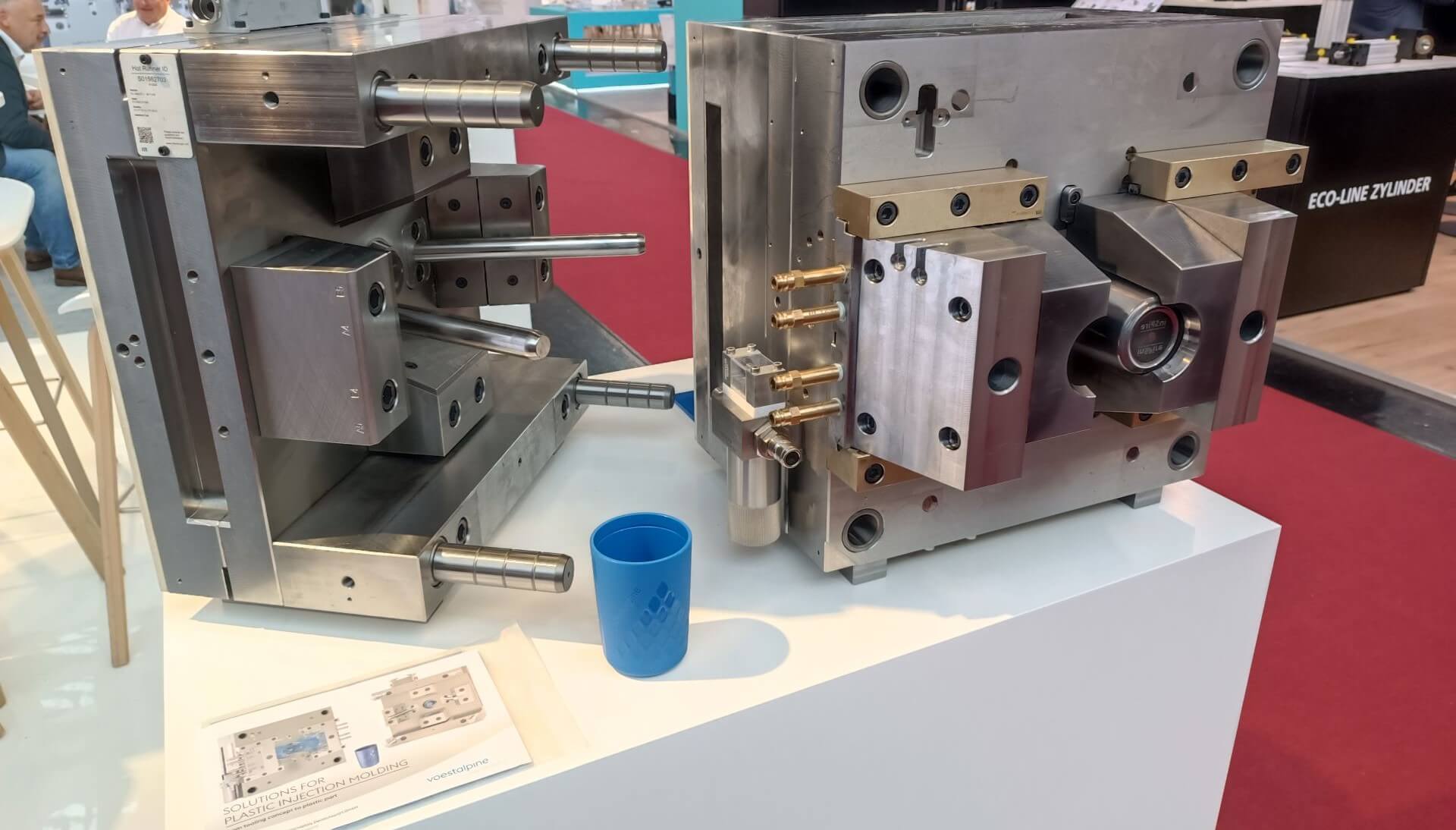

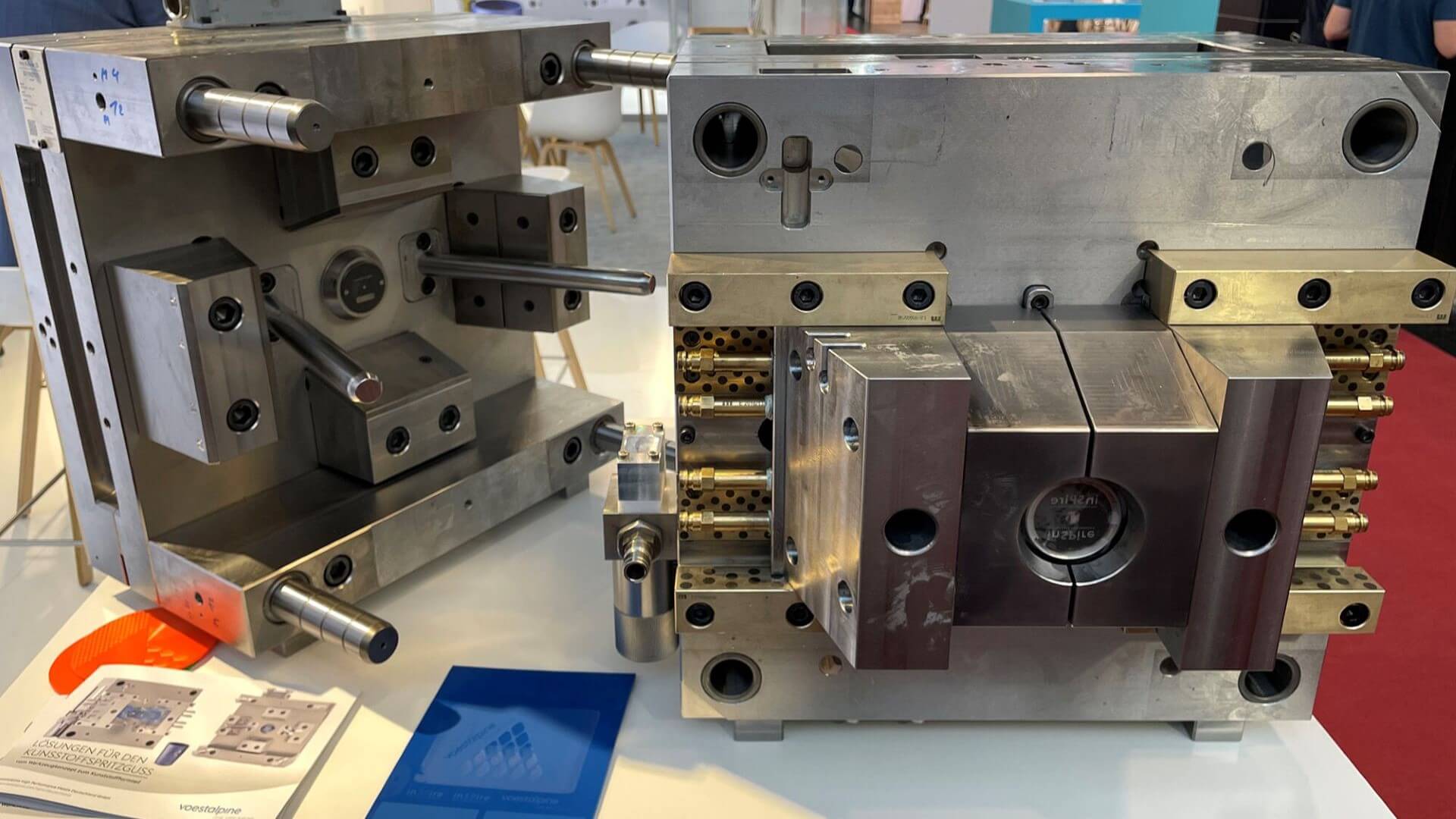

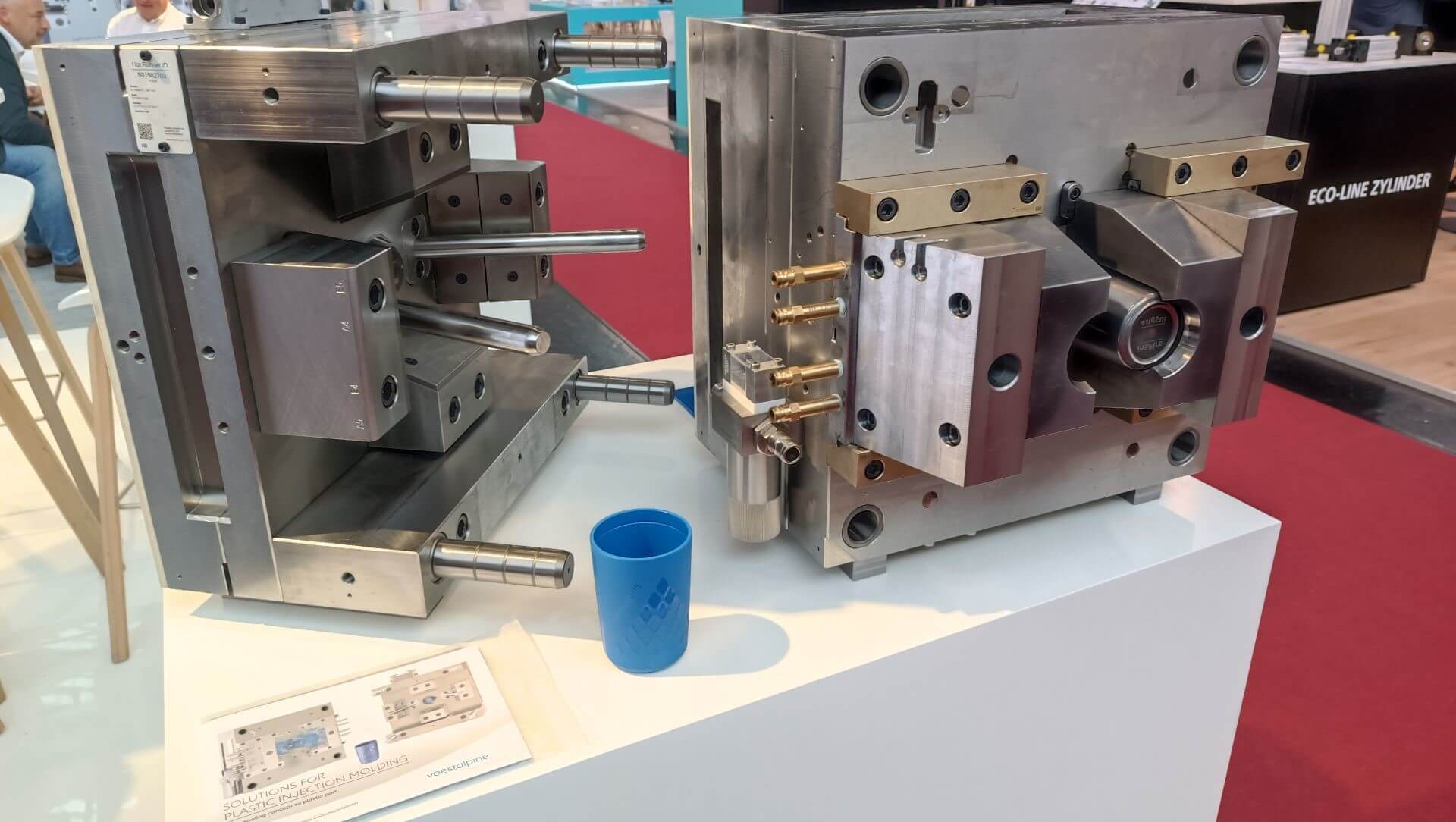

With 1,639 international exhibitors at the 29th Fakuma in Friedrichshafen in Germany, industry themes such as digitalization, optimization, sustainability, and circular economy were thoroughly explored. Exhibitors showcased their products and services aimed at increasing their customers’ competitive edge. Our experts at the voestalpine HPM stand presented our holistic approach for Injection Molds, encapsulated in the innovative technology combinations behind the voestalpine COFFEE CUP and LID Molds.

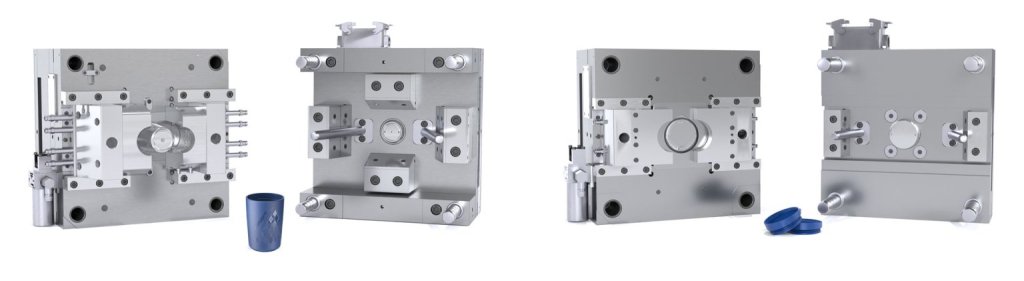

Visitors to the voestalpine HPM stand were keen to learn about the innovations in the mold design and the cost-efficient production made possible through the combination of our materials expertise and technology across the entire value chain. The voestalpine COFFEE CUP and LID (shown below) demonstrates these possibilities alongside other highlights, including sustainability and tool life improvements.

The voestalpine COFFEE CUP & LID

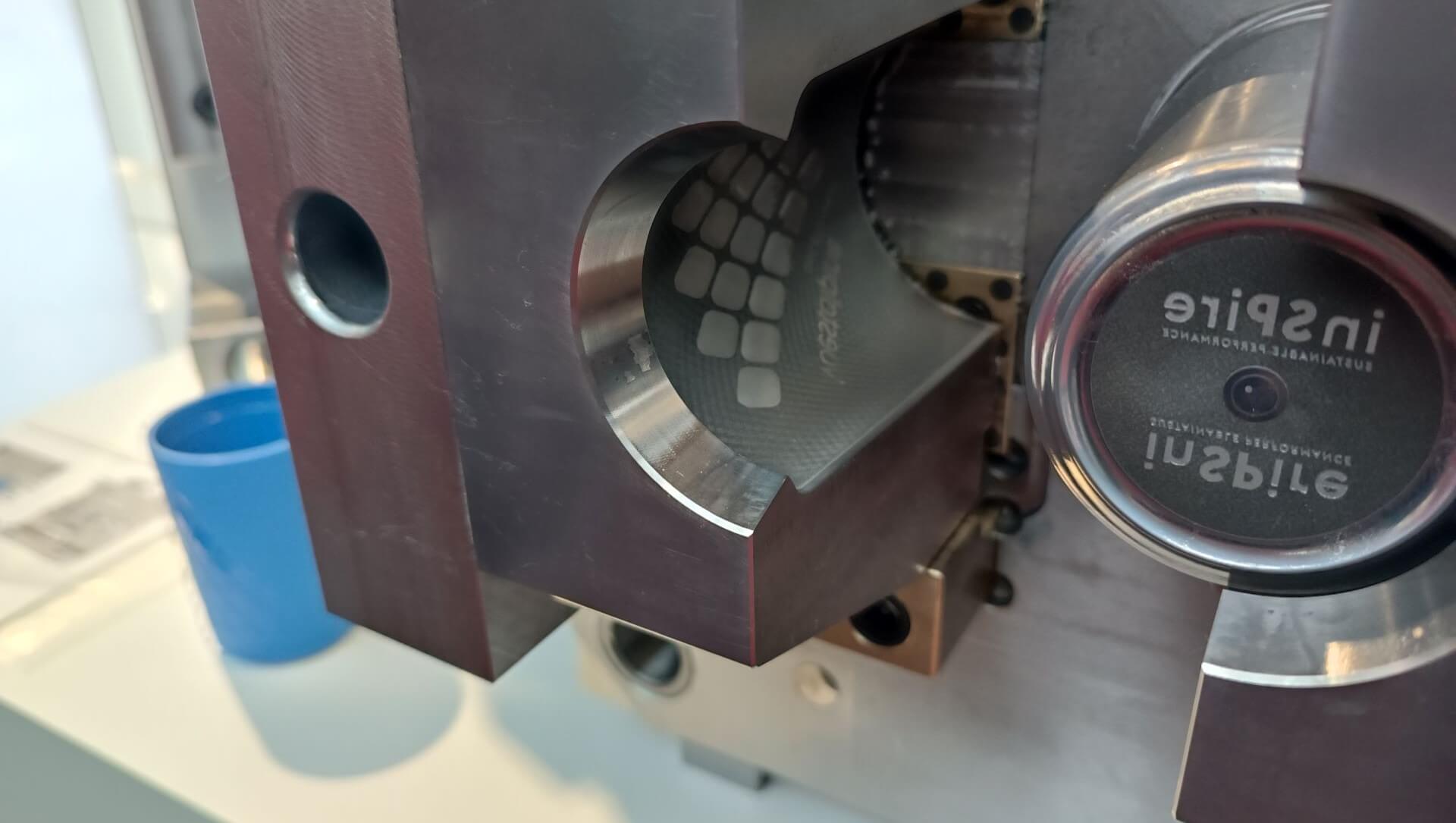

Improved Efficiency – Conformal cooling reduces cycle time and lowers the scrap rate by homogeneous temperature distribution.

- Optimized Production – Additive manufacturing reduces the mold manufacturing chain and minimizes machining volume.

- Extended Tool Life – Use of wear-resistant materials and PVD coatings to protect microstructures, leading to longer-lasting tools.

- Unrestricted Recyclability – Achieved hard and soft surface properties in a one-component injection molded part through a functional texture.

- Invisible Watermarks – Integrated into the surface for easy and clean separation during recycling processes.

Fakuma 2024 was a big team effort!

Fakuma 2024 was a big success for voestalpine HPM thanks to the outstanding team effort from both our colleagues and project partners:

Thank you to everyone involved in the Fakuma 2024 project. We look forward to reporting more news about Fakuma and the voestalpine demonstration cup and lid very soon.

Fakuma 2024 Snapshots

Find out more

Ready to find out more about HPM voestalpine solutions for plastic injection molding? You can contact our friendly experts by clicking the buttom below.