Trends in plastic injection molding: Venting structures

With most venting in plastic injection molding occurring through the parting plane, conventional venting solutions sometimes prove insufficient, leading to poor molding performance and problems with part quality. In this article we discuss the issues associated with venting (allowing air to escape during the molding process) and how Engineered Products are setting the trend with venting structures that can help you overcome these.

WHAT ARE THE MAIN VENTING PROBLEMS IN PLASTIC INJECTION MOLDING?

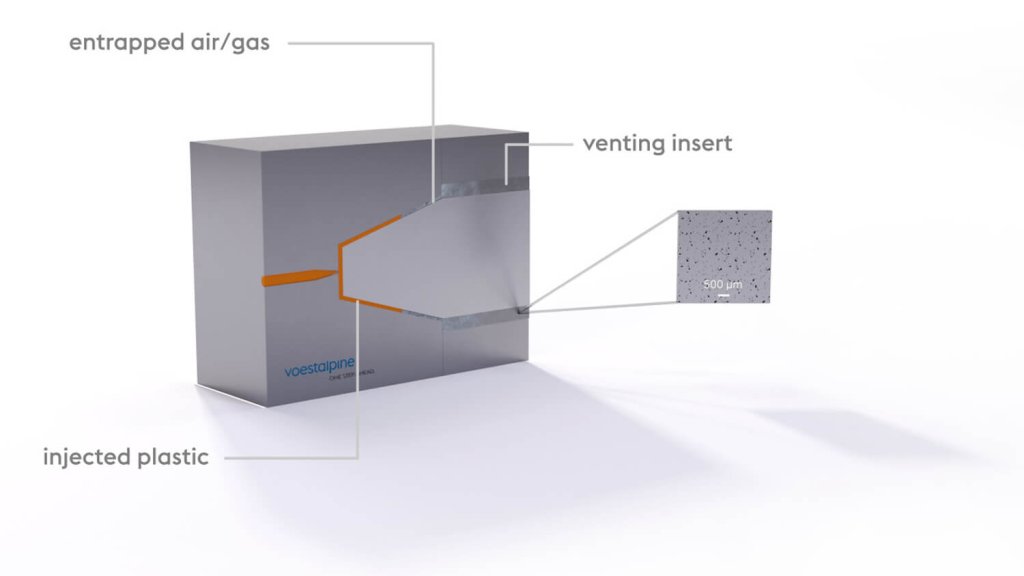

Venting is often overlooked when considering achievable part quality during the plastic injection molding process. At the start of the injection phase, the cavity is filled with air. When filling the cavity with plastic, the air is pushed out of the cavity. A pathway is required (vents) for this, otherwise the air will become trapped. If air is trapped inside the cavity, the plastic melt will push it to the end-of-fill, and the melt will compress it there. There are several defects that can arise from inadequate venting.

An air pocket at the end-of-fill can prevent the filling of the part. This can lead to an incomplete filled part, also called a “short shot.” When the air pocket is trapped between two melt fronts, the mechanical properties of the weld line can be significantly decreased.

In combination with high injection pressures and high injection speeds, the trapped air can be super-heated (>1000 °C). This may cause the plastic melt to burn, creating a black burn mark on the part. The mixture of trapped air and burned gases can also combust, leading to an effect called “dieseling.” Not only will the plastic material be damaged, but the mold steel can also be burned by the super-heated air. Depending on the molding compound, the gases created by the burning can also be aggressive and cause abrasion and corrosion of the tool steel. Wear on the mold parting lines can subsequently lead to “flash.”

Traditionally, the venting system is established through gaps between the mold components. The main vent is the parting plane of the mold, where air can escape through channels created by the mold maker. But venting is also achieved in parting lines between the mold cavity inserts and the clearance between the ejector pins and the cavity inserts.

There are also active venting standard components and passive ones, such as sintered porous plugs. The idea is to use the parting lines and the larger surface of the cavity itself. The later are limited by both their feasibility (complexity of part geometry, etc.) and the performance characteristics of the sintered porous materials. Performance problems include

- Low hardness

- Non-uniform porous morphology

- Non-stainless material (resulting in corrosion)

VOESTALPINE HPM OFFERS A BETTER SOLUTION

If you’re trying to address venting issues, voestalpine HPM offers you a better solution. As part of our Engineered Products for plastic injection molding, our additively manufactured (AM) Venting Inserts are designed to overcome venting issues inside the cavity and provide superior performance.

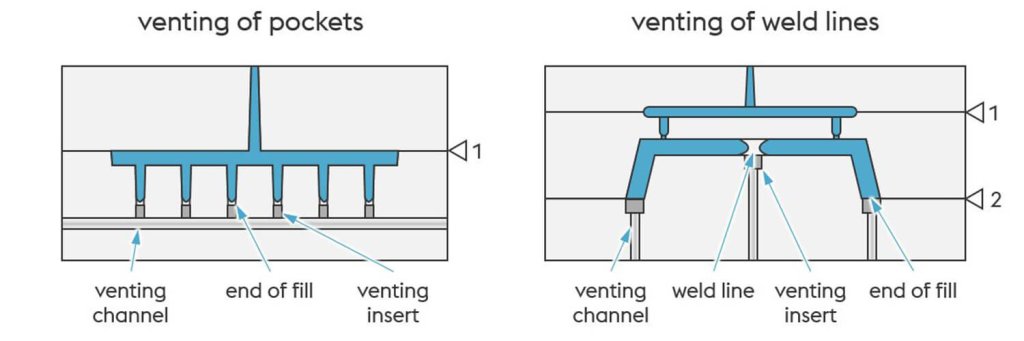

Our AM-based approach allows venting at the end of the filling path independently from the parting plane or ejector position. The venting structure can directly be integrated into the insert to allow free positioning and increase flow performance. Two examples of the application of venting inserts to overcome venting issues is shown below:

Depending on the required venting performance and molding compound characteristics, our standard-solution voestalpine Venting Structures are offered in three different densities:

- Low

- Medium

- High

They are made of our premium BÖHLER / Uddeholm materials.

voestalpine HPM also offers tailormade venting solutions for your specific plastic injection molding operation. These tailormade solutions include

- Optimized design according to your requirements

- Optimized powder for your application

- Optimized printing with the highest possible quality, reliability, and efficiency

All voestalpine HPM Venting Structures have superior surface quality, wear resistance, and corrosion resistance compared to conventionally manufactured venting solutions.

VOESTALPINE VENTING STRUCTURES ARE EASY TO CLEAN AND MAINTAIN

voestalpine Venting Structures can be backflushed to remove resin residue left on the venting surface during the molding process after demolding the part. This means that there is no impact on the cycle time, and standard maintenance intervals can be extended. During longer mold maintenance breaks, ultra-sonic cleaning of the insert can be carried out. This involves easy disassembly of the insert and ultra-sonic cleaning (with acetone or alcohol).

WHAT ARE THE VOESTALPINE VENTING STRUCTURES MAIN ADVANTAGES?

The voestalpine Venting Structures offer the following distinct advantages over conventional venting solutions:

- Increased gas flow rate

- Reduced scrap rate / Prevention of defects

- Reduced injection pressure / Energy saving

- Improved corrosion resistance

- Higher hardness leads to better wear resistance

- Longer expected lifetime

- Ease of maintenance

READY TO FIND OUT MORE?

If you would like to find out more about the trend of using venting structures in plastic injection molding, our experts are looking forward to hearing from you.

You can contact them below: