Trends in plastic injection molding: Sensorized inserts

The trend of using senorsized inserts in tools for plastic injection molding allows manufacturers to monitor their injection molding processes with the aim of increasing efficiency and part quality. In this article we discuss how the use of additive manufacturing (AM) significantly enhances this digital development and leads to improved data quality for, e.g., reducing scrap rate or increasing productivity.

HOW DO SENSORIZED INSERTS HELP THE MONITORING PROCESS?

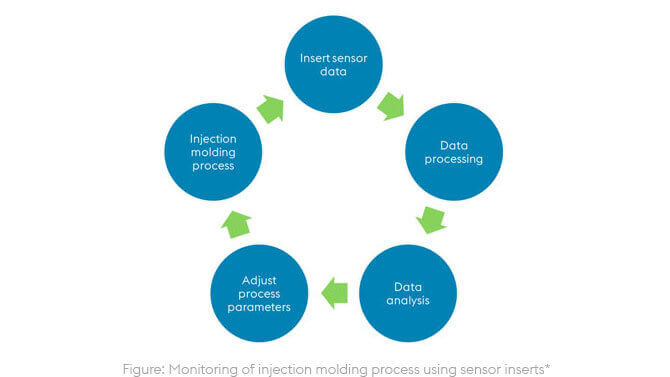

Many process parameters such as injection pressure and temperature or plastic weight can be measured by the injection molding machine. About 70% of part failures can be detected by using such machine data. However, depending on the application, additional sensors in the tool can support the measurement of quality data and thereby help to adjust the process parameters such as temperature. Refer to the figure below for a simplified representation of the process.

As illustrated in the figure to the left, with sensors integrated into the tool, real-time data can be processed, capturing potential problems and thereby adjusting process parameters accordingly. And AM provides the design freedom to enable the integration of sensors at precisely the right places without negatively impacting the insert’s cooling design.

* voestalpine provides the AM inserts and installs the sensors. Sensor manufacturing, data processing and analysis is not currently included in our scope of services.

WHAT ARE THE BENEFITS OF AM INSERTS?

In a previous article we discussed how to increase efficiency and productivity in plastic injection molding. You can read the article here. The use of AM inserts was central to this. AM overcomes many of the injection molding issues associated with conventionally manufactured tool inserts:

- Defects such as shrinkage due to inhomogeneous temperature distribution, resulting in higher scrap rates

- Longer cycle times

- High maintenance and production costs due to high scrap rate and high cycle times

- Design limitations, e.g., for conformal cooling or sensor integration

One of the many advantages of AM is the realization of conformal cooling channels in mold inserts to provide homogenous temperature distribution for reducing scrap rate and narrowing tolerances of the plastic part produced. Similar channels can be created for the integration of sensors for monitoring purposes. Certainly, sensors can be integrated into conventionally manufactured inserts. For similar design freedom in sensor placement, this usually requires a vacuum brazing process. However, the conventional process is generally more expensive than integration into AM inserts; and there are potential design issues that can negatively impact the conformal cooling performance of the insert.

Using AM inserts, designers can create channels to integrate sensors such as thermocouples or pressure sensors for monitoring. The monitoring system can thereby provide injection molders with real-time data about the mold—from temperatures, faults, to downtime and maintenance. Using thermocouples includes the following benefits:

- Time saving when setting up new molds and processes

- Sampling

- Increased process stability

- Reduce scrap rate

- Increased insert lifetime by operating under optimum conditions

- Detection of cooling blockage within a single shot

- Gather (big) data, e.g., for assisted process optimization, Industry 4.0 and quality data assignment for the OEM

And by using AM technology, designers can create the inserts with the following features:

- Sensor channels can be curved, allowing placement of sensors in crucial areas (for example, near the cavity or cooling channels). The sensors can be effectively placed wherever needed.

- Cooling channels can be adapted to integrate sensors that could not otherwise be reached without reducing cooling performance.

- Efficient heat transfer between the AM insert and sensor.

The sensorized inserts as shown in the above image were used in a joint project with SKZ – German Plastics Centre in collaboration with Cavity Eye, which provided the hardware and software for the visualization and collection of the sensor data.

HOW TO INTEGRATE SENSORS IN THE PROCESS CHAIN

If you run a plastic injection molding business, by partnering with voestalpine High Performance Metals, we help you right from the outset to integrate sensors into your production chain.

At the design stage, the sensor position and number of sensors in an AM insert is determined in direct consultation between the customer and the voestalpine Additive Manufacturing Center. Other design considerations regarding the sensor position include the minimum distance to the cavity and the minimum distance to the cooling channel.

Once the designed has been finalized, the AM insert is manufactured (including post-processing such as machining, heat treatment, and coating).

Although voestalpine does not manufacture the actual sensors or provide the cell or foundry monitoring, through customer consultation we are able to integrate the sensor/s in the AM inserts in preparation for monitoring according to the customer’s chosen monitoring system.

COULD YOUR PLASTIC INJECTION MOLDING OPERATION BENEFIT FROM SENSORIZED INSERTS?

The trend of using sensorized inserts for tools in plastic injection molding will continue to enhance manufacturing processes and digital automation. We’ll soon be publishing an exciting case study on the blog showing just this. In the meantime, our experts are looking forward to talking to you about how voestalpine HPM can help you with this. You can contact them below.