Performance Enhancing Solutions for Food Processing

HOW TO INCREASE YOUR COMPONENT LIFETIME BY UP TO 1500% ?

At our core, we are a company that believes in performance. We strive for better performance in everything we do, and this commitment to excellence extends to our work with food manufacturers. Whether you are looking for ways to improve productivity in food processing by reducing downtime or more importantly, your total cost of ownership, we have the perfect solution for you!

“Performance is in our DNA,”

DEPEND ON OUR EXPERIENCE

At voestalpine High Performance Metals GmbH, we offer exactly what you need: a dependable partner that can deliver significantly enhanced production performance by always looking for ways to improve efficiency through implementing our highclass materials and services into the process.

This commitment to excellence has led us to develop some of the most innovative solutions in the industry.

Size doesn’t always matter, but for us, it’s one of the key factors to our customers’ success. Our size and global presence has allowed us to hire world-class talent and invest in the most cutting-edge technology, which has resulted in unrivalled performance benefits for our customers. Over 50,000 people are part of the voestalpine Group and work tirelessly to develop and delight consumers every day.

In Europe, North America, and South America, we have eight production facilities. Additionally, the division has a 140-location global sales and service network that spans all continents, enabling unmatched customer reach.

THE FOOD INDUSTRY AND IT’S EVER-CHANGING LANDSCAPE

The food industry is a complex and ever-changing industry. New regulations, shifting consumer demands, and advances in technology can make it difficult to keep up.

Being responsible for the production of food, you are also under constant pressure to improve production efficiency and reduce costs. At the same time, quality standards are getting higher all the time.

It’s such an important industry, and we understand the challenges you face. That’s why we are dedicated to providing solutions that will help you not only overcome these challenges but also improve your production performance and efficiency in new ways.

We get it – we really do. And that’s why we’re here to help.

YOUR PROBLEMS ARE OUR PROBLEMS – WE’RE HERE TO SOLVE THEM

Being a food manufacturer comes with a unique set of challenges. You want to offer the best products on the market, but you also need to be efficient and cost-effective, not to mention the need to be more sustainable for the environment. The good news is that we can help you with all of that.

We know that unplanned production stops are costly. You’re running a tight schedule as it is, the last thing you need is your equipment breaking down. You’d love to be able to predict when something is going to fail so you can plan for it, better predictive maintenance, but unfortunately, equipment reliability and availability is not always very dependable.

It’s a balancing act. We understand quality products vs. lower costs, but you need to consider the total cost of ownership (TCO) when making decisions about your equipment. You might be tempted to go for the cheaper option, but in the long run, it might not be the most cost-effective.

Our experience shows us that cheap materials are not always the best option and are the cause of many issues and much unplanned downtime. So, how do you choose the right solution for your needs?

We’re here to help you make that decision.

SOLUTIONS THAT ARE PREMIUM AND RELIABLE

As mentioned above, we have invested heavily in research and development along with the latest technology to solve some of the most pressing problems facing food manufacturers. And we’re happy to say that our solutions are already benefiting customers in big ways.

We have been material experts for over 350 years, and without sounding too self-important, we know a thing or two about steel. Our materials are used in some of the most demanding applications and environments, which is a testament to the premium quality and reliability. And because we’re always looking for ways to improve, our materials just keep getting better and better.

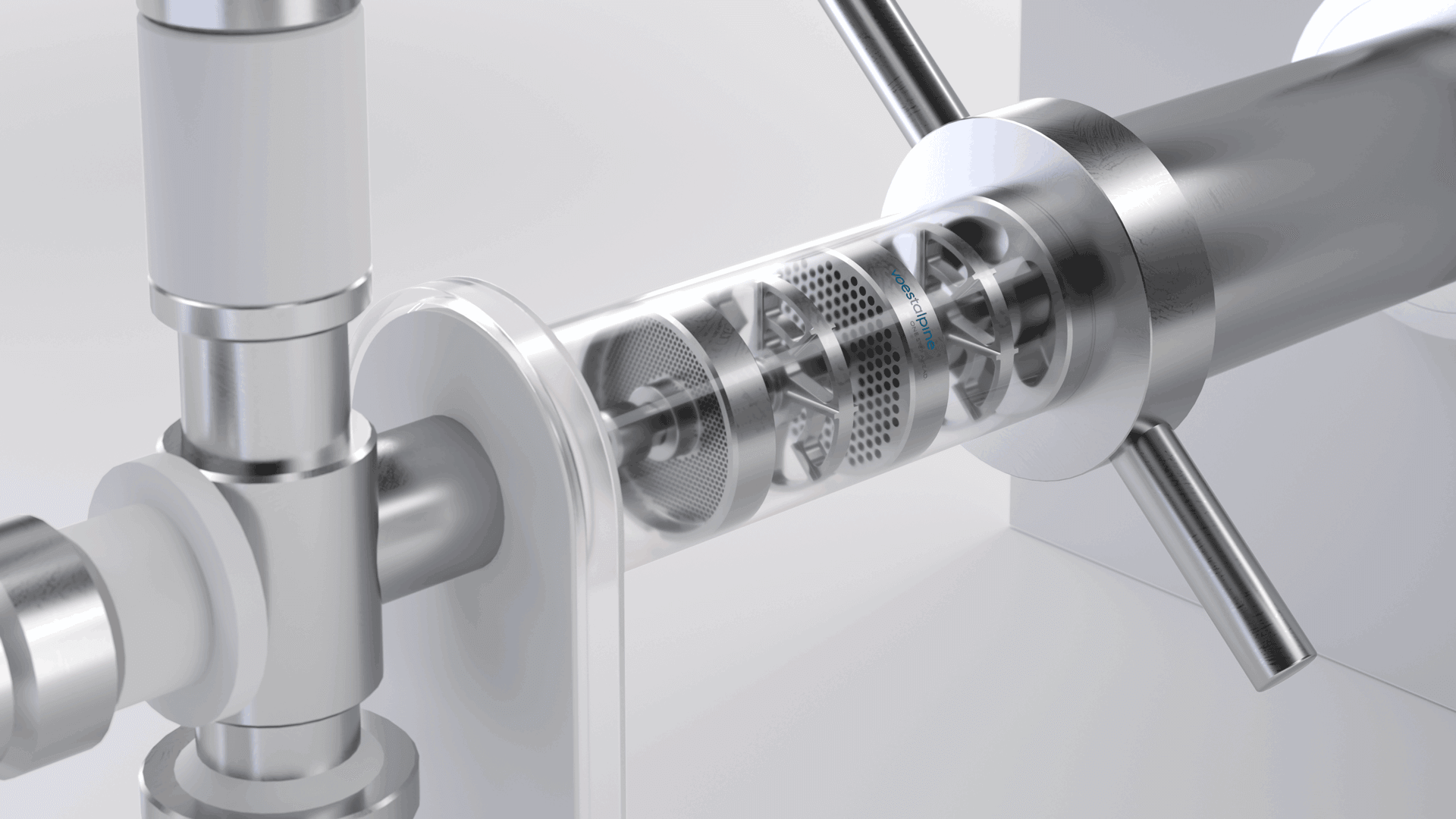

Our research has led us to identify a set of unique material grades as well as complimentary services such as heat treatment, PVD coating, and finished components that have changed the game for food manufacturers. These grades offer the properties needed to counter the challenges of the food production process while also reducing the total cost of ownership.

Some of the proven benefits for food manufacturers include:

- Enhanced Wear Resistance

- Corrosion Resistance

- Increased regrinding cycles

- Improved operating costs

- Longer tool lifetime

- Lower energy consumption

For one particular customer, we were able to improve their component lifetime by 1500%!

It sounds too good to be true, right?

We know that you’re probably sceptical, and we don’t blame you. But the fact is, our premium materials make a real difference. We’ve seen it time and time again with our customers and we’re confident that we can do the same for you.

Not only that, but we also offer a wide range of services to make sure you get the most out of your equipment. From on-site support and access to our global network of experts to training and education programs, we have you covered.

We’re here to help you solve your performance challenges so that you can produce the best products possible.