Optimize your food processing operations with voestalpine HPM Meat Grinding Technology

When it comes to optimizing food processing operations, most experts agree that a key factor is the minimization of interruptions due to maintenance breaks. All too often, operations are interrupted to replace or service worn parts. Considering the high demands on tools and material in the production process, this isn’t surprising. If you run a food processing operation, you might also agree that these breaks weigh heavily on your total cost of operation.

But why accept the ordinary performance of standard tools when there is a smarter solution—one that enables increased efficiency and higher profit? voestalpine High Performance Metals (HPM) offers a range of Engineered Products designed for pure performance, enabling you to optimize your food processing operation. You can find out about our Engineered Products for Food Processing here.

In this article, we discuss one such Engineered Product: voestalpine Meat Grinding Technology. Read on to learn more about this technology and how it can keep your food processing operation one step ahead.

MEAT GRINDING TECHNOLOGY—VERSATILE DESIGN FOR ALL MACHINE TYPES AND BRANDS

voestalpine Meat Grinding Technology is designed for diverse applications such as ground beef, salami stuffing, or burger patty production and fits all common machine types and brands. The knives and hole plates are made from voestalpine premium materials and incorporate state-of-the-art heat treatment and PVD coatings.

Regardless of the machine type in which it is used, the technology offers the following customer benefits:

- Significant reduced total costs of ownership

- Higher machine availability and efficiency

- Extended part life

- Prolonged regrinding cycles

- Improved cuttings results

- Less product contamination

- Reduced energy consumption

Depending on your operational needs, the technology can be used in both grinding machines and stuffing machines.

PERFORMANCE OVERVIEW

GRINDING MACHINES

voestalpine Meat Grinding Technology for meat grinding machines is designed for bulk production and preproduction. The technology works with most common industry machine brands, including Laska, GEA, Weiler (Provisur), Seydelmann, Kolbe, K+G Wetter, etc.

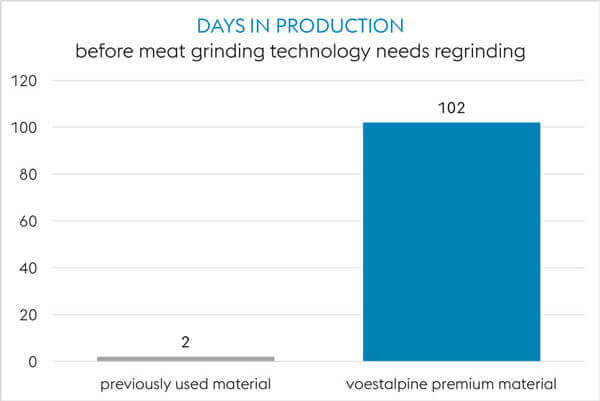

Using voestalpine Meat Grinding Technology, our customers have kept their grinding machines in operation for 102 days before regrinding of the parts was needed. This is an enormous improvement from previously having to send off the standard industry kit for regrinding every 2 days.

You can find out more about voestalpine Meat Grinding Technology and how was able to reduce their operational costs by a remarkable 45%

STUFFING MACHINES

Our Meat Grinding Technology for stuffing machines is designed to improve the production of, for example, minced meat products and sausage products. Again, it is available for all common industry machine brands include Handtmann, Vemag, Frey, Risco, etc.

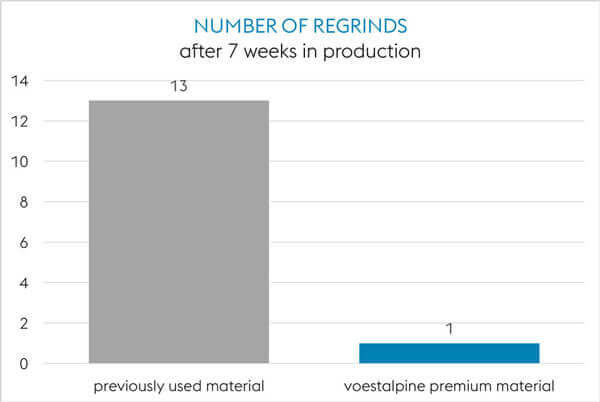

Using voestalpine Meat Grinding Technology in the production of minced meat, the parts were in operation for 7 weeks before regrinding was needed. Using standard technology, they had to stop times on average for regrinding in the same period.

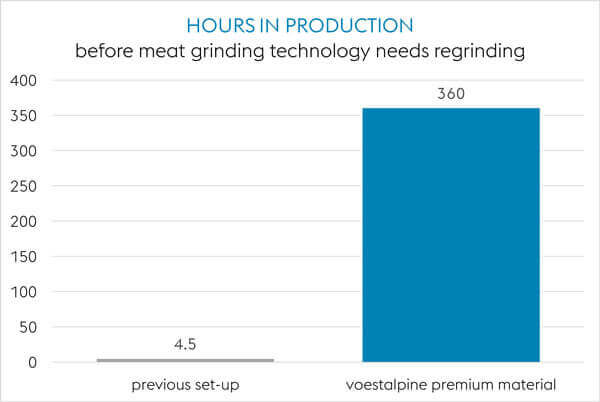

In sausage production, customers using voestalpine Meat Grinding Technology kept their stuffing machines in operation for 360 hours before regrinding was needed. Using standard technology, they had to regrind the parts after just 6.5 hours of production.

Some of the products that can be produced using voestalpine Meat Grinding Technology for stuffing machines

THE VOESTALPINE ADVANTAGE FOR YOUR FOOD PRODUCTION BUSINESS

Considering the remarkable production improvement results as shown above, you might ask yourself, “How are such great results achieved?”

This is where voestalpine’s metallurgical know-how as the global market leader in tool steel is such an advantage. Many of our customers belong to the most technologically demanding industries such as aerospace and automotive, and they are served by our premium BÖHLER / Uddeholm materials. This same state-of-the-art knowledge is applied to all our voestalpine Engineered Products, including those in Food & Beverage. And with 140 locations in 40 countries on every continent, we are there to serve our customers wherever they may be located.

WHAT ELSE MAKES VOESTAPLINE MEAT GRINDING TECHNOLOGY THE SUPERIOR SOLUTION?

voestalpine Meat Grinding Technology incorporates parts made from high performance materials specifically selected and heat treated to work together optimally to ensure the best cutting and grinding result. In addition, some of our parts incorporate a PVD coating which further optimizes the mechanics of the system.

Unlike traditional coatings such as Teflon, which adds to the metal surface (and is subject to spalling or peeling), PVD coating offers a far superior solution:

PVD coatings are created in a high vacuum by converting metal into a vaporous state and simultaneously adding a reaction gas. They are extremely hard and very well bonded to the surface – no problems with spalling here. There are many benefits of PVD coating, with different coatings giving e.g. advantages in wear resistance or friction reduction. You can find out more about PVD coating here.

Image left: Hole plates with PVD coating.

Our latest technology is also developed within the framework of our sustainability platform inSPire. It undergoes state-of-the-art laboratory testing and accreditation to the highest standards.

A GLOBAL BUSINESS WITH EXPERTS READY TO HELP YOU

Wherever your business may be located in the world, our experts are ready to listen to your unique production needs and to help you optimize your productivity.

Our Food & Beverage experts at Interpack 2023

From left to right:

Josef Michailov, Senior Business Developer

Kay Fisher, Head of F&B Platform

Valentina Greul, Junior Segment Manager

Markus Lamche, Development Engineer