How to integrate digital watermarks into your plastic injection molding process

In this article we discuss how the drive towards a circular economy for plastic packaging has led to new technologies such as digital watermarks to enable accurate sorting and high recycling rates. We also look at how digital watermarks are integrated into the plastic injection molding process and how Eschmann Textures– a part of the voestalpine High Performance Metals division–provides the expertise in laser texturing to make this possible.

ABOUT DIGITAL WATERMARKS

The drive to create a circular economy for packaging and to end plastic waste in packaging has led to new challenges and opportunities for plastic injection molders. One significant opportunity is the integration of digital watermarks in the plastic part via the injection molding process. These small and almost invisible codes that cover the plastic part can be scanned during the recycling process to enable accurate sorting and high recycling rates.

The Initiative HolyGrail 2.0 has been driving this pioneering technology to create a solution for higher recycling rates primarily for plastic packaging in the EU. With the organization headed by AIM European Brands Association and Alliance to End Plastic Waste, the impacts and benefits of this technology are aimed globally.

THE ADVANTAGES OF DIGITAL WATERMARKS

The drive towards a circular plastics economy has already yielded technologies that allow high-speed sorting rates in the recycling process. Many plastic waste properties can be identified using near-infrared spectroscopy (NIRS). This technology, however, has several limitations, including difficulty with the accurate reading of dark plastics. The use of identification stamps (ASTM International Resin Identification Coding System) placed on the product during the molding process has provided an alternate to NIRS. While both these methods have provided a significant step towards a circular plastics economy, it is the seamless technology contained within the digital watermark, which ultimately enables the evolution.

CURRENT STATUS OF HOLYGRAIL 2.0

The final research and development stage of HolyGrail 2.0 commenced in late 2023, with the aim of validating the technology and paving the way for market entry. The launch of a pilot market in France has also commenced. All this is ramping up to meet the 2030 European Commission deadline for when all plastic products must be either reusable or allow cost-efficient recycling. You can read more about the current status here.

WHAT THIS MEANS FOR PLASTIC INJECTION MOLDERS

With over 160 companies and organizations supporting HolyGrail 2.0, including most major branded goods manufactures and stakeholders in the packing value chain—from Amazon to Wrap (and with Pepsico and Procter and Gamble somewhere in between)—the market entry of digital watermarks for tracking plastics will have a relatively sudden and massive impact on plastic injection molding processes. Virtually overnight from a technical standpoint, there will be strong demand for the seamless integration of digital watermarks in the plastic injection molding process.

IS YOUR MOLDING OPERATION READY TO MEET DEMAND?

How well your molding operation can meet the steep demand arising from the market entry of digital watermarks depends on the steps you take today to adapt your production processes. The financial rewards for being a successful early adopter of this technology are considerable (many major companies will soon be demanding it) as too will be the risks of offering customers an ill-prepared value chain.

Fortunately, voestalpine HPM, has already developed the expertise for the integration of digital watermarks in plastic injection molds. Our experts are ready to help you increase the strength and quality of your value chain.

DIGITAL WATERMARKS IN PLASTIC INJECTION MOLDING

Digital watermarks are essentially a near-invisible pixelated barcode molded as a tessellation over the entire plastic product’s surface. The encoded information (plastic type, additives, application, etc.) can be accurately read from a database and sorted using camera-based detection systems.

KEY INTEGRATION FACTORS FOR PLASTIC PACKAGING

The digital watermark is created by direct-lasering or etching microscopic structures (0.5 to 500 µm) into the mold surface. The degree of accuracy of the transfer to the plastic part is influenced by various process parameters such as holding pressure, mold temperature, injection times, and melt temperatures.

The primary consideration for the integration of digital watermarks for plastic packaging is readability. The key challenge is to create microstructures large and deep enough to be molded and read reliably while minimizing their visual impact. Furthermore, there should be no resulting increase in melt temperature, mold temperature or cycle time.

VOESTALPINE HPM PROVIDES THE DIGITAL WATERMARK SOLUTION

When it comes to integrating digital watermarks into cavity inserts for high-quality plastic parts or plastic packaging, voestalpine HPM provides a seamless value chain.

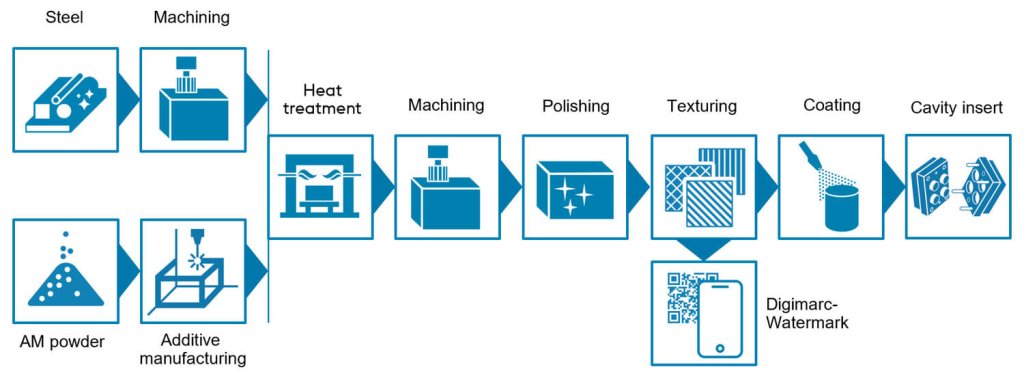

VOESTALPINE CAVITY INSERT VALUE CHAIN

Starting with the selection of the right additive manufacturing (AM) powder and ending with final PVD coating, the voestalpine cavity insert seamless value chain is shown below. The improvements in the injection molding process and in the plastic part quality are achieved through the interaction of the processes and the precise coordination of the individual steps.

Image 1: voestalpine value chain for Digimarc digital watermarks in mold inserts

You can find out more about this value chain by reading our recent blog article here: Solutions for plastic injection molding: voestalpine cavity insert – voestalpine HPM Division

Image 2 left: voestalpine cavity insert (digital watermark top left). Image 2 right: molded plastic part (digital watermark top right)

Depending on design requirement, all the individual process steps shown above in the value chain are available for the creation of a cavity insert with integrated digital watermark.

INTEGRATING THE DIGITAL WATERMARK INTO THE VOESTALPINE CAVITY INSERT

In the voestalpine cavity insert value chain, starting with the selection of the right AM powder and moving on to additive manufacturing, heat treatment, machining and polishing, the process of texturing an integrated digital watermark is one step in the manufacturing process. Through the expertise of Eschmann Textures, the cavity insert is processed using femto-laser technology to produce a visually appealing surface background texture into which a digital watermark is integrated.

Readability of the digital watermark depends not only on the polymer and the injection molding process parameters, but also on the interaction of the applied micro-structure and the PVD coating. The coating can affect the readability of the digital watermark, therefore both the laser texturing via femto-laser and the PVD coating process must be aligned.

In order to incorporate the Digimarc into the background texture, its appearance—such as gloss level and depth—must be harmonized with the design texture.

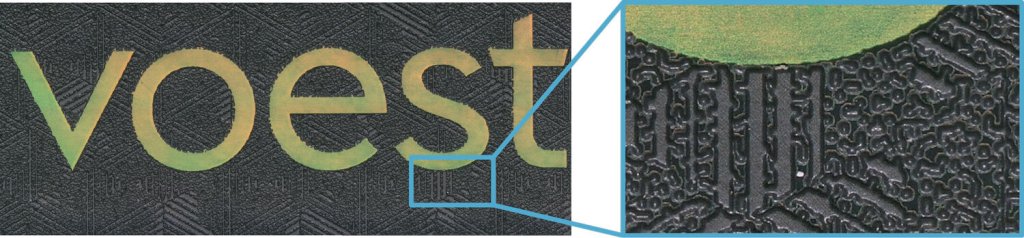

Image 3: Design integration of the digital watermark into the background texture – microscope image of the plastic part

The design integration is shown in the microscope image above, whereby the difference between the background texture, the digital watermark and the hologram (an optional design feature) is easily recognizable. The diameter of the dots varies between 20 and 100 µm and the depth between 45 and 55 µm. Both the dot diameter and depths are adjusted to the background texture to ensure a specific optical representation of the plastic part. For both, the design of aesthetic or technical textures and the “nearly invisible“ integration of the digital watermark into the texturing of the plastic part Eschmann Textures are the experts .

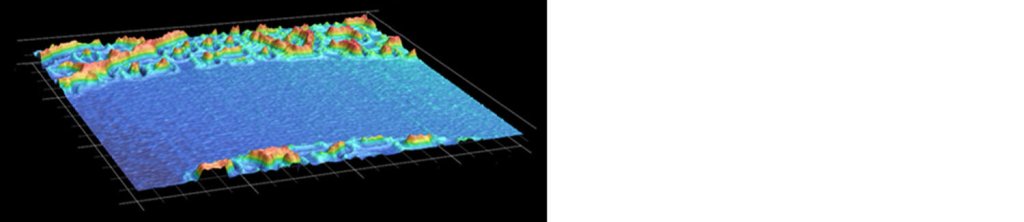

Image 3 above and image 4 below show two different sections of the plastic part. They both show the differences of the individual texture types that are integrated into the plastic part (housing cover).

Image 4: Height profile of the laser texturing that shows the differences in depth between the hologram, the background texture, and the digital watermark (microscope image of the plastic part as shown in image 2 right)

CONTACT OUR EXPERTS TO GET STARTED WITH DIGITAL WATERMARKS

If you would like to find out more about integrating digital watermarks into your plastic injection molding operation, contact our experts today. They’re ready to get you started!