How to improve your food production and save money

When it comes to demand in food production, it’s supermarkets who mostly get to call the shots. If one food producer cannot meet a supermarket’s spiraling demands on price, quality, and reliability, a competitor surely can. So much for loyalty! There’s little love lost. But if you’re a food producer, what can you do about it? How can your business remain on top in such a competitive industry?

Virgil the Roman poet offers us this proverb: “Fortune favors the bold.”

Whether in battle or in business, it takes foresight and courage to turn adversity into opportunity and thereby reap the rewards. In the food production industry (like all others), boldly embracing technology is a big part of this.

In this article we’ll show you how voestalpine High Performance Metals can help you improve your food production, save money, and have those supermarkets begging for more. We’ll also share a case study with you, highlighting how one of our customers has worked with us to significantly improve their food production.

WHAT ARE SUPERMARKETS LOOKING FOR?

If you’re a food producer, you’ll know it’s hardly rocket science. Supermarkets are looking for:

- ☑ The best price

- ☑ The best quality

- ☑ The best service

Put a tick in all of these boxes all of the time and they’ll view your business in a favorable light. Fail on just one and you’re probably headed for the dark side of the supermarket moon. Your business may be struck from their supplier list. The competition is that fierce!

IS YOUR PRODUCTION OPTIMIZED TO MEET DEMAND?

As a food producer, you may well have effective operational strategies to keep up with demand. From minimizing maintenance breaks to running multiple shifts, you know what is necessary. But while these strategies are important, they don’t necessarily eliminate the risk of an interruption to production that threatens your ability to fulfill your contract.

HOW TO MINIMIZE RISK IN YOUR FOOD PRODUCTION

Clearly there are numerous risk factors that may lead to an interruption to your food production. And while many lay in plain sight and are beyond the scope of this article (an adequate supply of raw materials, for example), there is one risk that you may not even be aware of:

YOUR SUPPLIERS WANT REPEAT BUSINESS FROM YOU!

How is this a risk?

“Obsolesence”, or the strategy of ensuring a product becomes outdated or no longer serviceable is a common business practice to push for repeat sales. How often are you having to stop for maintenance breaks to service or replace equipment parts in your production line? How often do your parts break and cause an interruption? When did you last stop to review the total cost of ownership (TCO) and ask yourself if you have the best solution?

Of course, suppliers of equipment and parts won’t draw your attention to this risk. Above all, they want repeat sales.

VOESTALPINE OFFERS YOU A BETTER SOLUTION

As a global market leader in production and distribution of tool steel and other special steels, we stake our reputation on being a reliable long-term partner along the entire value chain. With our deep understanding of materials and wide range of services, we’re able to increase the performance of your food production lines, resulting in the following benefits:

- More throughput, by means of increased machine availability, extended maintenance intervals due to longer service life of wear parts

- Better processing results and reduced energy and media consumption

- Improved hygienic design and ergonomics

- Certified food contact materials and coatings

Combined, these benefits help you to optimize your TCO and reduce risk.

We recently helped one of our customers optimize their TCO. Renowned for their tasty burgers, perhaps you have already heard of them:

STIRCHLEY BURGER COMPANY KNOWS HOW TO KEEP ONE STEP AHEAD

When it comes to high-quality halal and non-halal frozen beefburgers, you can’t go past Stirchley Burger Company Ltd in the UK. Founded in 2003 by meat-industry specialists Carl Bishop and Mark Austin, Stirchley Burger Company has grown to become an award-winning manufacturer of quality burgers. These days they deliver from between 1 and 26 pallets on a single order.

One of the many highlights in the Stirchley Burger Company’s story of remarkable business growth was their decision to use voestalpine Meat Grinding Technology in their production.

STIRCHLEY BURGER COMPANY CASE STUDY

The team at Stirchley Burgers decided to upgrade their equipment to use voestalpine Meat Grinding Technology. Made from premium materials including PVD coating, this ready-to-use technology offers improved processing properties, less product contamination and improved hygiene and shelf life.

The product offered Stirchley Burger Company the following benefits:

- Higher machine availability and efficiency

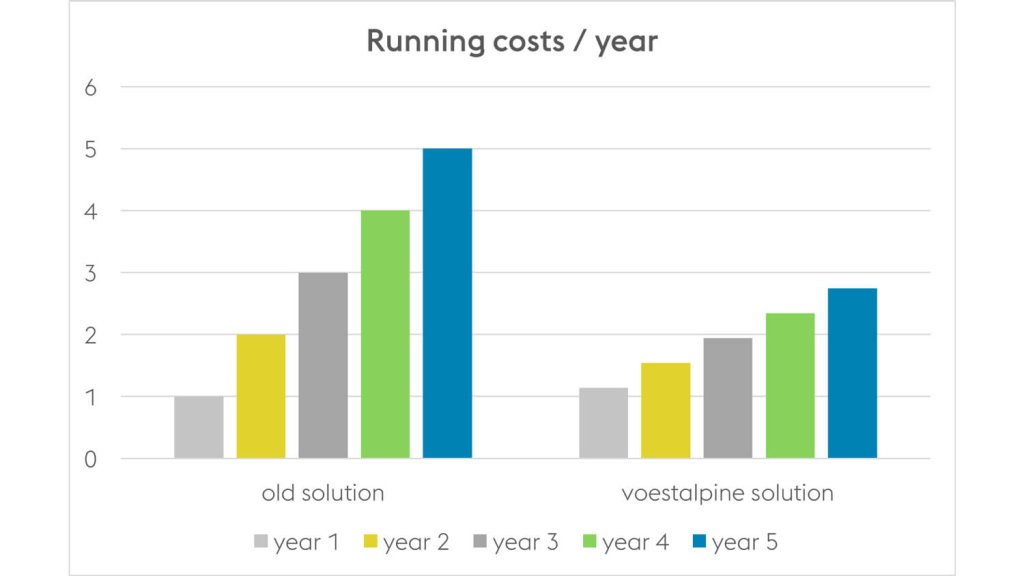

- Significantly reduced total costs of ownership

- Less maintenance (regrinding) effort

Stirchley Burgers were able to reduce their operational costs by a remarkable 45%. Furthermore, they were able to significantly reduce downtime and thereby increase equipment productivity. The voestalpine Meat Grinding Technology also gave a better cutting result (producing a better-looking burger). And the smooth PVD coating improved mince flow, leading to reduced energy consumption.

ENGINEERED PRODUCTS TO HELP YOUR FOOD PRODUCTION

Given the global reach and long history of our steel production and technology business, it may come as no surprise to you that our food industry technology used to benefit Stirchley Burger Company has been developed to increase performance in a broad range of other industries—from Aerospace to Oil & Gas and much more. We are also continuously expanding our range of Engineered Products for Food Processing. These include:

- Bowl Cutter Knives

- Chicken Processing Knives

- Film Cutter Knives

- Meat Grinding Technology

You can find out more about them here.

ARE YOU READY TO IMPROVE YOUR FOOD PRODUCTION AND SAVE MONEY?

If you’d also like to have fortune favor your food production as it has with Stirchley Burger Company, now is the perfect time to contact one of our experts. When we work with you, we’re committed to building a long-term partnership that keeps us both one step ahead. You can reach one of our experts below. They’re ready to help!

VISIT US AT INTERPACK!

You can visit us from 4 to 10 May 2023 in Düsseldorf at Interpack—the world’s largest and most important processing and packaging fair. You will find us in Booth E25/ in the components hall (Hall 18).