Higher Profits through High-Pressure Die Casting Optimization

In order to remain profitable in today’s economy, businesses must take every step possible to reduce costs and increase efficiency. One area where significant improvements can be made is through the optimization of high-pressure die casting (HPDC). In this blog post, we will discuss some of the ways that HPDC optimization can help your business reduce costs and improve profits and why a tailored approach is essential for success.

THE RIGHT SOLUTION FOR YOU

Here at voestalpine High Performance Metals we have daily interactions with the industry and extensive background knowledge in die casting. We’ve spent centuries developing the material grades to overcome the challenges facing the diecasting industry. The result is a range of high-pressure die casting materials with superior mechanical properties, like high temperature wear resistance, toughness, temper back resistance and many more.

We’re often asked what is the “best” material grade for die casting applications, but the truth is there’s not a one-size-fits-all answer. The grade of material you use will be dictated by the application, environment, and requirements. We advise on the right material grade once a full analysis has been conducted.

WHAT IS HIGH-PRESSURE DIE CASTING?

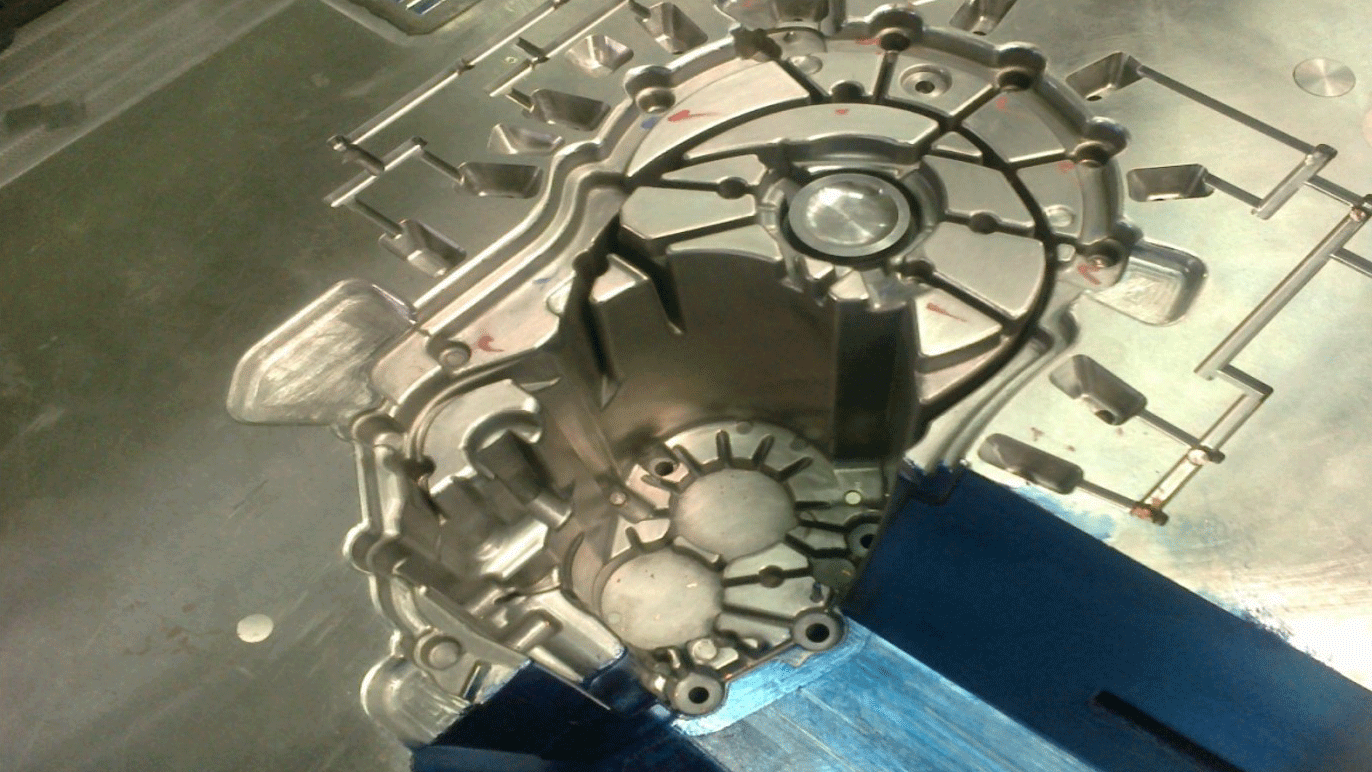

Let’s go from the start by defining high-pressure die casting. HPDC is the process of making metal parts by pouring molten metal into a mold or die. High-pressure die casting is a specialized form of die casting that uses mainly high-strength aluminium and magnesium alloys. It is used in applications where strength, durability, and precision are critical. Some examples of products that are typically made with HPDC include engine blocks, oil pans, transmission cases, and safety-relevant structural parts.

WHY CHOOSING THE WRONG MATERIAL GRADE FOR HPDC CAN BE COSTLY.

Opting for the wrong material grade will have a negative impact on the performance of your HPDC die, can increase the scrap rate, and will also negatively influence the OEE (overall equipment efficiency).

If you’re using a material with e.g. too low high temperature strength it may not be able to withstand the thermal loads created at the HPDC process. This can lead to early failures resulting in high scrap rate, high rework cost, and very high repair and maintenance efforts.

On the other hand, if you choose a material with unrequired properties for the application, you may end up paying more for the material than you need to.

Some of the key considerations you need to take into account include:

- Detailed information for the cast part

- Detailed information on the casting process

- Detailed information on the spraying technology

- Detailed information on the die temperature management (cooling technology, die temperature balance, etc.)

- Detailed information to the casting simulation, the planned casting cycles and the velocity speed.

There are many factors to be taken into consideration when deciding on the right material grade for your high-pressure die casting. Our team of experts can help you navigate this decision-making process to ensure you choose the right grade for your application.

THE BENEFITS OF HDPC OPTIMIZATION

Getting it right and taking a optimized approach to HPDC can offer a number of benefits for your business, including:

- Scrap rate reduction: by optimizing the process, it’s possible to reduce the scrap rate. This is because the process is more efficient and there are fewer opportunities for defects to occur.

- OEE (overall equipment efficiency) improvement: the optimization of HPDC can help to improve the overall equipment efficiency for die casting. This is because the process is more stable and there are fewer issues with defects.

- Lifetime improvement for the die casting die: Our HPDC optimization will help to improve the lifetime of the die.

- Maintenance reduction for foundries: Our HPDC optimization can also help reduce maintenance effort for foundries.

SEE HOW WE INCREASED TOOL LIFE BY 80%

Don’t just take our word for it! One of our customers, an automotive supplier, was struggling with increased tooling costs due to short tool lives. After a detailed exchange and discussion of their HPDC process and their technical requirements, we were able to recommend the right material with the right properties for this process so the customer could increase tool life by 80%. As a result, they experienced a significant reduction in tooling costs and made many further savings, such as scrap rate reductions and reduced maintenance effort.

The product was an oil pan for the automotive industry. Its design was challenging, with a critical shape. The delivered block weight was 1600 kg; the final part weighed just 880 kg. Significant residual stresses due to extremely high machining and significant cross section changes (from 465 mm to 70 mm thickness) brought additional big challenges for the heat treatment of this part.

The previous mold material was 1.2367 ESR mod, 45–47 HRC, with a tool life of 90.000 parts.

Our experts completed a 360-degree analysis of the environment and were able to put forward a tailored solution. We advised on the use of a specific grade from our portfolio that would improve the tooling life and cost-effectiveness with an increased hardness of 46-48 HRC, which would counter the issues that were being experienced.

The result? The tool life increased from 90.000 parts to 165.000 parts. That’s an increase of over 80%! What’s more, the customer was so impressed with the results that they have since gone on to work with us on a number of other projects.

We pride ourselves on being able to offer tailored solutions that really make a difference for our customers.

A 360-DEGREE APPROACH TO EACH CHALLENGE

As we have stated above, there are many benefits to optimizing HPDC. Scrap rate reduction, OEE improvement for die casting, and maintenance reduction for foundries are just some of the advantages that can be reached by adopting this practice. It’s not a one-size-fits-all solution, however, and the right material grade must be selected for the application. But when done correctly, the rewards can be significant.

We’re here to provide end-to-end solutions, with a big part of that being consultation. We have a deep understanding of the industry, your challenges, and how to solve them. So, if you’re struggling with tooling costs or short tool life, get in touch. We can help you find a solution that will improve your bottom line.

To learn more about how we could help you and your business, get in touch today.