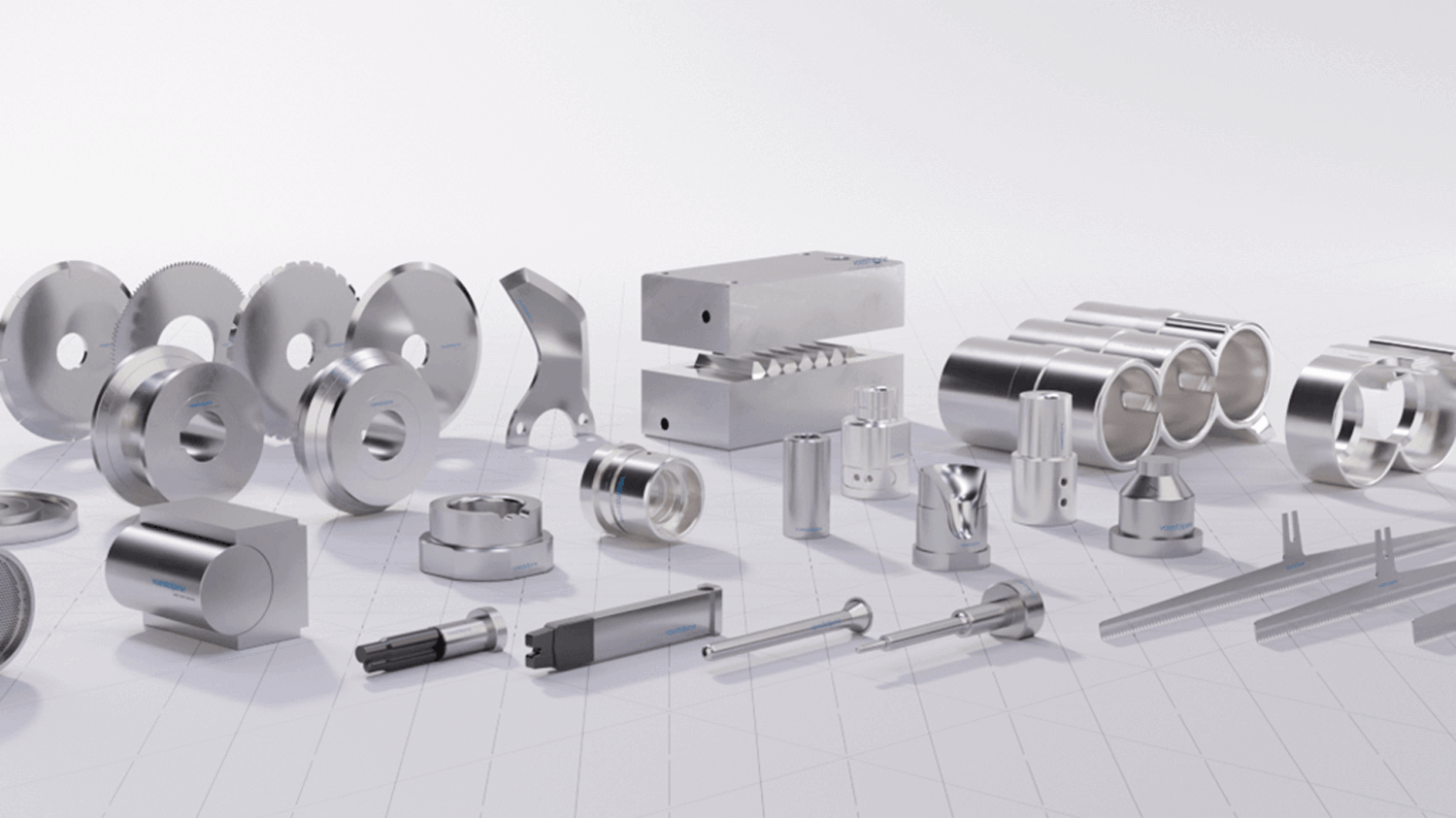

Engineered Products – designed for pure performance

Every issue has a fix, regardless of how unique. It’s true. However, many issues persist without a solution being implemented. As one of the most renowned suppliers of high performance tool steel and special materials, our experts at voestalpine High Performance Metals are well aware of the issues that plague the industry we supply. Be it in die casting, plastic injection molding, or food processing, there are certain challenges that arise over and over again. And even though these issues vary a lot depending on the application, they can almost always be solved, if addressed correctly.

A SOLUTION TO YOUR PROBLEM

Engineered Products are here to make your life easier. But how? It is, of course, easy to claim that Engineered Products are a virtually utopian fix to all your problems. So, let’s find out what it is that makes Engineered Products so special. You will soon come to find that the unique competitive advantage Engineered Products provide you with, is uniting all of voestalpine’s strengths, from consulting, production and post processing to material know how and innovative manufacturing methods, in one place.

ONE-STOP-SHOP

Engineered Products are ready to use as parts. This means they include heat treatment, coating, and final machining. Not only are these services all included in Engineered Products; they are made to perfectly synergize with one another. Our know how enables us to harmonize them in a way that would otherwise not be possible. The benefits are clear. Better performance means tools and components can be used for longer stretches of time, can increase your productivity and maintenance becomes easier and more predictable. Consequentially, this makes Engineered Products fulfil their duty – reducing the total cost of ownership. All under the roof of voestalpine High Performance Metals.

PREMIUM MATERIALS

A major asset of our Engineered Products are our high performance materials. Here, voestalpine High Performance Metals can leverage one of its core strengths. It is no secret that BÖHLER/Uddeholm materials are top notch. And since premium solutions require premium materials, it is quite clear that Engineered Products are made using BÖHLER/Uddeholms exceptional steel. This gives Engineered Products —and therefore you—an edge over the competition, and in the case of food processing knives, this can be taken quite literally.

THE NEXT GENERATION OF MANUFACTURING THROUGH ADDITIVE MANUFACTURING

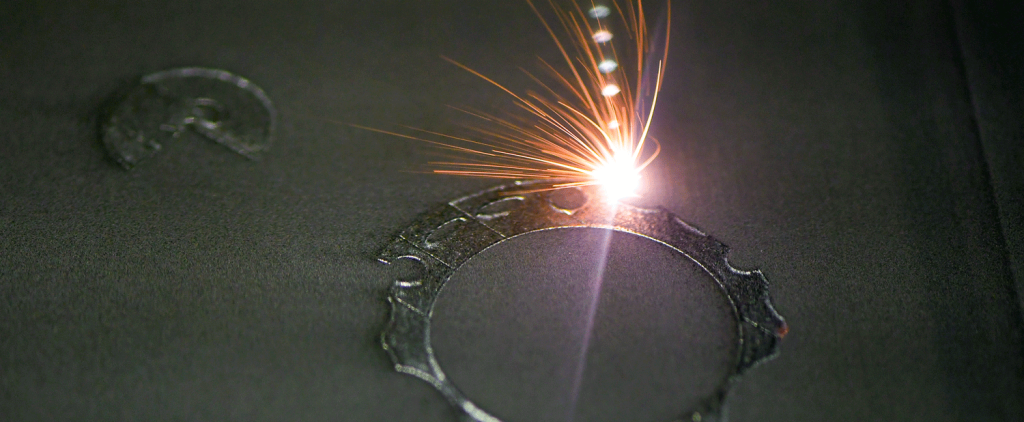

Both facts stated above are already major selling points. However, this third property is what further separates Engineered Products from the rest. Many of our Engineered Products are made using state-of-the-art metal-3D-printing, which is more commonly referred to as Additive Manufacturing. Using this method provides some key benefits. For instance, components that struggle with thermal problems like overheating can now be equipped with conformal cooling channels – and this is merely one example of how Additive Manufacturing can be beneficial. In fact, the ability to design complex shapes is one of the biggest advantages of additive manufacturing. Whereas with conventional manufacturing, highly complex shapes and forms are costly to produce, with 3D printing you can add as many edges, holes or hollow parts as you like. After all there is a reason the phrase “complexity for free” is often used regarding Additive Manufacturing.

Now let’s take a closer look at how exactly Additive Manufacturing works. In this process, layer upon layer of metal powder is fused together by precision lasers to create new shapes. What makes all of this so special is that layer-by-layer manufacturing makes it possible to create shapes and, more importantly, cavities that could not have existed in such a way before. They are designed for pure performance.

TAILOR-MADE PARTS

Finally, let’s move on to the last point—individualization. As stated in the beginning of this article, every problem, as well as every solution, is unique. A band aid might help with a scratch, but it won’t cure a cough. One can’t treat every problem the same way. They have to be looked at individually, and that’s precisely what voestalpine High Performance Metals offers—customized solutions. Every product will be made to exactly fit your requirements, to be your perfect solution.

After all, the goal is to help you maximize your production efficiency while making your life as easy as possible. Engineered Products have one job: reduce your total cost of ownership. By offering ready to use parts, voestalpine High Performance Metals can guarantee just that, in addition to the fact that you will receive the same premium quality product all over the globe.

WHAT ARE YOU WAITING FOR?

Engineered Products are high-quality, ready-to-use parts that use high performance tool steel and special materials from BÖHLER/Uddeholm, which are designed for pure performance and will be customized to solve your exact problems. They help you gain a clear competitive advantage and reduce your total cost of ownership. If you, too, want to improve your production and be one step ahead, find your local contact now.