Closing the loop with circular economy

The concept of the circular economy with a closed material and energy cycle replaces the traditional linear economy in which resources go through the process of Extraction > Production > Consumption > Disposal. At the High Performance Metals (HPM) Division, we have set ourselves the goal of consistently implementing this model under inSPire in our business processes, for example through projects to further develop material and scrap cycles and to recycle end-of-life (EOL) tools.

Metal scrap – A valuable commodity

Metal scrap is an increasingly important raw material in the steel industry. Demand for unmixed scrap in particular is always rising. This is partly due to the switch from blast furnace-based production processes to more environmentally friendly electric arc furnaces. For our melt shops, metal scrap is therefore one of the most important raw materials, which is why we are pushing for the closure of material cycles both internally and together with customers and partners. This has two main advantages. Firstly, it saves on primary raw materials, and secondly, it allows for metal scrap with a good CO2 balance. In this way, we can save valuable resources and reduce our carbon footprint.

With the help of our projects and process changes, we aim to achieve a recycling rate of secondary materials of over 90% in production by 2030, compared to 81% in 2019. We have reported more on our goals in a previous blog article.

Closing material and scrap cycles

To achieve this goal, we are increasingly focusing on projects and developments to close scrap cycles. This is done within the HPM Division not only at the production sites, but also in cooperation with the Value Added Services (VAS) companies. Processing generates scrap, which is collected by grade and returned to the production cycle. By cooperating with many of the VAS companies in Europe, we help ensure the sustainable security of supply of scrap and other critical materials.

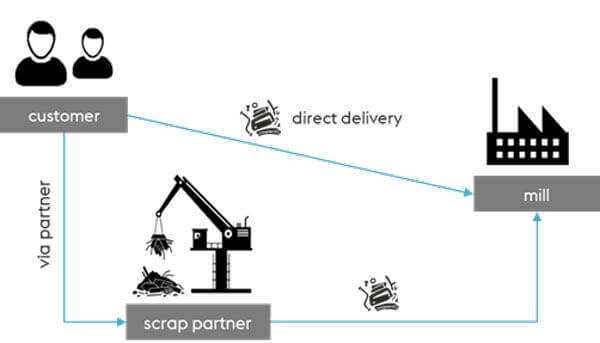

Depending on the location, the materials are recycled either via our sales companies and/or via scrap partners or—in special cases—in the form of direct deliveries to the plant.

Interest in recycled steel comes from a wide variety of industries: From aviation to the Swiss watch industry, many companies appreciate the good recycling properties of steel and the associated sustainable benefits.

“In the Swiss luxury watch industry, circular economy, reduction of the CO2 footprint and a transparent supply chain are important topics. Our customers already demand recycling rates of over 85%—and this is a growing trend,” says Carsten Harms, Managing Director at voestalpine High Performance Metals Switzerland. A successful closed-loop concept has already been established there. Customers are supplied with specially made boxes in which they collect the scrap that accumulates from our input material during production. The filled boxes are collected, exchanged for empty ones, and finally transported in bulk to our plant in Kapfenberg, where we reintegrate the scrap into our production.

Overcoming challenges with partnerships

What sounds like a simple concept brings many challenges that need to be met with innovative approaches. The international nature of the division poses particular challenges for logistics in connection with circular processes. Additionally, we are subject to country-specific regulatory requirements for the transport of goods and scrap.

With cooperations and partnerships, we build a good basis for continuously developing our logistics processes. Our strategic partners, the scrap processors, play a particularly important role with their Europe-wide network. They ensure the proper handling as well as sorting, processing, and storage of metal scrap and enable us to reuse the materials properly.

“Collaboration with our scrap partner is important so that we can effectively reuse the material at the plant. One particularly important task is the separation by grade of the alloyed scrap needed for our high-quality stainless and special steels. The fact that this is done by a reliable and qualified partner saves us from having to build up these resources ourselves,” emphasizes Heike Jauck, responsible for raw material purchasing at voestalpine BÖHLER Edelstahl in Kapfenberg.

Post-consumer waste as a source of raw materials

Post-consumer waste has particularly high recycling potential. This is waste generated by end consumers after they have purchased and used a product. For the metal industry, it represents an important source of raw materials. Many metals contained in post-consumer waste can be recycled and reused to make new products. The waste typically consists of household scrap from bulk waste collection, scrap from waste electrical equipment (WEEE scrap), and end-of-life vehicles where valuable metals, such as molybdenum or tungsten, are usually composite materials. For further processing, however, they need to be sorted by type. Separation and sorting are very time-consuming, which is why we are researching better sorting technologies to improve the quality of the scrap—for example, by using artificial intelligence (AI).

Artificial intelligence for more efficiency

AI is becoming increasingly important in many business sectors and also for us. For example, the funded “KIRAMET” project starts in 2023. It pursues the overarching goal of using AI to improve existing recycling processes and thereby making old scrap available in a recyclable way, enabling us to make our processes more climate-friendly. This is achieved by reducing the use of raw materials in production and increasing resource efficiency, allowing us to reduce our environmental footprint. By reusing and recycling materials that are already in circulation, we play an essential role in securing the supply of raw materials.

And this is where AI comes in: it can improve the sorting of waste, such as post-consumer waste, and increase potential input volumes while increasing quality requirements. Digital technologies and AI support the advancement of recycling by helping to analyze and use large amounts of data. Going forward, AI-enabled platforms are expected to bring together the supply and demand of secondary materials in the industry.

Recycling of EOL tools

End-of-life tools (EOL tools) also offer a lot of potential for recycling. These are small and large tools such as hob cutters made of high-speed steel or high-pressure die casting molds. They are used, for example, in aluminum casting in the automotive industry. For this purpose, hot aluminum is pressed into the die at approx. 700–750°C, where it finally solidifies into the desired shape. This process puts a heavy strain on the tool material, resulting in wear. The tool has to be renewed much sooner at the points where it comes into direct contact with the hot aluminum than at its outer parts. Our role in this process is to supply the high-performance steel to the toolmakers.

Together with our partner network, we are currently in the conceptual phase of further developing the EOL tool recycling. Our aim is to take the tools back from our customers or tool users at the end of their service life in order to put the raw materials they contain back into circulation. In doing so, we rely on close cooperation with scrap partners. They dismantle the tools and sort the materials they contain.

The advantage for us and our customers is that when we take back our own products, we know the source of the materials and thus also their quality and composition. In this way, we can ensure our high-performance materials meet stringent quality standards, while at the same time reducing the consumption of primary raw materials and increasing security of supply.

Sustainable management with closed loops

Many products contain valuable metals and therefore have the potential to serve as a source of raw materials themselves. A large proportion of the CO2 emissions generated in the production of high-performance materials come from the raw material supply chain and are produced during the mining and processing of alloy elements such as nickel and chromium. By recycling alloyed scrap, we aim to significantly reduce the use of primary alloys and thus CO2 emissions.

By integrating key materials that are already in circulation into our production processes, rather than always relying on new materials, we can reduce our primary raw material use and thus contribute to future security of supply with important materials, as well as reducing our CO2 footprint.