An impelling case – 3D printing on demand parts for oil & gas

Additive Manufacturing or metal 3D printing is one of the most exciting manufacturing technologies to emerge in recent decades. However, despite the excitement surrounding additive manufacturing, adoption in industries such as Oil & Gas has been limited.

The obvious benefits additive manufacturing can offer such as, JIT production (parts on demand), inventory reduction, streamlined supply chains, and improved sustainability (reducing energy use and carbon footprint) positions AM as a core pillar of the digitalization strategy for many forward thinking organizations.

Despite these benefits, technical challenges do exist when complex parts need to be certified for the Oil & Gas industry. These challenges can be overcome by partnering with solution providers who have a deep understanding of the industry and its requirements. This is how voestalpine keeps our partners – one step ahead.

UNLOCKING THE POTENTIAL OF 3D PRINTING

Woodside Energy – one of Australia’s largest energy companies – have been researching additive manufacturing technologies for many years and recently identified a key project that had the potential to deliver business value through the adoption of additive manufacturing.

Woodside Energy wanted to find an innovative solution for the replacement of stainless steel inducers on Woodside’s Floating Production Storage and Offloading (FPSO) facilities. When recently seeking to replace an inducer on the Okha FPSO, Woodside’s innovation team wondered if additive manufacturing – commonly known as 3D printing – could provide an effective solution.

These stainless steel inducers are used in sea water lift pumps – in a fabricated inducer, the weld line between the vanes and the central hub can become vulnerable to fatigue cracking. The alternative method of using 5-axis CNC machining to “sculpt” an inducer from a solid block of stainless steel is inefficient as it results in wasted material and energy.

CHOOSING THE RIGHT PARTNER(S)

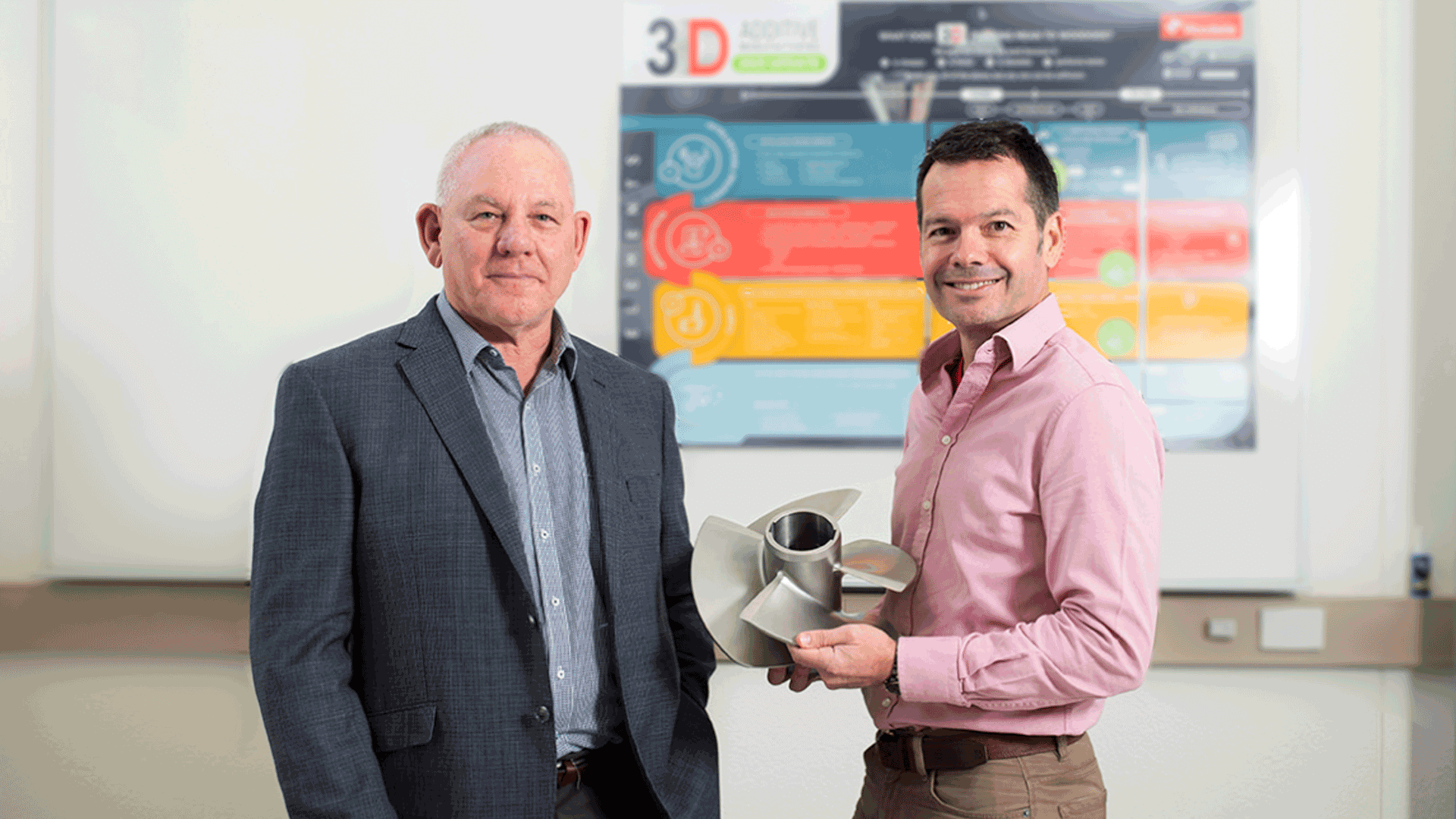

Woodside Energy engaged Geographe Australia – a Western Australian company with long experience in designing and manufacturing parts for heavy machinery and plant equipment – to reverse engineer the inducer and determine whether additive manufacturing could provide a solution.

Geographe partnered with voestalpine High Performance Metals – a global leader in the production of high-performance steels for the Oil & Gas industry and additive manufacturing solutions – to print and qualify the inducer.

“This project has been a fantastic opportunity to show the potential of additive manufacturing in oil and gas applications with our partners at Geographe.” states Lee Brindle, voestalpine’s Additive Manufacturing Business Development Manager. “The ability to print parts on demand, reducing both inventory levels and lead time, is a game changer for the industry,” Brindle says.

3D PRINTING INNOVATION – HYBRID PARTS

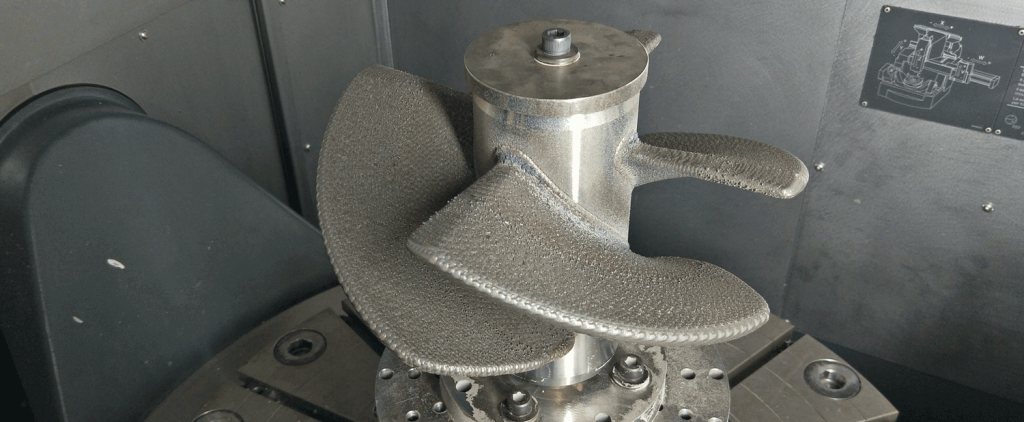

Due to the inducer size and required material Super Duplex 2507 (UNS32750), Geographe and voestalpine opted for a hybrid 3D printing solution using laser powder metal deposition (LMD / DMD). The inducer vanes are printed directly onto a central hub of the same material using the LMD / DMD system.

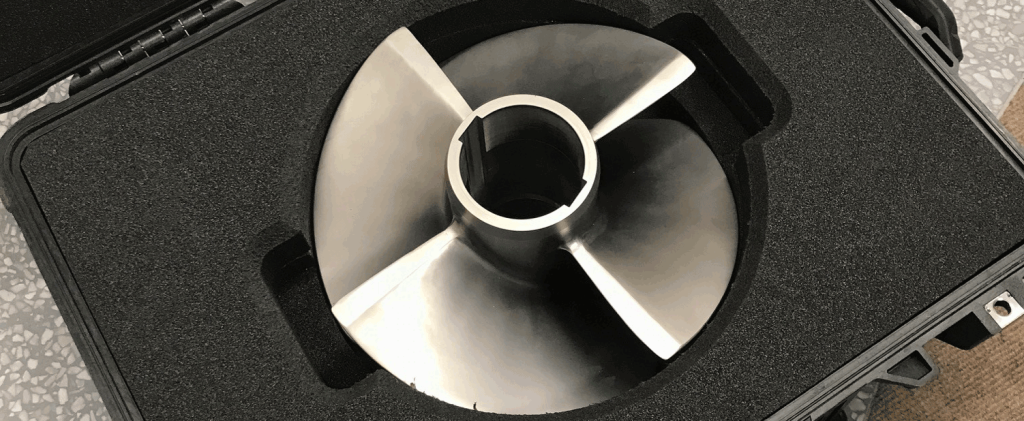

Once heat-treated, the mechanical and performance properties of the 3D printed material are identical to that of bulk Super Duplex 2507. The inducer was then machined, balanced and subjected to non-destructive testing to meet Woodside’s quality and performance requirements.

Woodside Energy Chief Technology Materials Engineer Michael Brameld said the 3D printing method offered further advantages. “Because the laser is small and concentrated, you don’t get the heat-affected issues you can have with traditional welding methods. Lower heat input results in elimination of the heat-affected zone common with traditional welding methods,” he said.

BUILDING CUSTOMER SOLUTIONS – LAYER BY LAYER

The finished inducer was delivered to Woodside after completion of a rigorous testing regime, and in a first for the company the 3D printed rotating component was installed into service on the Okha FPSO in May 2022.

“At Geographe we look to develop innovative solutions with our customers, and we are delighted to have had the chance to work with Woodside on such an important project.” says Sean Martin, Geographe’s Research, Development & Innovation Manager. “Combining Geographe’s engineering expertise with voestalpine’s additive manufacturing experience has shown additive manufacturing can be successfully deployed in the most demanding of industry applications,” Martin adds.

INNOVATING INTO THE FUTURE – ENGINEERED PRODUCTS

With our expertise in additive manufacturing, heat treatment, coating and final machining, voestalpine High Performance Metals has introduced a new product line, Engineered Products.

Engineered Products are ready-to-use parts made of exceptional steel, perfectly complemented with voestalpine’s service know-how. They cover a wide range of applications, such as die casting, food processing and plastics industry.

The addition of Super Duplex 2507 to our existing material portfolio paves the way for Engineered Products in the Oil & Gas industry. It is a segment which can make great use of the properties voestalpine can offer using its premium materials and state of the art additive manufacturing technology.

Learn more about Engineered Products and on how they are made for pure performance and take a deep dive into voestalpine’s additive manufacturing capabilities to see how your business can benefit this innovative technology or visit our dedicated Oil & Gas pages to find a solution tailored specifically to your needs.