Core Pins

Core Pins

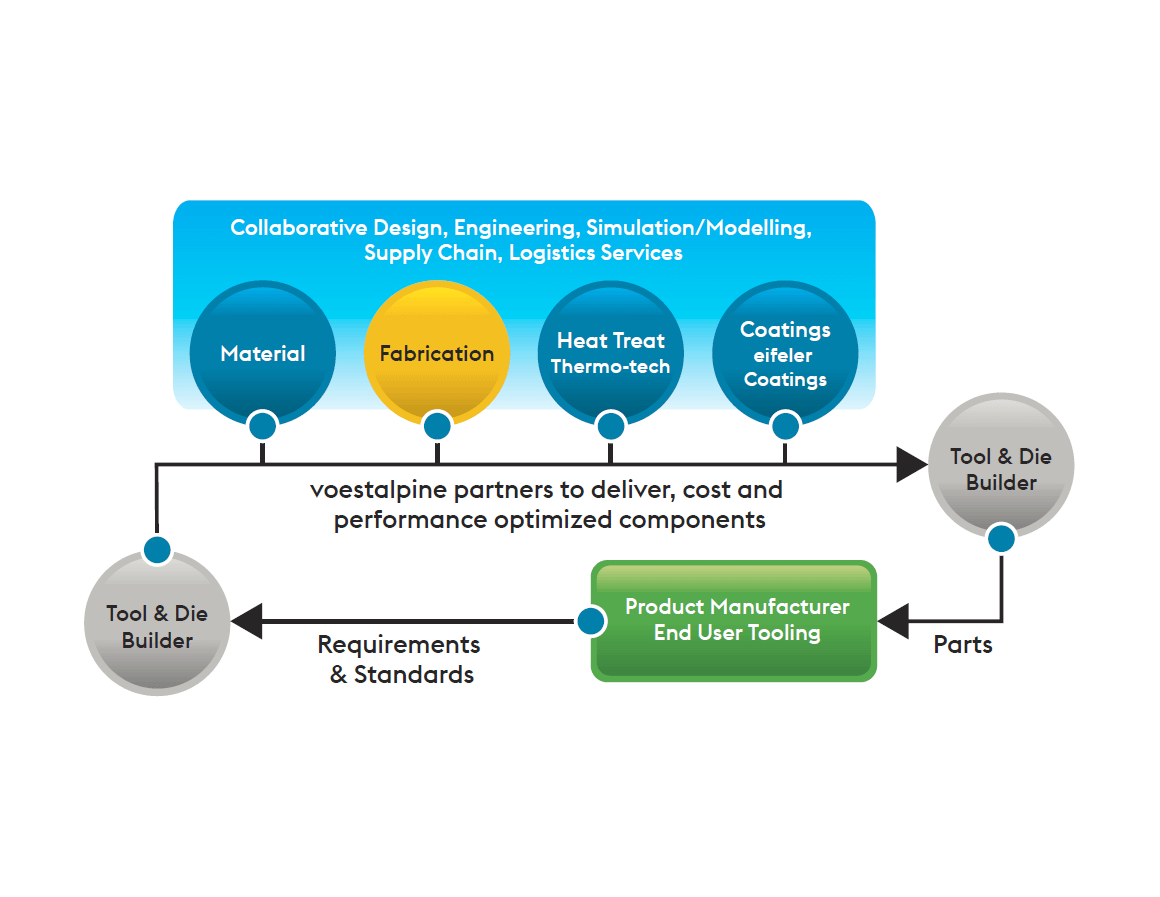

voestalpine provides tailored solutions by integrating design, material selection, thermal

processing and PVD Coatings to deliver optimized solutions.

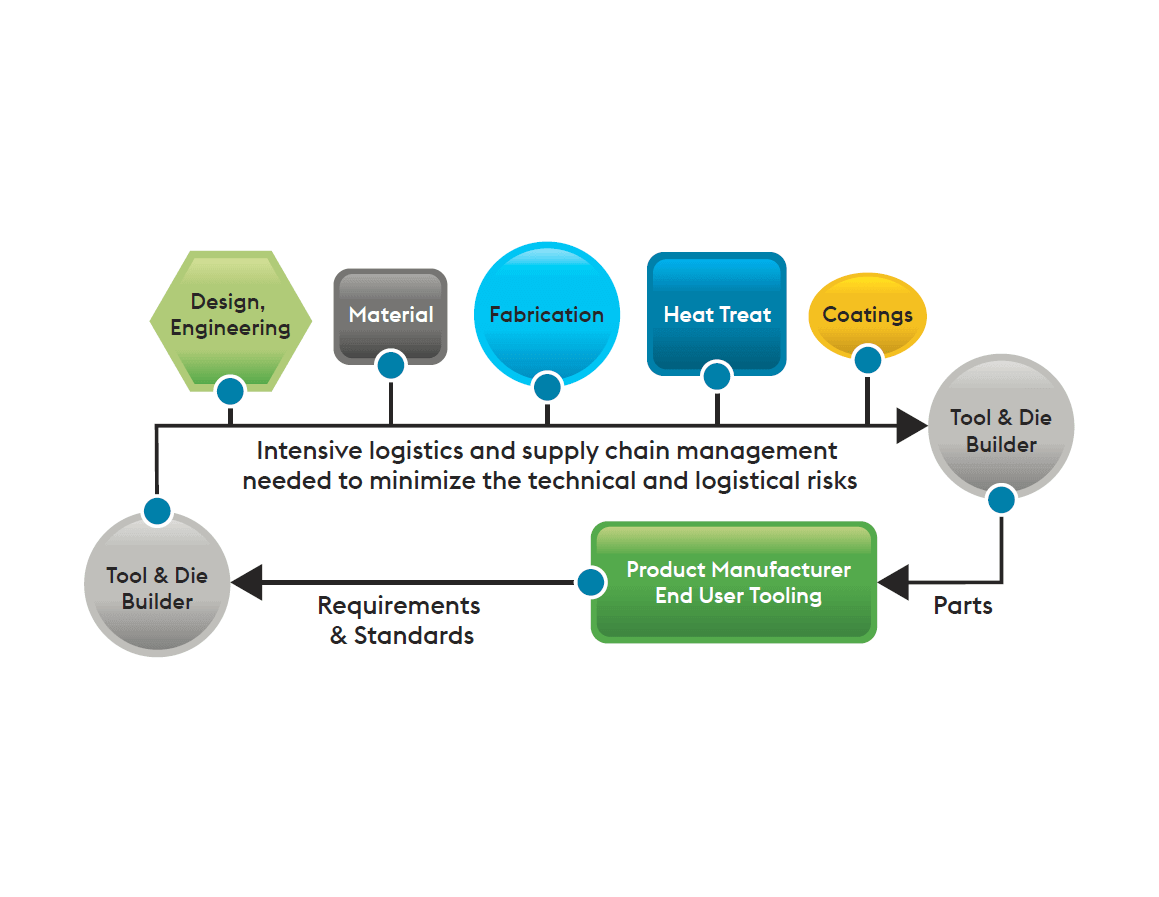

The traditional approach to the manufacture of core pins for die casting applications has been for the core pin manufacturer to rely on multiple sources during the various stages of production such as material or steel selection and additional ancillary steps such as heat treatment.

Reducing Supply Chain Waste

voestalpine now offers a complete integrated solution which delivers a core pin optimized to perform to a higher level in your application. With decades of experience helping customers solve complex metalworking problems, we are well poised to take performance responsibility for your system components. We choose the optimal material; whether that is traditional steel or one of our Additive Manufacturing (AM) hot work powders which are specifically designed for the working environments they experience.

Core Pin Design and Manufacturing Services

No other core pin manufacturer can promise the performance of voestalpine because we control the manufacturing process from the initial melt of the steel ingot to the delivery of the finished core pin to the customer. The failure of a single core pin can cause shut downs which puts on time deliveries at risk and can increase production costs. Companies that have worked with us have experienced significantly longer core pin life with no impact on part quality or production process parameters. In certain applications, core pins can be a constraint on productivity. For these environments, customers benefit from performance engineered core pins with specific characteristics, for example, improved heat transfer properties that enable optimized tooling performance such as reduced cycle times.