Produktkategorie: Engineered Products

voestalpine Sensorized Inserts

designed for pure performance

With rising demands for higher part quality, the need for effective process monitoring is increasing. For precise quality monitoring and process control, temperature sensors must be placed at critical points. However, practical constraints like limited accessibility and space due to cooling channels or ejectors often force compromises. This can result in reduced process insights, even with advanced measurement technology.

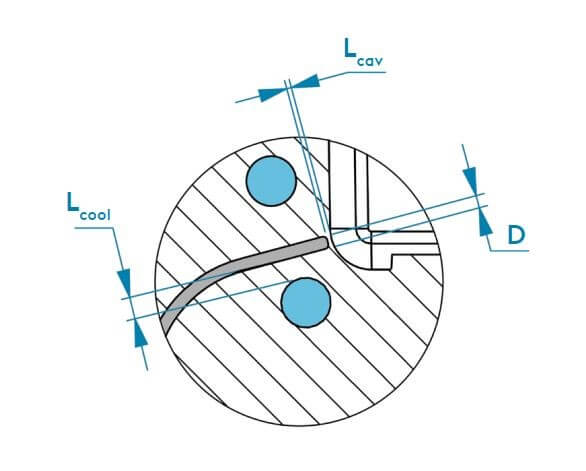

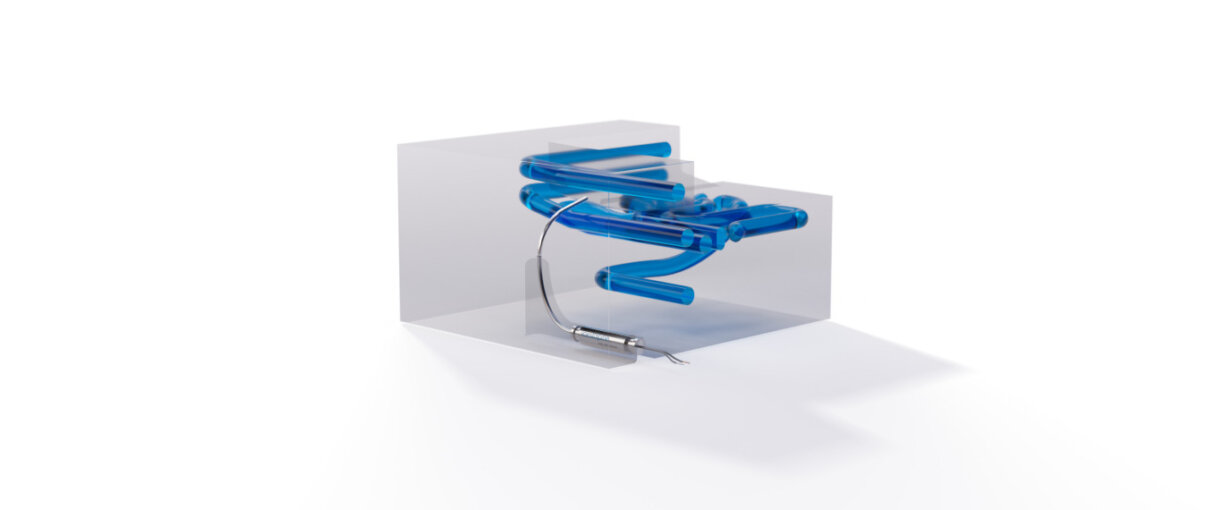

voestalpine Sensorized Inserts overcome these limitations by enabling the seamless integration of internal channels for sensor placement via additive manufacturing. Using our integration know-how, small diameter channels can be realised with precise positioning up to 0.5 mm from the cavity. This approach allows precise process monitoring at critical areas without sacrificing cooling performance.

Utilizing the design freedom of additive manufacturing, sensors can be optimally positioned between cooling channels and the cavity wall, eliminating the need for additional drilling efforts. Moreover, conventional thermocouples offer a cost-effective alternative, as they can be installed directly into the mold insert.

USE CASES

- Process monitoring – cavity temperature

- Process monitoring – blocked cooling channel

- Switchover for variothermal processes

Download datasheet ( under “Downloads” below) for more details!