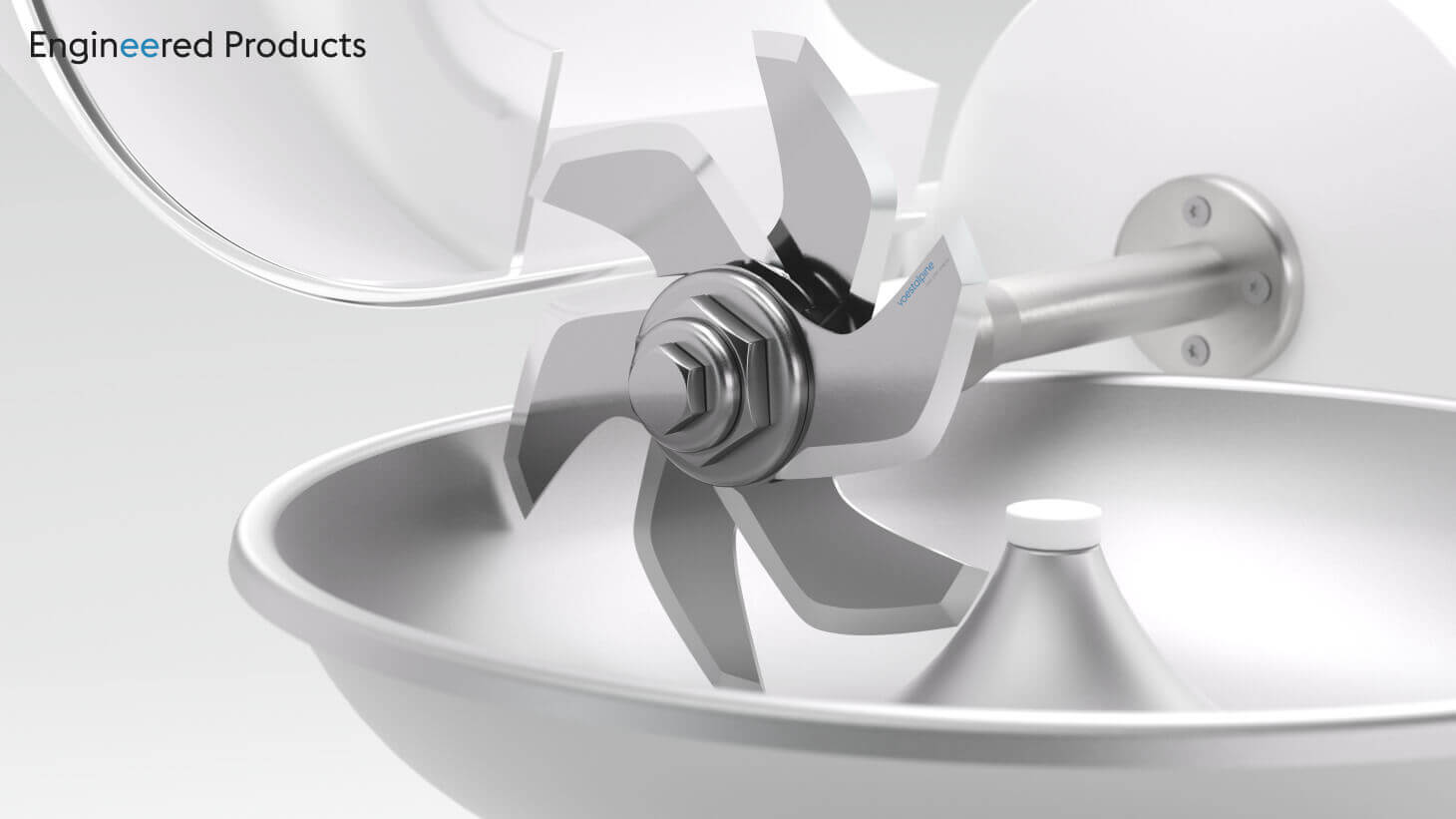

Sustainable Food Processing with voestalpine Bowl Cutter Knives

In this article we discuss how voestalpine Engineered Products enable our customers to make their food production more efficient and sustainable. We look at the remarkable performance of voestalpine Bowl Cutter Knives and how they can lead to ten times more throughput between regrinding cycles than standard industry knives. And we present an attractive offer to calculate just how much your food production can save by using the voestalpine solution.

The Future of Sustainable Food Processing

As the global market leader in tool steel, voestalpine High Performance Metals is committed to making our business as climate friendly as possible. Our sustainability framework inSPire is our vision for how we achieve this through our daily operations. With the integration of our products and services network for the food processing industry, we enable our customers to engage in sustainable initiatives. At the forefront of our innovative strategy lies the fundamental question-

How can we help make food processing more efficient and sustainable for our customers?

The answer can be found in our range of Engineered Products for Food Processing. voestalpine Engineered Products are ready-to-use, tailormade parts made from premium materials by BÖHLER / Uddeholm. Combined with technologies such as heat treatment, PVD coating, and even surface texturing, these products are designed to increase the production performance and output.

With a prolonged lifetime compared to standard industry solutions, these Engineered Products enable our customers to run a far more sustainable food processing operation through a range of benefits, including

- increased production efficiency

- decreased energy consumption

- reduced maintenance effort

- reduced production downtime

You can find out more about our range of Engineered Products for Food Processing here.

voestalpine Bowl Cutter Knives are Game-Changers!

voestalpine Bowl Cutter Knives are absolute game-changers that not only maximize equipment productivity but also make production far more sustainable. This recent addition to our Engineered Products range is used worldwide for many food products, with common applications including meat processing and pet food processing.

All too often, standard industry bowl cutter knives seriously underperform requiring frequent re-sharpening and replacement. By sticking to these standard cutting solutions, equipment users unwittingly play a losing game. The hidden costs would make for a disastrous scoreboard result.

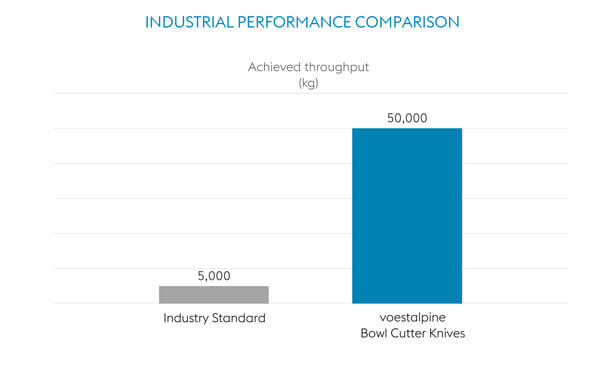

voestalpine Bowl Cutter Knives offer far superior performance. Through their premium materials, they offer an outstanding balance of high wear resistance, ductility (safety against cracks and breaks), and corrosion resistance. As shown in the figure below, they allow, for example, up to ten times more throughput on a boiled sausage production before regrinding is needed. Depending on the application these figures can go even higher. This allows for higher productivity and lower total cost of ownership.

With up to ten times more throughput per regrinding cycle, voestalpine Bowl Cutter Knives offer great savings through less regrinding effort and an extended life cycle. The higher wear resistance also significantly reduces food product contamination due to knife abrasion. The improved cutting performance leads to less machine wear and reduced energy demand.

The scoreboard results for customers using voestalpine Bowl Cutting Knives is enough to make any team cheer.

How Much Can You Save?

Find out for yourself just how much your food production can save by using voestalpine Bowl Cutting Knives! Contact our experts today to show you by using our ROI calculator just how much your production can save.