The construction industry is another area in which steel demonstrates its universal applicability. It opens up a wide range of choices, allows daring construction projects to be realized, and is 100% recyclable.

Around the world, our voestalpine companies offer a wide range of products and solutions:

Underground construction

Construction begins with the foundations and secure transport connections to the construction site. Only the most practical and efficient materials are used.

-

Solid foundations are the basis for any building or construction. Our Omega and Z-form cold-rolled sheet piles are essential for safe excavations. Their resilience and simple connections ensure the necessary protection for employees, construction equipment, and the work area—even for quay walls during hydraulic construction.

-

With their high quality standards, decades of experience, and specific market knowledge, our companies are ideal partners when it comes to the design and production of customized tubes for formwork.

voestalpine Sadef in Belgium is a valued manufacturer of cold-rolled tubes for formwork construction. Robust tubes and sections for the highest safety requirements in formwork construction are also produced at our Krems site in Lower Austria.

-

Our iron and steel production generates by-products which have valuable properties for the construction industry. Granulated blast furnace slag from pig iron production reduces the use of clinker in the cement industry, helping to reduce its CO2 emissions. Coarser slags, produced by air-cooling the slag from our plants, have high load capacities and angular grain sizes, just some of the features that make them ideal for use in road construction.

Building construction

Whether a residential, office, or production building, construction using our cold-rolled sections offers advantages in terms of safety, sustainability, construction time, and costs. Our production sites in the United Kingdom, Belgium, France, the Czech Republic, Brazil, and Austria provide projects all over the world with specific tube and section solutions.

Steel offers many advantages for the construction industry, including:

- the environmental benefits of permanent recycling and reuse;

- versatility;

- weather resistance; and

- pest resistance (e.g., compared to wood).

The seamless hot-rolled section tubes from voestalpine Tubulars used as components in halls, buildings, and bridge constructions provide the necessary stability.

-

Metal frame systems are used in countless construction projects. Our galvanized steel systems offer a fast, lightweight, and easy-to-build alternative to traditional block work or concrete. Systems from voestalpine Metsec, a pioneer in this market, can be found, among others, in the commercial construction, retail, healthcare, and education sectors.

voestalpine Metsec and its sister companies supply, among others, purlins and rafters, the longitudinal and cross beams used in roof structures. Its light gauge steel framing systems, SFS, comprise precisely coordinated elements for the construction of load-bearing steel structures. They are valued as quickly erected supports for insulation, exterior and interior cladding. The cold-rolled steel components are usually assembled at the construction site with bolted connections.

Construction profiles from voestalpine Sadef in Belgium offer a wide range of design options. The lightweight supporting structure is suitable in substructures made of steel, concrete, or wood, and is compatible with many types of cladding. The portfolio also includes elements for building fit-outs: reinforcements for doors and windows, frames for drywall, profile solutions for cable management, protective structures (ROPS & FOPS), etc.

System solutions for construction include:

- Metframe—a modern, prefabricated frame solution from voestalpine Metsec.

Quickly installed, BIM Level 2 compliant, waste-free, with high noise and fire performance, suitable for complex structures, can be used for a wide range of facade solutions, suitable even on narrow construction sites. - FlexBuild is a fast, weather-resistant, and economic building concept. This modular 3D system can be implemented like a kit.

With their high load-bearing capacity, the seamless hot-rolled section tubes from voestalpine Tubulars are ideal for use in structural construction. They are used in buildings, halls, and especially roof constructions.

- Metframe—a modern, prefabricated frame solution from voestalpine Metsec.

-

Highly durable and unique facade solutions as pre-materials as well as tubes/profiles complement our range of products for the construction industry. A wide range of colors and impressive effects such as wood in 3D optics create visible and tangible architectural highlights, all of which are sustainable, both for facades and indoor applications.

This is complemented by our materials for roofs and roof drainage. Like the facade solutions, they are based on colofer®, an environmentally friendly coated steel strip from voestalpine Stahl.

-

Regulating ventilation and air-conditioning are becoming increasingly important. Heating, ventilation, and air-conditioning systems, so-called HVAC applications, have become indispensable in residential, public, and commercial buildings. voestalpine Stahl supplies HVAC manufacturers with the materials they need: hot-rolled strip, cold-rolled strip, hot-dip galvanized strip, electrolytically galvanized strip, and colofer®, our organically coated steel strip. We supply colofer® plus in almost any color. It can be deep-drawn, bent, cut, and joined without losing its attractive appearance—removing the need for subsequent powder coating.

It is typically used in:

- heat pumps;

- water heaters;

- control cabinets;

- ceiling air-conditioning systems;

- cooling systems/air-conditioning systems;

- and much more.

-

Scaffolding has an important influence on the efficiency and safety of construction projects. Construction companies rely on our products, because precise and professional production ensures high product accuracy: Deviations of only a few millimeters would quickly compound to create unbridgeable gaps at scaffolding heights of 100 meters. Whether for new residential buildings or the reconstruction of historical monuments, our scaffolding components are reliable and sustainable.

Civil engineering: for tunnels, bridges, roofs

Special construction tasks require special solutions, not just in terms of the statics and construction, but also with respect to their visual appearance. These include steel bridge arches and stay cable bridges, as well as elevators, wind and hydroelectric power plants. Our products support their efficient and exceptional design.

-

High-tech tubes from voestalpine Tubulars for the Semmering Base Tunnel Our steel products create the secure backbone for bridges and ramps, tunnels, and retaining structures. Whether open or concealed, prestressing steel ensures optimal load distribution on bridges. Prestressing wire strands from voestalpine Wire Technology are used for prestressing in bridge construction, as rock anchors, and for stay cable bridges.

Cold-rolled profiles up to 25 meters in length, which are manufactured for instance by voestalpine Profilafroid in France and comply with all the required dimensional tolerances, are solid components for roadway bridge constructions.

Where traffic routes are forced to make their way through solid rock, high-strength mechanical tubes for construction ensure safe tunnel excavation. With its range of tubes made of high-strength quenched and tempered steel, our seamless tubes specialist voestalpine Tubulars offers the optimal equipment for secure tunnel stabilization. Their new square and rectangular VTS®-edgeTubes are also the optimal solution for bridge construction.

-

Prestressed concrete components allow the construction industry to erect elaborate roof and bridge constructions, or towers. We produce prestressing wire for challenging applications such as wind turbines: voestalpine Wire Austria supplies around 50 tons of high-strength prestressing wire for prestressing the concrete segments in each hybrid tower. This technology makes it possible to build taller towers on land, in turn ensuring better wind yields and a more secure supply of green electricity.

Prestressing wire is also used in concrete sleepers, as well as prefabricated elements, girders, and concrete pressure pipes.

-

Where height differences need to be simply and easily overcome, we supply the parts that keep elevators and escalators moving. Quality components including door tracks, door openings, braces, frames, and more are manufactured by the voestalpine Roll Forming Corporation in the USA.

Their innovative, roll-formed profiles play a role in ensuring the optimal design of office furniture for the workplace.

-

Whether for bridge structures, stadiums or major urban projects - when maximum load-bearing capacity, design freedom and durability are required, cast steel is the first choice. The cast nodes, column bases and special components from the voestalpine Foundry Group are structurally efficient and can be aesthetically integrated at the same time.

Shape cutting

The cut-shape facility of the voestalpine Steel & Service Center Group is a full-service supplier that produces high-quality cut shapes and cut sheets from heavy plates and hot-rolled strips. We offer a comprehensive service package:

- machining and forming

- edge finishing

- heat treatment

- express delivery from stock

- testing technologies

- demagnetization

- surface

- accreditation and certification

Construction machinery

Construction projects always present logistical challenges, such as transporting building materials and lifting heavy loads. Modern construction brings a growing demand for construction machinery. In order to keep their weight as low as possible, we offer solutions made of ultra-high-strength steels for heavy-duty lifting technology, wagons, articulated boom and mobile cranes, concrete pumps, and much more.

By reducing equipment weight, the lightweight construction concept saves real costs and ensures lower emissions. Stronger steels also enable smaller sheet thicknesses, also reducing the need for welding consumables.

You will also find a large selection of sheets in various formats at the voestalpine Form Cutting Center. Highly and wear-resistant sheets and other high-quality products are available from stock.

Materials and joining

We have adapted our broad materials portfolio to meet the diverse needs of the construction industry. When gravel and rubble need to be transported and the heaviest loads lifted, the tipping troughs and crane booms made with voestalpine steels prove their worth. We also have the right products for processing wood.

Reliable welded joints are essential to the safe implementation of construction projects. We provide the appropriate welding equipment and accessories for each application.

-

The special benefits of steel become clear during construction: its versatility, its ease of application, and its infinite recyclability. We are constantly improving the properties of our steel brands for the construction industry. For example, the high strength of our alform® allows a significant reduction in sheet thickness with the same load-bearing capacity. This advantage is also reflected in greatly reduced weld seam volumes.

voestalpine hot-rolled fine-grained steels for extreme use in the construction, sand, gravel, and cement industries are tailored to a wide variety of tasks and applications: abrasion-resistant for the construction of tipping troughs, chutes, and containers, and ultra-high-strength for crane booms. Thermomechanically rolled heavy plate is valued in building structures and bridge constructions.

-

The excellent weldability of voestalpine steels for the construction industry is one of the prerequisites for their universal applicability. Close cooperation between steel design and joining technology ensures the availability of optimal welding solutions from the voestalpine Welding Group, for example, using the alform welding system.

Air-conditioning systems have become standard equipment in many buildings. HVAC components are assembled using precision brazing with perfectly coordinated filler metals. We also offer solutions for this special area of the construction industry.

-

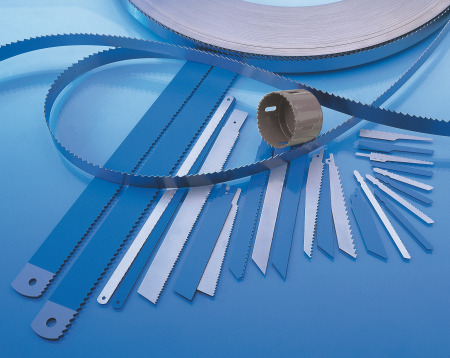

When it has to be wood, we also offer the products you need for handling and treating this sustainable material. Timber saw steel from the voestalpine Precision Strip Group is used globally—it is estimated that nearly every second metal saw blade worldwide is made from bimetallic strip from voestalpine Precision Strip.

One of our particular highlights is the blades used in producing oriented strand board (OSB), a sought-after product in the North American construction industry. They shred tree trunks into chips, which are then glued and pressed into panels for house construction.

Road safety

Road safety products from voestalpine Krems Finaltechnik enhance passive safety on Europe’s roads, and help protect human lives. We also offer bridge railings and game fences.

-

The guard-rails running along highways and motorways are hard to overlook. The “Kremsbarrier” brand refers to their origin in our Krems location. They are rammed or anchored to the roadway, and with a variety of restraint levels, are able to adapt the containment level to local needs and official requirements. To ensure complete safety, we also offer suitable system transitions between the different protection systems, or between roadside installations and on bridges, in tunnels, etc.

Crash cushions installed at key points also assist in avoiding serious accident outcomes. Bridge railings and comparable safety measures in areas of our transport network subject to fall hazards also serve to protect road users.

-

Walkways, pillars, tanks, and machines must all be protected, whether located outside or inside factory premises and parking garages. For this purpose, we offer a property safety module system that effectively protects people and objects from damage in all situations.

-

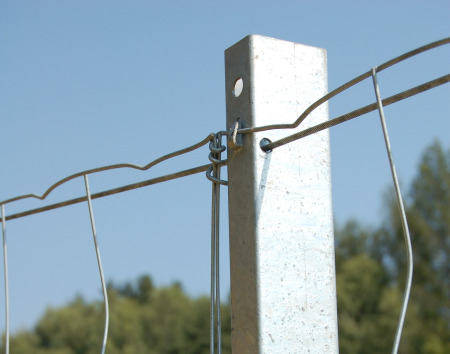

A common traffic and environmental protection concern is to protect wild animals from collisions with vehicles. For this purpose, the voestalpine Krems Finaltechnik product portfolio also includes durable, weather-resistant game fence posts for protective fences. Its streamlined appearance almost optically disappears into the landscape, while still offering the required stability.

Landscaping

Fences provide security. They are an indispensable part of modern transport solutions. To date, our “propiclo” system has been used to build tens of thousands of kilometers of fencing systems. Simple to install and with no concrete foundations, propiclo is suitable for use in all terrains and can be laid quickly and economically, covering distances of up to 1,500 meters a day.