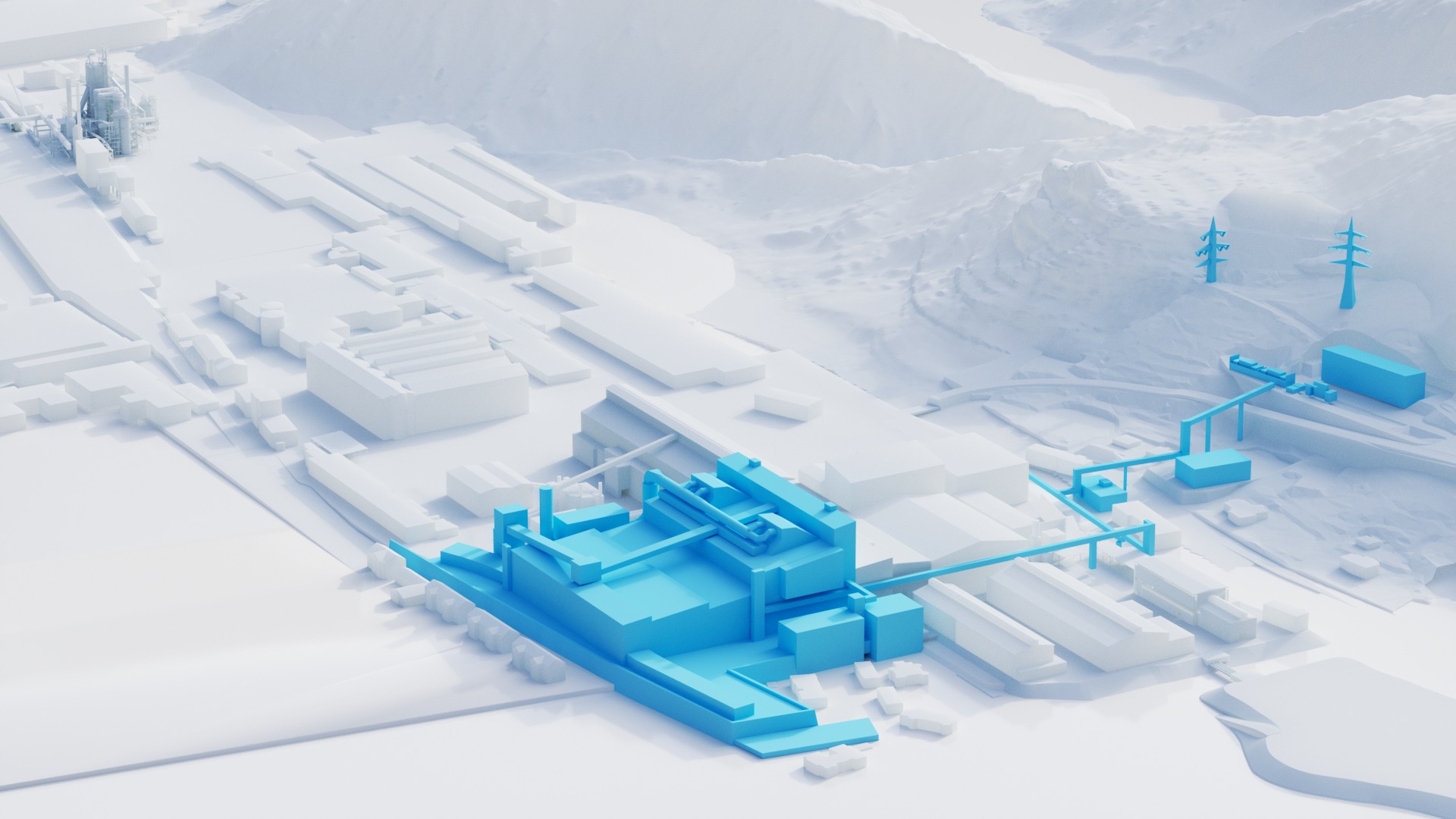

greentec steel at the site in Donawitz

In Donawitz, progress is already underway at the construction site, with facilities including the old continuous casting plant and the disused rail track being demolished. This is where the future EAF and new scrap hall will stand. The APG (Austrian Power Grid) and local provider Energie Steiermark are also at work installing the power supply infrastructure.

The dimensions of the greentec steel project in Donawitz are immense: the two construction areas are roughly equal in size to 10 football pitches (75,000 m2). Around 100,000 cubic meters of earth needs to be moved. Implementation requires a structured program consisting of 11 independent implementation projects involving a project team of around 75 internal and external experts.

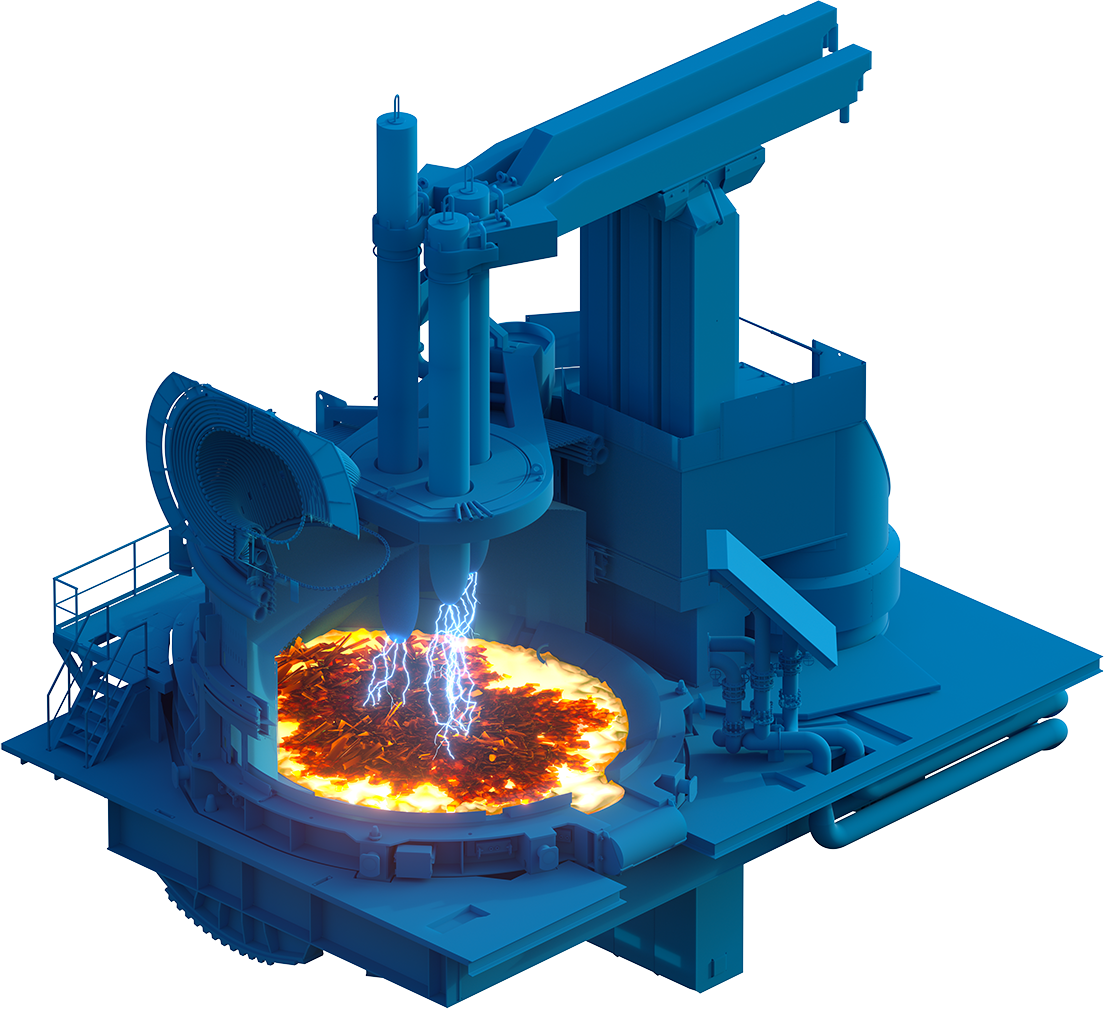

The plant engineering tender for the EAF in Donawitz was issued in summer 2023: Italian plant engineers Danieli & C. Officine Meccaniche S.p.A. will be responsible for the engineering, production, and commissioning of the EAF, using DIGIMELTER Technology.

New scrap hall

A new, closed, and soundproofed scrap hall able to store up to 27,000 tons of scrap (equivalent in weight to around 9,000 female elephants) is being constructed to supply scrap to the electric arc furnace.

220 kV supply

The supply of sufficient quantities of green electricity at economically viable prices as well as efficient grids are considered basic prerequisites for the decarbonization of steel production.

EAF

The construction of the electric arc furnace is an important milestone on the way to green steel production. Initial efforts have already begun and the final decision was made in 2023. The EAF in Donawitz will start operating in early 2027.

Scrap metal hall

Scrap metal – i.e. recycled steel – also plays an important role as a raw material in the operation of an electric arc furnace. As part of the innovative raw material concept, scrap metal is used together with HBI and pig iron.

All raw materials are transported to the electric steel plant as high-quality metal feedstock via automated charging systems. The new scrap hall located next to the EAF enables the supply of input materials.

Raw material storage (HBI)

The reduction of CO2 is made possible by a fundamental technological innovation: In addition to scrap and liquid pig iron, hot-briquetted iron, or HBI, will be used. Produced in a direct reduction process, iron ore for HBI is reduced with natural gas rather than coal and coke (in the future this will also be possible with hydrogen), which results in lower CO2 emissions.

Blast furnace

In the traditional blast furnace route, coke and coal are used as reducing agents. As part of our step-by-step plan with greentec steel, these are gradually being replaced by lower-carbon reducing agents. After the first electric arc furnace is commissioned, one blast furnace in Donawitz can be shut down.

voestalpine.jpg)