HIGH-QUALITY PROFILES WITH PROFILE

voestalpine BÖHLER Profile is internationally synonymous with high-quality steel profiles that not only impress with the best material properties, but also realize enormous savings potential in further processing. The focus on near-net-shape special profiles eliminates a large part of the waste that would be generated by milling and machining bar steel. This sustainable production approach has a positive effect on the material properties, protects the environment and the customer’s budget.

TAILOR-MADE SOLUTIONS – SPECIAL PROFILES FOR A WIDE VARIETY OF INDUSTRIES

Thanks to the high level of vertical integration and an R&D team, which is a pioneer in the field of special profiles internationally, voestalpine BÖHLER Profil is able to strike up development partnerships from a wide variety of industries with international customers. These partnerships often result in best practice solutions that define the standard of tomorrow in the market.

SUSTAINABILITY AT ALL LEVELS

At voestalpine BÖHLER Profil, sustainability is very important in the areas of environmental protection, occupational safety and energy efficiency. We have been carrying out targeted activities for many years to meet this requirement.

- steel is 100% recyclable

- reduction of CO2 emissions through special profiles

- boosting efficiency andsustainable resource conservation

- electricity self-sufficiency through the company’s own green power plant

- min. 2% annual reduction in overall energy consumption

- return & recycling of residual materials

- supporting measures for health protection

- behavior based safety

- behavior-based occupational safety

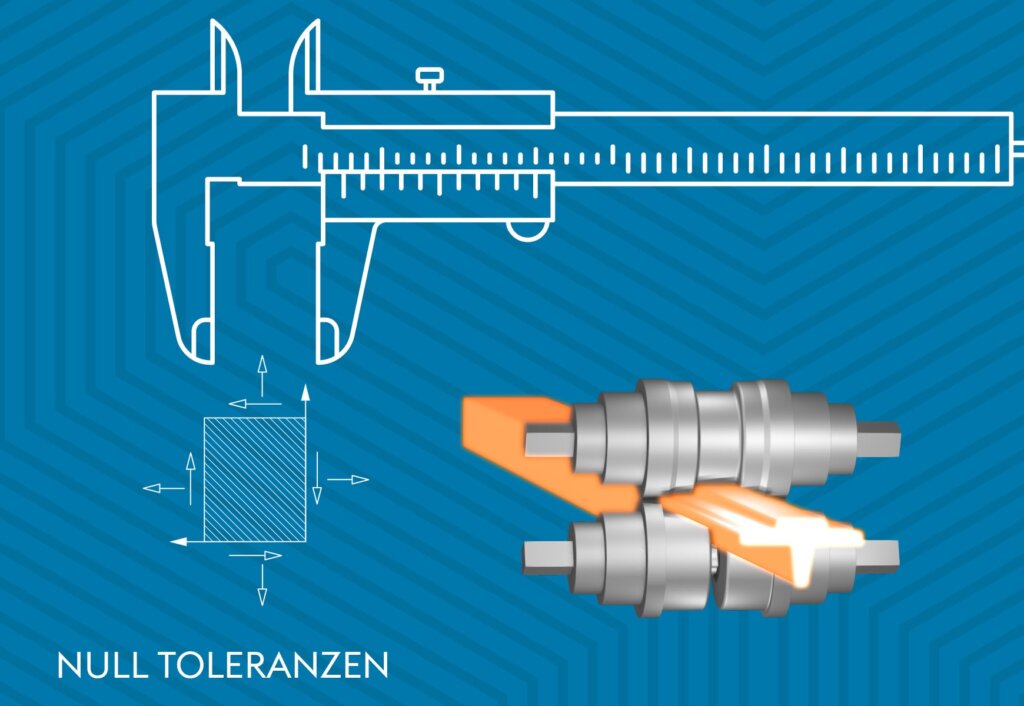

ZERO TOLERANCE FOR TOLERANCES

Depending on the dimension of the profiles, they are produced in different production plants using specially developed processes. While larger cross-sections receive their profile in the open rolling mill, smaller cross-sections are manufactured on the computer-controlled continuous rolling line. The material runs over several deformation stages or rollers and through a precisely controllable heating system. Profiles from voestalpine BÖHLER Profil do more than just meeting the highest demands on deformation and at the same time have the smallest manufacturing tolerances.

EACH PROFILE INDIVIDUALLY ADAPTED TO THE NEEDS

oestalpine BÖHLER Profil offers high-quality materials in top quality and responds to the individual needs of each customer. There are countless steel grades, but also nickel-based alloys, which are processed into intelligent profile solutions.

The configuration variants consisting of materials, melting types, designs, heat treatments, surfaces and more result in an individual and unique special profile for every customer.

The focus of product development is the consideration of the entire manufacturing process: from the raw material to the finished part of the customer. Only through the holistic view of the entire process chain an optimal finished part can be guaranteed.

CUSTOMISED ALLOYS

Durch die enge Zusammenarbeit mit dem Schwesterunternehmen voestalpine BÖHLER Edelstahl und anderen Partnern entstehen nicht nur hochwertige Profile aus unlegiertem Stahl, sondern auch aus Nickelbasislegierungen, die exakt den Vorgaben der Kunden aus den unterschiedlichsten Branchen entsprechen.