Production

Our advanced aerospace production services

Quality and Safety

The safety of our staff and the quality of our processes and products are of the utmost importance throughout the entire production area. We attain that quality with our securely integrated product portfolio ranging from the preliminary material through the whole forging process and conducting various customer-approved testing methods, all the way to machining and issuing aerospace-related certificates.

Our responsibility and our quality management attest to us providing the maximum degree of quality and safety for you as a customer.

Specialized and cutting-edge

Our entire product range is produced on two of the world’s largest screw presses, on counterblow hammers and in open-die forging. We specialize in the manufacture of high-quality die-forged parts made of titanium and nickel-base alloys, high, medium and low alloyed steels.

Flexibility with the most modern methods in toolmaking

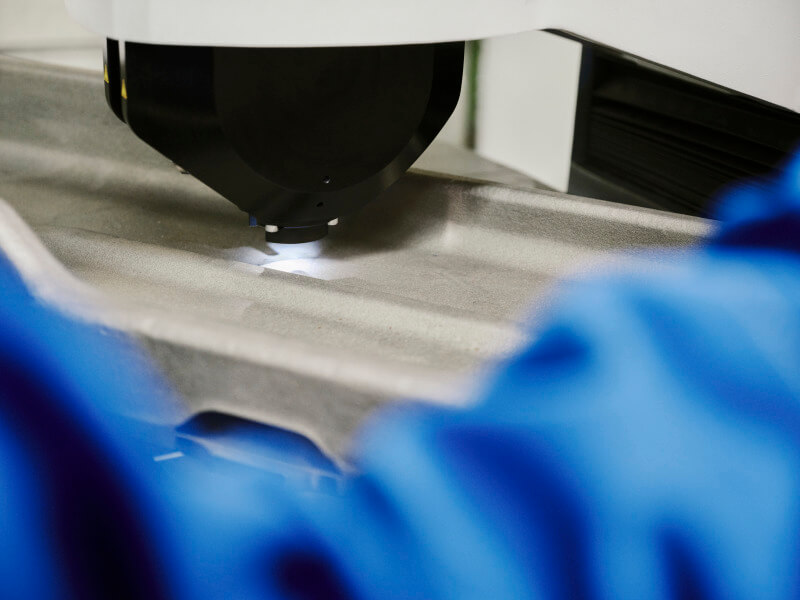

Each of our forgings requires a specifically defined production cycle and individually designed tools. Thanks to our in-house state-of-the-art toolmaking facilities we can guarantee you flexible and extensive cutting-edge solutions.

Our design engineers work closely with our experienced technical personnel in the production departments to determine which tools and materials are to be put to use. The size, weight and complexity of the components are taken into consideration.

Our Highly Efficient Production Processes:

Johann Tockner

Vice President Production

Phone: +43 50304 33 37128

Send e-mail

Our new pre-forming line operates with two forging presses, with a max. pressing force of 6,000 tons and 1,500 tons respectively, and 2 rotary hearth furnaces. The parts will be handled using 4 manipulators and an automatic toll changing system.

We offer flexible production processes on counterblow hammers and in open-die forging with a range of impact energy. Our facilities allow for the precise production of forgings with a working weight ranging from one kilo to more than 1000 kilos.

We work with two mechanical screw presses with a pressing force of 35,500 and 31,500 tons respectively; our 35,500 ton screw press is the largest in the world. These presses allow us to produce parts made of steel and titanium alloys at a maximum weight of 1,600kg for aircrafts and turbines.

In view of component stress, voestalpine BÖHLER Aerospace selects the right heat treatment to get the most out of each workpiece produced. Our special processes, conceived to comply with the strictest of specifications and requirements for heat treatment and the non-destructive testing of aerospace components, have been approved by PRI/NADCAP.

Material testing consists of diverse testing methods with which the behavior and the parameters of the materials samples or finished components (component testing) are able to be determined with regard to mechanical, thermal or chemical stresses.

At voestalpine BÖHLER Aerospace, we test materials and components on their purity, flawlessness and resilience. Our special processes for complying with the strictest of specifications and requirements for heat treatment and non-destructive testing of aerospace components have been approved by PRI/NADCAP.

voestalpine BÖHLER Aerospace is your technology partner from the forged part to the ready-to-assemble part. We ensure your competitiveness by managing the entire value chain, by reducing interfaces, lessening administrative efforts and increasing transparency. Our expertise in forging is second to none. With the same dedication, we are advancing our expertise in subsequent value chain steps, such as pre- and final machining as well as surface treatment.