Engine Disks

It’s all about rotation

The most advanced materials and processes for the most demanding applications

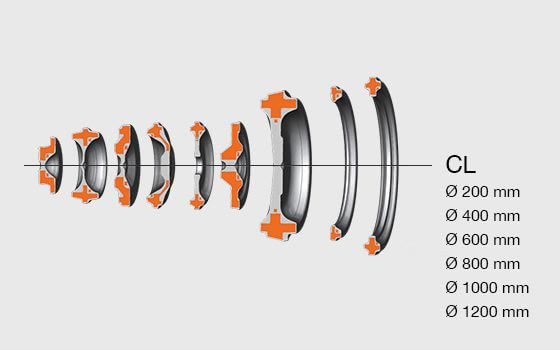

The jet engine disk technology has developed considerably throughout the past few decades and so have the simulation and modeling capabilities at voestalpine BÖHLER Aerospace.

Advanced computer simulation and finite element analysis in combination with diverse modeling capabilities, including thermo-kinetic simulation, are used to predict microstructure, residual stresses and mechanical properties. This is why we are able to guarantee process stability in serial production inspite of the demanding requirements on challenging disk geometries.

That is also the reason major OEMs and Tier 1 suppliers trust the voestalpine BÖHLER Aerospace disks, ranging from small helicopter disks weighing a few kilos, up to large disks with weights exceeding 350 kg and including high volume parts such as low pressure turbine disks for advanced turbofan engines for single aisle aircraft families.

Being committed to sustainability, we are proud to be a R&D partner for our customers by introducing new alloys and innovations in modeling to support the development of highly efficient next generation aircraft engines.

David Sallegger

Vice President Marketing & Sales

Phone: +43 50304 33 36795

Send e-mail

Florian Tatschl

Product Manager Engine Disks

Phone: +43 50304 33 37416

Send e-mail

Stefan Niederl

Product Manager Engine Disks

Phone: +43 664 88324387

Send e-mail