Steel: the recycling wonder

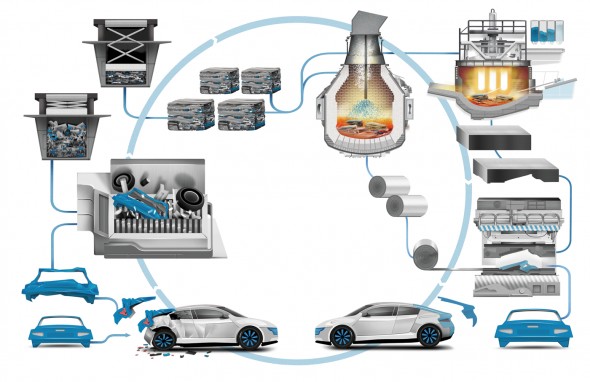

The steel industry is a pioneer in closing material cycles. Why? Because the material can be reused again and again with virtually no loss of quality. This is another reason why steel is one of the most recycled materials in the world.

- 3