From iron ore to high bay warehouse

- 4

voestalpine Krems Finaltechnik GmbH, based in Krems, Lower Austria, manufactures sophisticated product solutions in the storage technology sector (high bay warehouses and system racks) – including the planning, engineering, production, and assembly at the customer’s premises. The profiles themselves are manufactured by sister companies, including voestalpine Krems GmbH. The profiles are produced using high quality voestalpine steel from Linz. Consequently, the value chain within the voestalpine Group extends from iron ore processing right through to the completed end product – the high bay warehouse:

The first step is to produce the pig iron which is used by voestalpine Stahl GmbH in Linz to make the steel. 20,000 tons of iron ore are needed daily to produce pig iron; the iron ore comes from Erzberg in Styria, or is imported from countries such as the Ukraine, South Africa and Brazil. Around 25 percent comes from Erzberg, the remainder is imported.

At the coking plant ground coal is turned into coke. The coke is used in the blast furnace to smelt the iron out of the ore. In the blast furnace, the coke serves both as a reducing agent for the iron ore and as a fuel. Each year around 1.9 million tons of coke are required for the blast furnace in Linz. We produce 1.3 million tons in our own coking plant. The coking plant in Linz is the only one in Austria.

Iron ore is turned into liquid pig iron in the blast furnace through a continuous reduction and smelting process. The blast furnace is charged with alternating layers of burden components and coke. The iron ore is smelted down into liquid pig iron at a temperature of over 2,200°C. Once every two hours a hole is drilled in the bottom of the blast furnace to allow the 1,400°C pig iron to flow out – this is called tapping.

The pig iron is used to make voestalpine steel in the steel mill using the Linz-Donawitz process (LD process). The LD process was developed by voestalpine in 1952. Today two-thirds of all steel worldwide is manufactured using this process.

When the melt is ready, the steel is brought to the continuous casting line where it is drawn into a continuous length. After solidification, the lengths are cut into individual slabs. A slab weighs 30 tons, is 12 m long and 20 cm thick.

In the rolling mill the slabs are rolled into steel strips, 5.5 km in length.

Usually the steel strip is refined with a protective coating of zinc to protect it from corrosion and rust. This galvanized steel strip is then wound into coils (steel strip reels) and delivered for further processing.

The coated coils are transported from Linz to voestalpine Krems GmbH in Krems. Here the coils are slit before being formed and cut into steel profiles. Open or closed profiles are produced as required. Closed profiles are produced using continuous welding.

The steel profiles are then delivered to our affiliated company voestalpine Krems Finaltechnik where they are screwed together and welded.

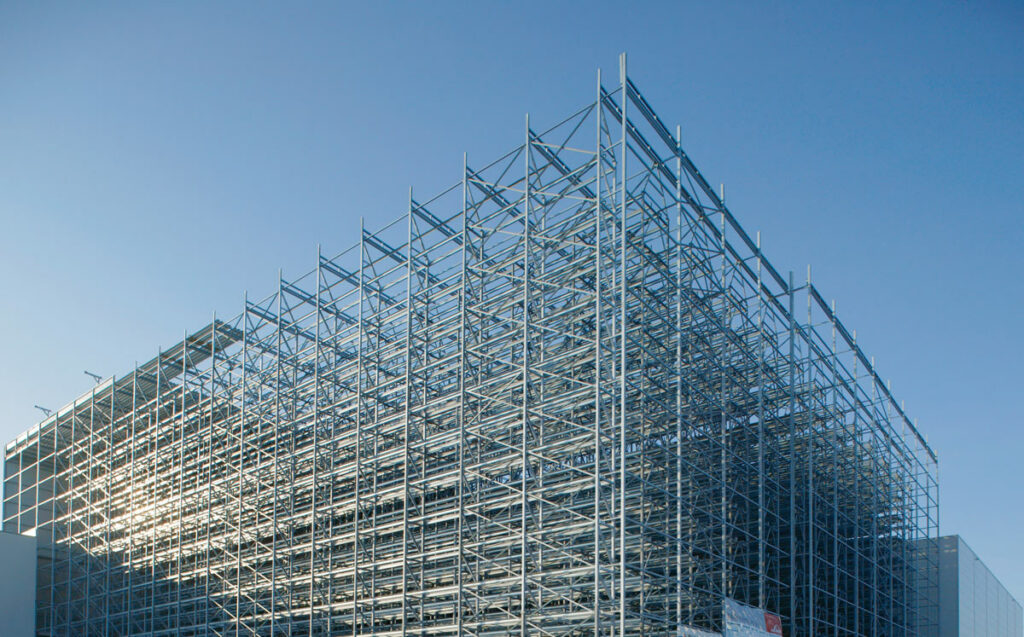

Finally the structures are built by voestalpine Krems Finaltechnik GmbH, and assembled as finished high bay warehouses on the customers’ premises. Assembly accounts for around 30 percent of the work of creating a high bay warehouse and takes around 12 weeks. High bay warehouse projects are implemented very quickly: on average it takes only 35 weeks from the awarding of a contract to its final completion.

From iron ore to completed high bay warehouse: the entire value chain stays within voestalpine.

Watch the video animation on Youtube.

Die voestalpine ist ein weltweit führender Stahl- und Technologiekonzern mit kombinierter Werkstoff- und Verarbeitungskompetenz. Die global tätige Unternehmensgruppe verfügt über rund 500 Konzerngesellschaften und -standorte in mehr als 50 Ländern auf allen fünf Kontinenten. Sie notiert seit 1995 an der Wiener Börse. Mit ihren Premium-Produkt- und Systemlösungen zählt sie zu den führenden Partnern der Automobil- und Hausgeräteindustrie sowie der Luftfahrt- und Öl- & Gasindustrie und ist darüber hinaus Weltmarktführer bei Bahninfrastruktursystemen, bei Werkzeugstahl und Spezialprofilen. Die voestalpine bekennt sich zu den globalen Klimazielen und verfolgt mit greentec steel einen klaren Plan zur Dekarbonisierung der Stahlproduktion.