Sustainable voestalpine steel in the wind

- 7

We need green electricity. But we cannot generate it ourselves on the scale we require, even though several of our subsidiaries around the world are covering their in-house demand for renewable energy. Instead, our innovative products are used to manufacture wind turbines which generate green electricity. These include wind farms on land, along the coast, and far offshore.

Without wind power we cannot achieve the necessary reduction in CO2 emissions. The International Energy Agency (IEA) predicts that by 2050, wind turbines around the world will generate almost 12,000 terawatt hours of electricity. This quantity would provide Austria with enough electricity for 150 years (based on figures from 2022).

By 2050, wind farms on land, along the coast, and far offshore should account for almost a quarter of global electricity generation. We are ready to play our role in driving this development. voestalpine has the sophisticated products needed to support all forms of wind power generation. That means we possess the know-how required to further exploit the potential of wind energy.

On larger wind turbines, the tips of the rotor blades cut through the wind at speeds of over 300 km/h. Only high-strength steels have the material properties required to operate at such speeds. Manufacturers of onshore (land-based) wind turbines state that steel accounts for roughly a third of the turbine’s total weight. Around 100 to 120 tons of steel are required per megawatt (MW) of capacity, and almost 1,000 tons for the most powerful onshore turbines currently in operation.

Steel is used in both onshore and offshore wind farms for:

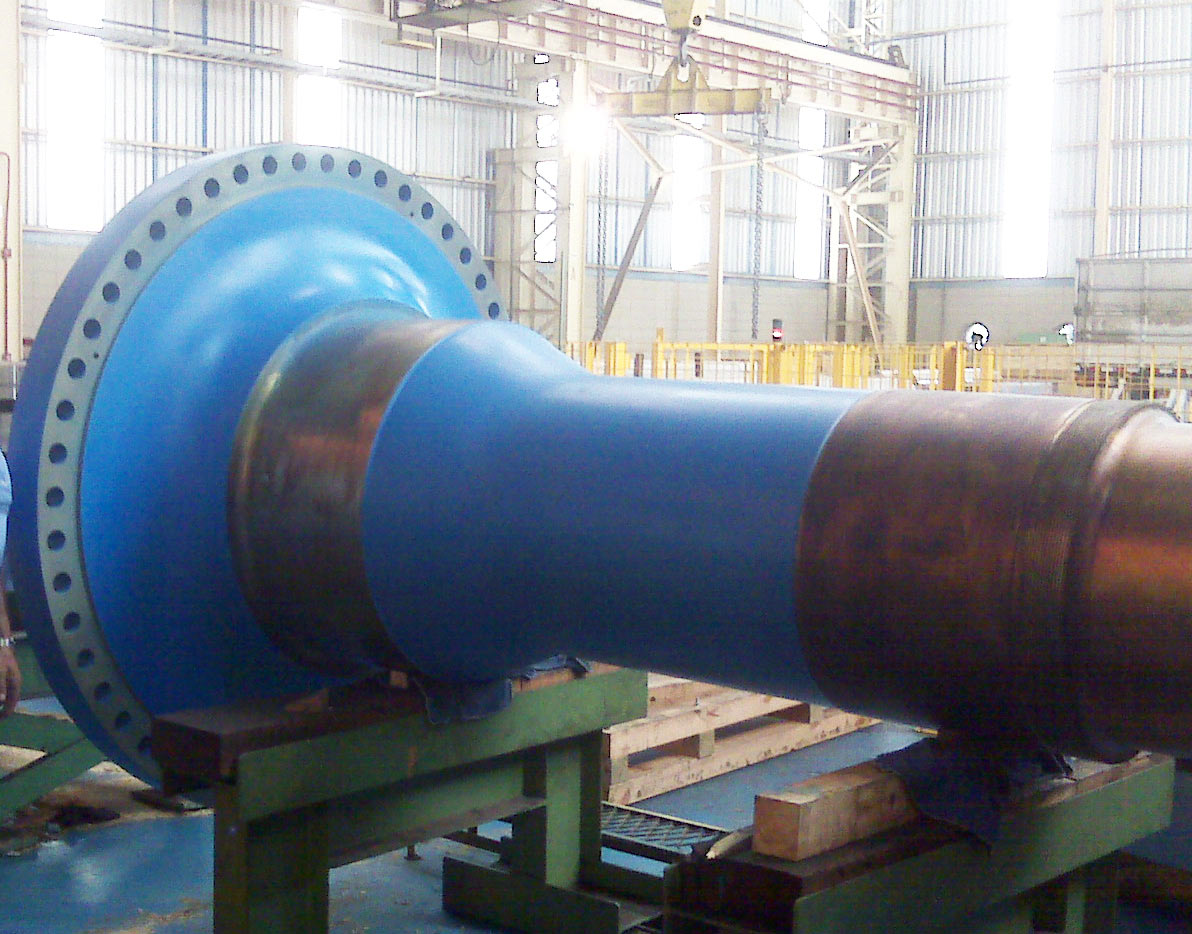

Steel is the dominant material used in all offshore installations along the world’s coasts. Even the “one-legged” monopile foundations with diameters of up around 8 meters consist of almost 1,000 tons of heavy plate. Steel is also used in the towers, generators, drive shafts and, where applicable, gearboxes. Brazilian voestalpine company Villares Metals is a supplier of enormous, ready-to-install turbine shafts. These shafts are used to build wind turbines in Brazil, the world’s 7th largest generator of wind power.

Demand for steel is rising as the use of wind power grows. During so-called “repowering”, higher capacity wind turbines replace their older and smaller predecessors. As a result, a wind farm may contain fewer yet taller wind turbines—because the higher you go, the stronger and more constant the wind. Anything reaching these heights needs to be firmly secured to the ground.

voestalpine Wire Austria supplies approx. 50 tons of high-strength prestressing steel wire per tower for prestressing the concrete segments. With the construction of larger turbines, e.g. in repowering, this tonnage is growing noticeably.

With its optimized wire products, the voestalpine company is already well prepared when it comes to tall wind turbines with more powerful generators. Today’s largest wind turbines are intended to offer a peak capacity of 18 MW. High performance and high efficiency electrical steel strip is a

vital component when it comes to generating this quantity of electricity using wind power. We supply this sophisticated product—isovac®—to major manufacturers of wind turbines.

voestalpine Stahl supplies 20 to 50 tons of electrical steel strip for every generator used in today’s standard-sized wind turbines.

voestalpine is renowned for its optimized products for offshore wind power. With constant winds and plenty of space, the sea is the ideal location for wind farms. At sea the wind conditions are optimal for 363 days of the year. The International Energy Agency (IEA) calculates that the global expansion of offshore capacities over the next two decades could eliminate 5–7 billion tons of CO2 emissions.

Combining strength and resilience, our thermomechanically rolled heavy plate offers the ideal mix of properties to withstand the stresses of operating at sea. voestalpine Grobblech GmbH manufactures extra heavy plate with individual weights of up to 60 tons for use in offshore wind turbines, and prepares the plates for effective welding.

In coastal regions, the wind turbines are anchored to solid foundations on the sea floor, mostly monopiles: Heavy plate formed into tubes of around 8 meters in diameter and rammed 50 meters and more into the sea floor. Together with the tower, nacelle, and rotor, these installations weigh around 3,000 tons.

voestalpine Stahl GmbH also offers solutions for highly resilient floating turbines which are becoming increasingly popular. Last but not least, thousands of tons of steel go into building platforms for the substations which transform the three-phase current generated by the turbines into direct current, which can be transported with far less loss. The foundational structures of these installations, such as BalWin2 on Germany’s North Sea coast, can easily require up to 10,000 tons of steel or more.

Substructure made from voestalpine heavy plate en route for assembly in an offshore wind farm(© SMULDERS).

Safety at sea is the basis for successful trade, which is why the welding on our steel constructions is fail-safe. voestalpine BÖHLER Welding consumables ensure the lowest possible error rate with minimal processing times. Erwin Gering, Global Key Account Manager for wind power understands the demands of the wind power sector.

Wind farms in deep waters which rise and fall with the waves rely on fail-safe welded connections.

Floating offshore turbines are designed to use the wind at sea to generate electricity even where the sea reaches depths of 60 meters and more. Wind farms have already been installed off the Chinese and American coasts, in the Bay of Biscay, in the Mediterranean, and elsewhere. In Europe, a further 3 to 4 GW in capacity is confidently expected to become available by 2030.

Floating wind turbines are subject to huge stresses on the connections between the floating substructure and the tower. The required level of stability is provided by the so-called “node” elements. The voestalpine Foundry Group is one manufacturer of these components.

Last but not least, the voestalpine Foundry Group supplies products essential to expanding offshore capacities: Special, cast crane hooks on installation vessels and platforms ensure wind turbines can be safely assembled at sea.

We plan to produce voestalpine steel with zero emissions from 2050. We can only achieve this goal when sufficient quantities of green electricity can be drawn from a powerful grid. Naturally, we are also relying on wind power. Since 2022, rotors on nine wind turbines have been supplying our Styrian sites with wind power. The wind farm on the Stanglalm provides us with 89 GWh of sustainably-generated electricity. This is green electricity which helps us reach our zero emissions goal as part of voestalpine’s greentec steel program.

5 MW wind turbines generate electricity for around 3,700 Austrian households each year.

100 rotations of the rotor blades is enough—in ideal winds, the Chinese H 260-18 generates the average annual amount of electricity consumed by an Austrian household in less than 10 minutes. At 18 MW, this is currently the world’s most powerful wind turbine.

1,375 wind turbines in Austria save around 3.35 million tons of CO2 emissions each year.

7.6 MW is the capacity of the most powerful onshore wind power plant Enercon E-126 EP8. 13–15 MW is the planned average capacity of any newly installed offshore wind farm from 2025.

10–13 m/s is the wind speed at which offshore wind turbines work most efficiently, i.e., the “sweet spot”.

18 cm is the diameter of the underwater cables which transport the electricity generated at sea to the land.

25 years is the average lifespan of a wind turbine.

15% is the forecast annual growth in wind power plants over the next five years, i.e., an extra 136 GW of capacity each year.

Die voestalpine ist ein weltweit führender Stahl- und Technologiekonzern mit kombinierter Werkstoff- und Verarbeitungskompetenz. Die global tätige Unternehmensgruppe verfügt über rund 500 Konzerngesellschaften und -standorte in mehr als 50 Ländern auf allen fünf Kontinenten. Sie notiert seit 1995 an der Wiener Börse. Mit ihren Premium-Produkt- und Systemlösungen zählt sie zu den führenden Partnern der Automobil- und Hausgeräteindustrie sowie der Luftfahrt- und Öl- & Gasindustrie und ist darüber hinaus Weltmarktführer bei Bahninfrastruktursystemen, bei Werkzeugstahl und Spezialprofilen. Die voestalpine bekennt sich zu den globalen Klimazielen und verfolgt mit greentec steel einen klaren Plan zur Dekarbonisierung der Stahlproduktion.