voestalpine and Automotive

- 2

voestalpine is two-thirds automotive, at least in terms of revenue (BY 2019/20): it generates 34% from customized products and innovations for prestigious automotive manufacturers and their suppliers. Today, the focus lies first and foremost on electromobility, with the group companies drawing on their extensive experience to develop brand new ideas which benefit both customers and the environment.

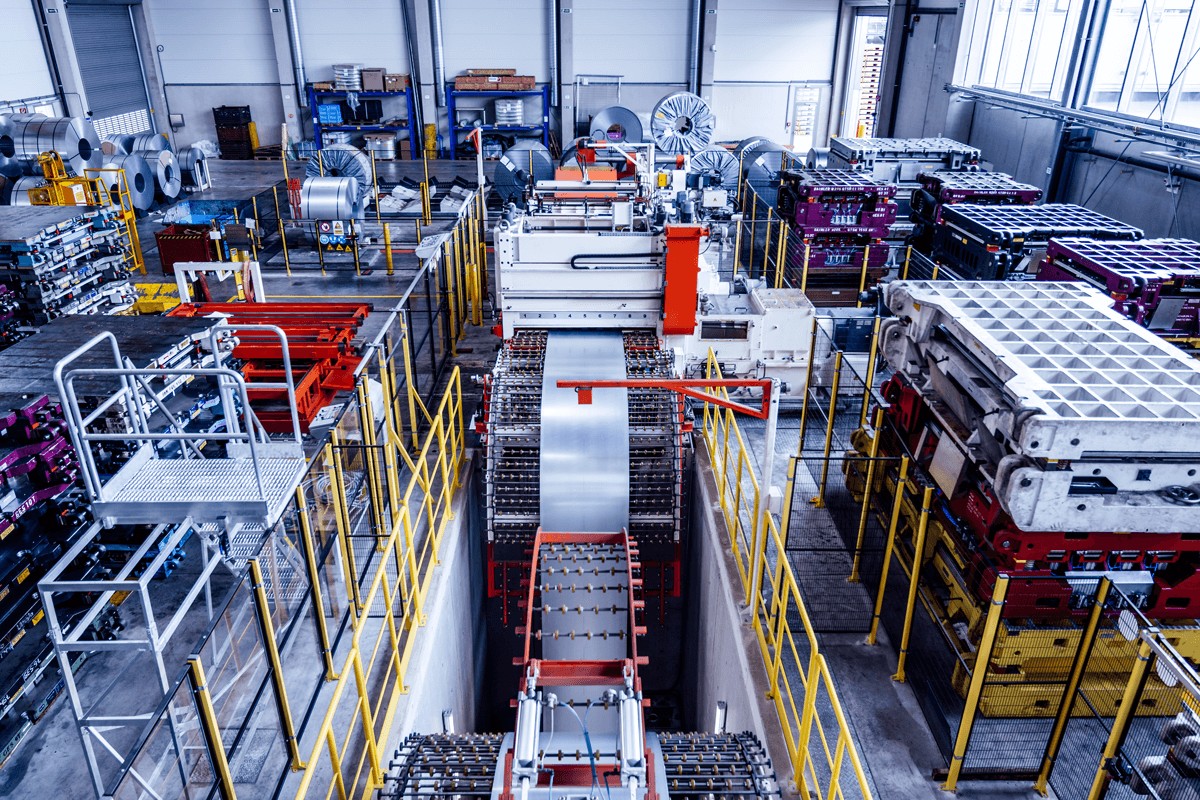

voestalpine is an important strategic partner to the automotive industry, especially in the premium sector. Working in partnership with its customers, it sets processing standards in fundamental areas of modern automotive production. Irrespective of drive technology, the product mix offered by the four voestalpine divisions covers the entire automotive sector.

Automotive innovations: voestalpine highlights

From the smallest spring to the entire component: in tires, drives, structural and safety parts, for forming and welding—voestalpine products are present in almost all automobiles.

voestalpine masters the challenges posed by rapidly changing automotive trends through innovative product ideas and a high degree of flexibility. Consulting firms predict that the global decline in automotive production over the past years is due to end in 2020, with e-mobility solutions playing a disproportionately large role in the market upturn. National and European regulations, a rethinking of society’s attitudes to mobility, and huge market changes should push new electric vehicle registrations over the 10 million mark globally by 2025. However, it should be remembered that the annual figures for newly registered vehicles with combustion engines (ICE) will still exceed that of electric vehicles until around 2040. Consequently, optimized ICE technologies will remain in demand for far longer than the next two decades.

Strategically, voestalpine is focusing on

Die voestalpine ist ein weltweit führender Stahl- und Technologiekonzern mit kombinierter Werkstoff- und Verarbeitungskompetenz. Die global tätige Unternehmensgruppe verfügt über rund 500 Konzerngesellschaften und -standorte in mehr als 50 Ländern auf allen fünf Kontinenten. Sie notiert seit 1995 an der Wiener Börse. Mit ihren Premium-Produkt- und Systemlösungen zählt sie zu den führenden Partnern der Automobil- und Hausgeräteindustrie sowie der Luftfahrt- und Öl- & Gasindustrie und ist darüber hinaus Weltmarktführer bei Bahninfrastruktursystemen, bei Werkzeugstahl und Spezialprofilen. Die voestalpine bekennt sich zu den globalen Klimazielen und verfolgt mit greentec steel einen klaren Plan zur Dekarbonisierung der Stahlproduktion.