Steel cycle: How scrap is turned into green steel

The conversion to “green” steel production means that significantly more scrap will be needed in the future. However, this increasing demand cannot be fully covered by new scrap (pre-consumer scrap). In future, it will therefore be necessary to make greater use of old scrap (post-consumer scrap), which has to be processed and sorted at great expense compared to new scrap, which is usually of the same type. This is the only way that scrap can be reused for the production of high-quality steel grades.

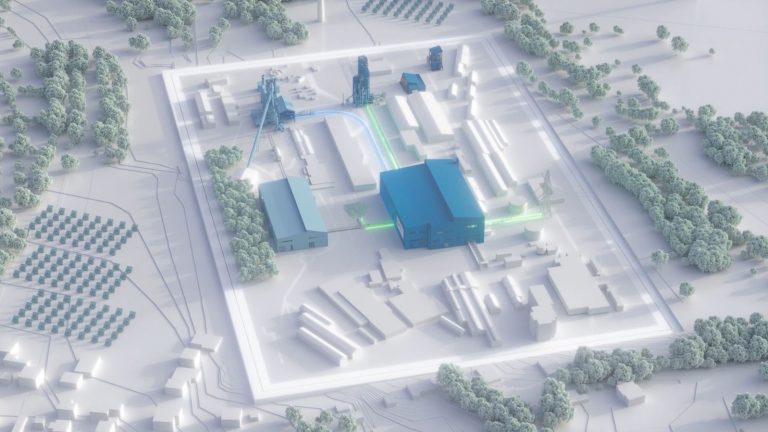

- 6