Food industry: voestalpine takes care of nutrition

From burger patties to coffee, a lot of voestalpine know-how is involved in the production of food and beverages. The Group supports safe, efficient, and sustainable nutrition.

- 5

From burger patties to coffee, a lot of voestalpine know-how is involved in the production of food and beverages. The Group supports safe, efficient, and sustainable nutrition.

From healthy muesli to all types of pasta: voestalpine know-how is often used in processing food and luxury foods. The company’s materials and engineered products provide the ideal basis for food processing because they keep food safe, preserve taste, and allow companies to work efficiently, reliably, and sustainably.

Burgers, bread, and bolognese—it would be almost impossible to process food in the necessary quantities without state-of-the-art technology. voestalpine provides the ideal materials and customized tools for many of the products on our daily menu:

In the food industry, resources must be used as efficiently as possible—including time and energy. Therefore, manufacturers look for materials that allow them to produce as continuously as possible. It should rarely be necessary to sharpen knives or to service equipment.

Extruders, for example, are subjected to high forces during kneading, mixing, and portioning. In Hagfors, Kapfenberg, and Wetzlar, voestalpine companies cut materials specifically for these applications. They minimize maintenance, for example sharpening grinders, and their optimal material design ensures safe and efficient production.

When processing sugar cane, the efficiency with which the sugar-containing juice is extracted depends directly on the wear-resistance of the components in the sugar mill.

Veal, pork, or chicken? You should be able to taste the difference. That’s why food processing is subject to high standards. The materials used in cutters, extruders, and knives influence the mechanical mixing and grinding process, not the taste.

Cleanliness and hygiene are prerequisites for a sustainable food supply. The properties of voestalpine stainless steel help the food industry meet these conditions.

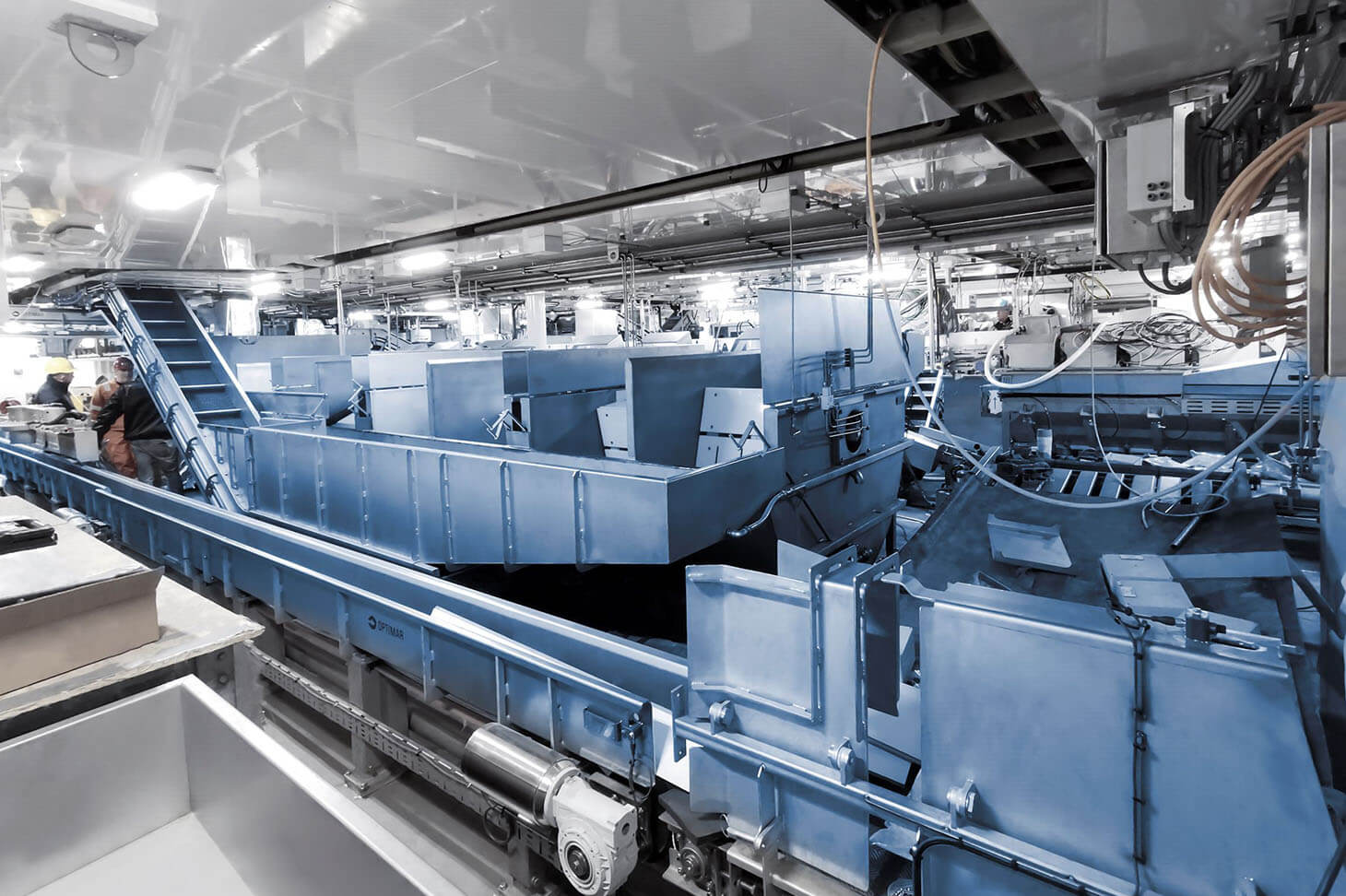

Corrosion is a threat both to food safety and the processing equipment. In some applications, it can be caused by the highly corrosive disinfectants used in cleaning or by the production environment itself. Fish processing plants, for example, are exposed to seawater and blood. The Swedish voestalpine company offers concepts for surface cleaning and passivation that restore the surfaces to their original condition.

The fact that you can drink fresh orange juice out of season and without additives or preservatives is thanks to an innovative technology. High-pressure pasteurization exposes fruit, juices, and meat to an ambient pressure of around 6,000 bar in a water tank. Der Effekt: Unlike flavors and vitamins, undesirable harmful organisms cannot withstand this pressure and the natural appearance of the food remains largely unchanged.

To be able to work with ultra-high pressures in pasteurization chambers, the food industry needs reliable armoring wire—especially shaped wire like that produced by voestalpine Wire Technology GmbH.

When you get a takeout with pizza, french fries, etc., the cardboard packaging probably came off voestalpine Precision Strip GmbH cutting lines. In purely statistical terms, every third to fifth piece of packaging that hits the global market—for food or medical products, banana boxes, or transport packaging — is punched, cut, and folded into shape using products from voestalpine Precision Strip. Enjoy!

Die voestalpine ist ein weltweit führender Stahl- und Technologiekonzern mit kombinierter Werkstoff- und Verarbeitungskompetenz. Die global tätige Unternehmensgruppe verfügt über rund 500 Konzerngesellschaften und -standorte in mehr als 50 Ländern auf allen fünf Kontinenten. Sie notiert seit 1995 an der Wiener Börse. Mit ihren Premium-Produkt- und Systemlösungen zählt sie zu den führenden Partnern der Automobil- und Hausgeräteindustrie sowie der Luftfahrt- und Öl- & Gasindustrie und ist darüber hinaus Weltmarktführer bei Bahninfrastruktursystemen, bei Werkzeugstahl und Spezialprofilen. Die voestalpine bekennt sich zu den globalen Klimazielen und verfolgt mit greentec steel einen klaren Plan zur Dekarbonisierung der Stahlproduktion.