greentec steel is contributing to a sustainable future

Switching from a coal-based process to green power is an essential step in achieving steel production with net zero CO2-emissions. From 2027, the innovative voestalpine hybrid plan will allow us to focus on a set of measures that can reduce our CO2 emissions by around 30% to 2030.

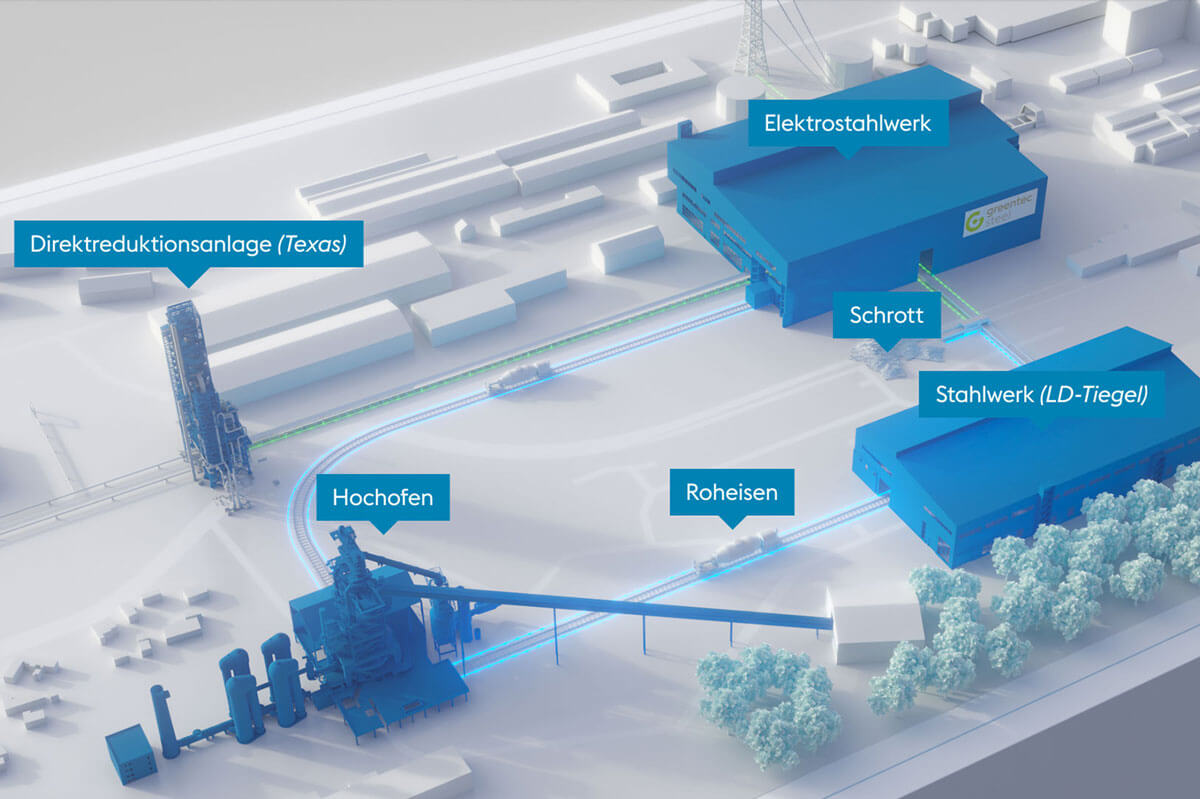

- 4