Everything on track: zentrak signaling and monitoring systems provide an overview

Railroads around the world should become more attractive, user-friendly, efficient, competitive, affordable, easy to maintain, efficient and sustainable. Ongoing diagnosis and monitoring of the entire rail infrastructure – from the track bed to the rolling stock – is a key component of this.

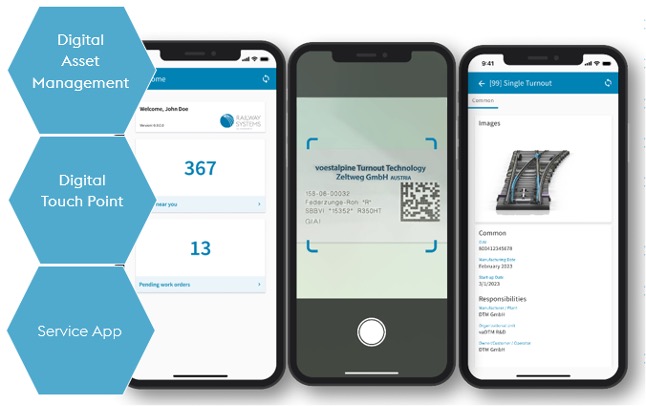

- 7